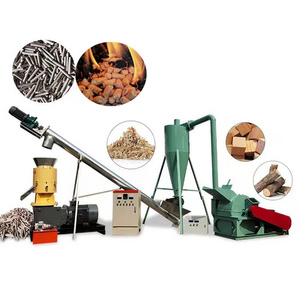

Bolida is a professional manufacture for biomass pellet machine, wood chipper, rotary dryer, biomass wood pellet line.Bolida offer turnkey solutions for pelleting plans/Wood pellet plant, complete units or single process lines such as; -Raw Material Processing; Including(Debarking-Chipping-Wet Grinding) Debarker/Splitter/Wood Chipper /Diesel Wood Chipper/Chaff Cutter /Wet Hammer Mill/Crushers -Thermal Drying Including Completely Drying line(Drum Rotary dryers/Triple Dryers/China Stain/Chamber/Steel Frame/Chimmey/Pellet Burner -Pellet Production Including Pellet Mills/Hammer Mills/Coolers/Sieves/Packing Machines/Automatic Control System/Pulse Dust System.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Power:

-

55kw

-

Dimension(L*W*H):

-

2755x1165x2100mm

-

Weight (KG):

-

5000

-

Product name:

-

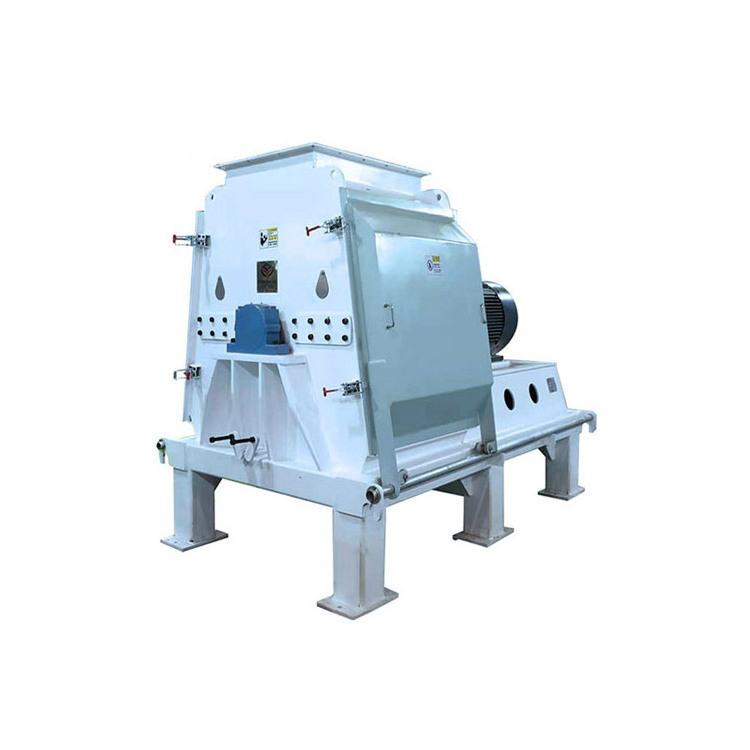

wood hammer mill

-

Function:

-

grinding

-

Keywords:

-

Sawdust Wood Hammer Mill

-

Brand:

-

Bolida

-

Main Power:

-

90kw

-

Related machine:

-

Biomass Pellet Machine

-

Hammer:

-

144

-

After-sale Service:

-

1 year

-

Capacity:

-

3-4ton/h

-

Model:

-

YMFS65x100

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BOLIDA

-

Marketing Type:

-

New Product 2023

-

Voltage:

-

380v

-

Power:

-

55kw

-

Dimension(L*W*H):

-

2755x1165x2100mm

-

Weight (KG):

-

5000

-

Product name:

-

wood hammer mill

-

Function:

-

grinding

-

Keywords:

-

Sawdust Wood Hammer Mill

-

Brand:

-

Bolida

-

Main Power:

-

90kw

-

Related machine:

-

Biomass Pellet Machine

-

Hammer:

-

144

-

After-sale Service:

-

1 year

-

Capacity:

-

3-4ton/h

-

Model:

-

YMFS65x100

Products Description

What is Wood Hammer Mill?

The high-efficiency wood hammer mill is widely used to crush various biomass wood chips and straw materials. The motor and the rotor are directly connected through a coupling, and the rotor can rotate in both positive and negative directions after the dynamic balance test. The raw material enters the crushing chamber and is crushed by the impact force generated by the high-speed rotating rotor. There is no dead angle in the crushing process. The granularity of crushed materials can be changed by changing screen plates with different apertures to obtain qualified crushed materials.

High efficiency hammer mill working principle is that the raw material go into the grinding room, then will be grinding by the impact force and shear force caused by high speed rotating rotor and collision force caused by the high speed rotating rotor, then pass through the screen to get the eligible products.

