- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

CMIENSEM

-

Model Number:

-

YC

-

Junction box material:

-

Aluminum alloy baking paint

-

Protection:

-

IP65

-

Installation mode:

-

Vertical or horizontal

-

Voltage:

-

22-60VDC, 22-265VAC, 50/60HZ

-

Power:

-

DC-3W(MAX)AC-15W(MAX)

-

Connection specifications:

-

1 "PT teeth (customizable), 2" sanitary joints, flanges

-

Output contact:

-

DPDT5A/250VAC or NPN/PNP

-

Induction rod material:

-

SUS304/316

-

Temperature:

-

-40℃-130℃

-

Pressure:

-

-1-40bar

Quick Details

-

Grade:

-

DIY, Industrial

-

Warranty:

-

1 year

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

CMIENSEM

-

Model Number:

-

YC

-

Junction box material:

-

Aluminum alloy baking paint

-

Protection:

-

IP65

-

Installation mode:

-

Vertical or horizontal

-

Voltage:

-

22-60VDC, 22-265VAC, 50/60HZ

-

Power:

-

DC-3W(MAX)AC-15W(MAX)

-

Connection specifications:

-

1 "PT teeth (customizable), 2" sanitary joints, flanges

-

Output contact:

-

DPDT5A/250VAC or NPN/PNP

-

Induction rod material:

-

SUS304/316

-

Temperature:

-

-40℃-130℃

-

Pressure:

-

-1-40bar

Tuning fork type liquid level switch .

The YC tuning fork type material/level switch uses a piezoelectric component to generate a vibration wave, which changes the tuning fork when the measured medium contacts the fork

The frequency of the amplitude is detected by an intelligent control circuit and converted into the corresponding output signal.

For example :(Realy.NPN.PNP)

Product features

•

Elongated length up to 3m.

•

DPDP SPDT Relay/NPN/PNP output

•

Wide power input 20-250VACNDC, 50/60HZ

•

All metal construction, strong and durable

•

With automatic learning function, through the key, without calibration, can learn different media densities

•

The fork vibration amplitude is large, the amplitude can reach more than 10mm, can shake off the low viscosity local hanging material on the induction rod,

Prevent misoperation

•

Super bright red LED light provides a more convenient and immediate warning effect for site personnel's material level monitoring

•

Can be used for liquid, powder, pellet, thick material detection

|

Junction Box

|

Stainless Steel (IP65)

|

|

Installation method

|

vertical or horizontal

|

|

Voltage

|

22-60VDC, 50/60HZ

|

|

Gonghao

|

DC-3W (MAX)

|

|

Connection specification

|

G3/4" tooth (customization is acceptable)

|

|

Output contact

|

SPDT 5A/250VAC or NPN/PNP

|

|

Induction bar material

|

SUS304/316

|

|

Operating temperature

|

-40℃-100℃ Operating pressure: -1-40bar

|

|

Insertion length

|

45MM (customizable unit: mm)

|

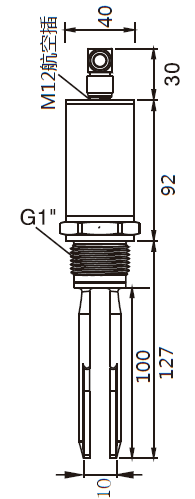

YC150

Minor Tuning Fork Standard

Junction box: Stainless steel (IP65)

Installation mode: Vertical or horizontal

Voltage :22-60VDC, 50/60HZ

Credit :DC-3W(MAX)

Connection specification :G1 "teeth (customizable)

Output contact :SPDT 5A/250VAC or NPN/PNP

Induction rod material :SUS304/316

Interface :M12 aviation plug

Operating temperature :-40°C-100 °C

Operating pressure :-1-40bar

Insert length :100MM(customizable unit :mm)

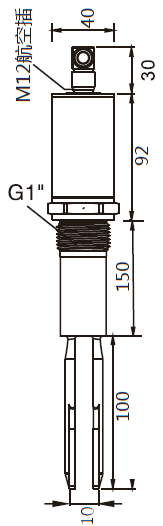

YC151

Small Tuning Fork Elongated

Junction box: Stainless steel (IP65)

