- Product Details

- {{item.text}}

Quick Details

-

Dimensions(L*W*H):

-

3.5*5*2m

-

Weight:

-

5 KG

-

Keywords:

-

paper bag flexo printing machine

-

FEEDING TYPE:

-

CHAIN FEEDING

-

speed:

-

50-60pcs/min

-

roller diameter:

-

300-800mm

-

type:

-

paper bag making machine with flexo printing

-

name:

-

corrugated cardboard pizza box ink flexo printing grooving machine

-

Flute type:

-

A-E

-

cardboard thickness:

-

2-12mm

-

colors:

-

1-5colors

-

keyword1:

-

flexo printing ink making machine

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

kspack

-

Voltage:

-

220/380/440

-

Dimensions(L*W*H):

-

3.5*5*2m

-

Weight:

-

5 KG

-

Keywords:

-

paper bag flexo printing machine

-

FEEDING TYPE:

-

CHAIN FEEDING

-

speed:

-

50-60pcs/min

-

roller diameter:

-

300-800mm

-

type:

-

paper bag making machine with flexo printing

-

name:

-

corrugated cardboard pizza box ink flexo printing grooving machine

-

Flute type:

-

A-E

-

cardboard thickness:

-

2-12mm

-

colors:

-

1-5colors

-

keyword1:

-

flexo printing ink making machine

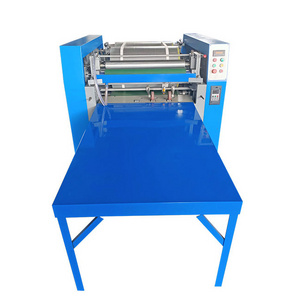

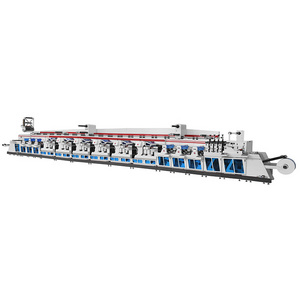

Corrugated Flexo Printing Machine Paper Bag With Flexo Printing Ink Making Machine

Functions and Characteristics: paper bag making machine with flexo printing

1. Whole machine electric parts was choose the domestic famous brand, good quality and steady.

2. Complete machine baffle and important parts used the temper for decrease the metal internal force; and that parts are made by high precision processing center and grinded by digit controlled grinder.

3. All the transmission axles and rollers are made by high-quality steel, and processed through temper and dynamic balance ; plated with rigid chrome and grinded surface.

4. All the transmission gears was used the 45# alloy steel, which is grinded after heat-treatment, and it was made by rubbing, it still maintains the high topping precision.

5. The whole machine undergoes the spray lubrication, intuitionist show setting, setting the double oil pipe balance system.

6 . Whole machine working interval adjustment, self-lock worm wheel and worm device, fast and convenient.

Function of Feeding Department:

1. Control faceplate function button putting concentrate and simple, operated convenient.

2. Electrically controlled the connecting and separated for the every unit with alarm to ensure the operator’s safety during its proceeding.

3. The light alloy aluminum back-kick feeding vacuum adsorption paper feed mechanism with several group of rolling bearing to ensure more steady machinery operation.

4. The left and right baffle, kick feeding, back baffle was adopted electric and computer numerical control adjustment.

5. Brush and the top suction device at the inlet which can clear away the impurity from the paper face to improve the printing quality.

6. Mainframe was controlled by the frequency conversion, start-up and cunning steady, which can save the power about the 30%.

7. Infrared photoelectricity counter can presetting the order paper quantity.

8. One lock function for whole machine, which can avoid the damaged the machine with error operation(The mainframe can not running when the every unit have not connected)

9. Pressure model elasticity feeding rubber roller, which can not to damaged the strength for corrugated cardboard.

10. Outside baffle add the flap function, which made the cardboard orientation more exact, avoid to waste.

11. Table by a welded steel plate and channel. Table plate thickness: 3.7mm. Channel is China's national standard of 10 # channel steel.

12. Table length 2380mm, 4 to 5 groups feed chain. Each chain has three push feeder.

13. Configuration 2 side cover. Made with 5 # angle iron. The forefront of the table with platen spring.

The technical parameter flexo printing ink making machine

|

M odel |

YSF 1200 |

YSF1450 |

YSF1650 |

|

D iameter of roller |

400MM |

480mm |

530MM |

|

T he max speed |

60PCS |

60pcs/min |

|

|

T he max feeding size |

1200X(2200-2800) |

14 50 x (2200-2800) mm |

1650X(2200-2800) |

|

Slot M in feeding size |

330X600MM |

350X 600 mm |

380X600MM |

|

E ffective printing size |

1200X(2000-2600) |

1450x ( 2 000-2600)( mm |

1650X(2000-2600) |

|

T he effective thickness |

3.5.7ply (2-12mm) |

3.5.7ply (2-12mm) |

3.5.7ply (2-12mm) |

|

P rinting plate thickness |

6±0.1 |

6±0.1 |

6±0.1 |

|

T he max depth of slot |

314 |

370 |

416 |

paper bag flexo printing machine

FINAL CARTON BOX O

FINAL CARTON BOX OF MACHINE:

THE BOXES FORMING PROCESS:

DIFFERENT CONFIGURATION PRINTER MACHINE:

A:

Tighten to container with steel wire rope and welded machine with container by angel iron

B

.

Main

corrugated box

machine

s

and un-coiler is naked(If you need we can also packed with water-proof plastic)

C.

W

ooden case and container with international delivery standard model

Our company service system :

Pre-sales service

1. W elcome to customers visiting our factory for seeing machines and inspect factory

2. A fter machines are finish ,supplier also can supply the training of machines for buyers for free After-sale service

1. With machine spare parts for 1-2 years ,no need buy new parts

2. Machine warranty time 2 years

3. W hen delivery machines will with operation manual for machines

4. S upplier sellers online 24hours ,also can contact by Skype ,Email ,whatsapp ,wechat ,phone calling ....

5.s upplier can supply technical abroad for installation and training ,but need buyer bear all charges,include the tickets,meals ,hotel,traffic etc.