Product Paramenters

1. The motor connect rotor directly, the rotating speed can be 3000r/min, lower power loss and higher efficiency.

2. Discharge from both sides, increased the discharge area and improved capacity.

3. The machine body adopts unique structural design, discharge smoothly with seamless.

4. The particle of screen can be adjusted, ensure finished products requirement.

5. Work with Cyclone and Bag Dust Collector, more better dedusting efficiency.

2. Discharge from both sides, increased the discharge area and improved capacity.

3. The machine body adopts unique structural design, discharge smoothly with seamless.

4. The particle of screen can be adjusted, ensure finished products requirement.

5. Work with Cyclone and Bag Dust Collector, more better dedusting efficiency.

|

Model

|

Production Capacity(t/h)

|

Motor Power(kw)

|

Overall Dimension(mm)

|

Hammer

|

|

YPFS65*55

|

1-2

|

37/45

|

2300X1165X2100

|

72

|

|

YMFS65*75

|

2-3

|

55/75

|

2755X1165X2100

|

108

|

|

YMFS65*100

|

3-4

|

90/110

|

3100X1165X2100

|

144

|

|

YMFS120*75

|

4-6

|

132/160

|

3475X1860X2906

|

108

|

|

YMFS120*100

|

6-8

|

160/220

|

3145X1820X3060

|

144

|

|

55kw Pulse Dust Collection Hammer Mill

|

|

|

|

|

||||

|

Item

|

Model

|

Machine Description

|

Qty

|

Power

(kw) |

||||

|

Belt

Conveyor |

YPSJ60B

|

Transport the material in to

hammer mill, Length:8m |

1

|

2.2

|

||||

|

Frequency

Convertor |

INVT

|

To adjust the feeding speed of belt conveyor

|

1

|

/

|

||||

|

High

Efficiency Hammer Mill |

YGFC65×75

|

Power:55kw;Capacity:2-3t/h

Hammers:108pcs ;Screen:10mm |

1

|

55

|

||||

|

Single Shaft U type Screw Conveyor

|

YULS300x5

|

Discharging raw material

|

1

|

3

|

||||

|

Fan

|

4-72-3.6A

|

Discharging raw material

|

1

|

4

|

||||

|

Pulse Dust

Collection |

YMCC48×Φ135

|

Remove the dust

Fine cloth bag, good filtering effect. |

1

|

/

|

||||

|

Electric Control Cabinet |

DELIXI brand

|

Control the feeding speed of material

|

1

|

/

|

||||

|

Discharging Belt Conveyor

|

YPSJ60B

|

Discharging the material, length: 6m

|

1

|

2.2

|

||||

Raw Material and Application

Wood hammer mill can crush a wide range of raw materials, such as wood chips, wood shavings, straw, rice husk, grass, peanut shells, corn cob and other related materials.

Wood Chips

Straw

Peanut Shell

Corn Cob

Details Images

Advantage of Bolida Wood Hammer Mill

The motor is directly connected to the rotor, the rotating speed is 2950-3000 rpm, the frequency of material beating is higher, and the efficiency is faster.

The rotor has passed the dynamic balance test, so that the vibration of the hammer mill is smaller and the noise is low.

The screens are manufactured from high-quality carbon steel for long wear life; Large screen area, high output. The sieve plate can be changed with different holes.

The rotor has passed the dynamic balance test, so that the vibration of the hammer mill is smaller and the noise is low.

The screens are manufactured from high-quality carbon steel for long wear life; Large screen area, high output. The sieve plate can be changed with different holes.

Hammer

Monitor the current, if current exceeding the set value, automatically stop feeding, so as to protect the main motor.

Rotor

Real-time monitoring of bearing temperature, high temperature warning to prevent bearing damage.

Screener

The hammers are manufactured from high-strength carbon steel and finished with industry-leading hardfacing technology for

optimized grinding, used positive and negative, extending serving life.

optimized grinding, used positive and negative, extending serving life.

Customer Cases

Packaging and Delivery

Shandong Bolida Machinery Co., Ltd

Certifications

Our company has gained ISO9001-2000 Certification,CE Certification,SGS Certification patent etc.Products cover the environmental carbon, biomass,urban and rural environment,culture and other fields.There are five main series: the biomass compression molding equipment, garbage disposal equipment for urban and rural ,organic fertilizer equipment, Feeder Equipment and Environmental protection equipment .

BOLIDA Hot Products

Contact information

Contact Person: Julia Zhu

Email: Julia(at)rotexmaster.cn

Email: Julia(at)rotexmaster.cn

Mobile/Whatsapp/Wechat: +86 15508693992

Website: www.pelletlinesolutions.com

Address: Caofan Town, Zhangqiu, Jinan City, Shandong Province,China

Website: www.pelletlinesolutions.com

Address: Caofan Town, Zhangqiu, Jinan City, Shandong Province,China

Hot Searches