Installation mode: Vertical or horizontal

Voltage :22-60VDC, 50/60HZ

Credit :DC-3W(MAX)

Connection specification :G1 "teeth (customizable)

Output contact :SPDT5A/250VAC or NPN/PNP

Induction rod material :SUS304/316

Operating temperature :-40° C -100 ° C

Operating pressure :-1-40bar

Insert length :250MM(customizable unit :mm)

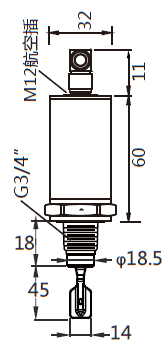

YC160

Short Fork Standard

Junction box: Stainless steel (IP65)

Installation mode: Vertical or horizontal

Voltage :22-60VDC, 50/60HZ

Credit :DC-3W(MAX)

Connection specifications :G3/4 "teeth (customizable)

Output contact :SPDT5A/250VAC or NPN/PNP

Induction rod material :SUS304/316

Operating temperature :-40° C -100 ° C

Operating pressure :-1-40bar

Insert length :45MM(customizable unit :mm)

YC161

Short Fork Sanitary Joint Type

Junction box: Stainless steel (IP65)

Installation mode: Vertical or horizontal

Voltage :22-60VDC, 50/60HZ

Credit :DC-3W(MAX)

Connection specifications :1 inch sanitary connector (can be customized)

Output contact :SPDT 5A/250VAC or NPN/PNP

Induction rod material :SUS304/316

Operating temperature :-40° C -100 ° C

Operating pressure :-1-40bar

Insert length :45MM(customizable unit :mm)

YC180

Explosion-Proof Standard

Junction box: Aluminum alloy paint (IP65)

Installation mode: Vertical or horizontal

Voltage :22-60VDC, 22-265VAC, 50/60HZ

Power :DC-3W(MAX)AC-15W(MAX)

Connection specifications :G1-1/2 "teeth (customizable)

Output contact :SPDT5A/250VAC or NPN/PNP

Induction rod material :SUS304/316

Explosion-proof class :EXDIIBT4-6

Operating temperature :-40° C -100 ° C

Operating pressure :-1-40bar

Insert length :170MM(customizable unit :mm)

YC190

Vibrating Rod Standard Type

Junction box: Aluminum alloy paint (IP65)

Installation mode: Vertical or horizontal

Voltage :22-60VDC, 22-265VAC, 50/60HZ

Power :DC-3W(MAX)AC-15W(MAX)

Connection specifications :G1-1/2 "teeth (customizable)

Output contact :SPDT5A/250VAC or NPN/PNP

Induction rod material :SUS304/316

Operating temperature :-40°C-100 °C

Operating pressure :-1-40bar

Insert length :250MM(customizable unit :mm)

Installation precautions

1. When installing, the switch can be installed horizontally at an Angle of 15°-20° to reduce the impact of materials and the occurrence of hanging phenomena.

2. The installation should be as far away from the inlet of the barrel tank as possible to avoid material impact and false alarm. If unavoidable, switch at inlet and level

Install partition plate protection between.

3. The cable inlet of the junction box must face down, and the nut fixing the cable inlet of the power cable must be locked.

4. When the staff is working in the tank, it is strictly forbidden to use the vibrator to climb or hang any rope and objects.

●

Correct installation:

a. Top mount, vibrator vertical down, can be mounted on the top (away from the feed port)

Any location.

b. Transverse installation, the vibrator tilt down 15°-20° to reduce the impact of the material

The phenomenon of hanging material occurs.

c. Transverse installation, vibrator downward tilt 15°-20°, there is a baffle above the material level switch

Length approx. 250mm, width approx. 200mm to prevent

d:

material from switching at level

Improper stacking around can reduce the impact of materials on the switch.

● Incorrect installation:

d. Installed in the discharge hopper, the maximum distance between the bottom end of the screw of the level switch and the barrel wall does not exceed (60mm)

Avoid false alarm due to improper accumulation of materials.

e. Install horizontally on the filling wall or under the feed port.

f. The installation Angle is not correct (the surface of the vibrator is prone to failure due to the high load pressure of feeding and unloading

g. If the distance between the bottom end of the screw and the barrel wall exceeds (60mm), the level switch will not work properly.

Hot Searches