- Product Details

- {{item.text}}

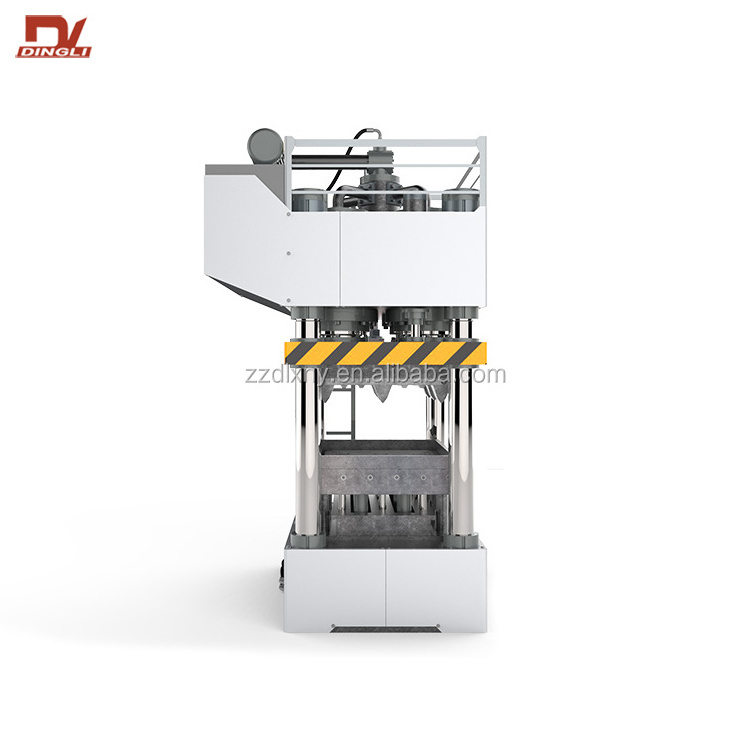

Quick Details

-

Weight (KG):

-

22000 KG

-

Power (kW):

-

18.5

-

Name:

-

Presswood Pallet Machine Compressed Wood Pallet Machine

-

Voltage:

-

380V, 50HZ, 3 phase

-

Capacity:

-

150-180pcs/day (24 hours)

-

Hydraulic cylinder diameter:

-

450mm

-

Hydraulic cylinder quantity:

-

4 pcs

-

Pressure:

-

Max 1000T (adjustable)

-

Pressing heal cycle:

-

35s

-

Shaping cycle:

-

450s

-

Dimension:

-

2000*1400*3500mm

-

Application:

-

Wood Process

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DINGLI

-

Machine Type:

-

Pallet Making Machine

-

Weight (KG):

-

22000 KG

-

Power (kW):

-

18.5

-

Name:

-

Presswood Pallet Machine Compressed Wood Pallet Machine

-

Voltage:

-

380V, 50HZ, 3 phase

-

Capacity:

-

150-180pcs/day (24 hours)

-

Hydraulic cylinder diameter:

-

450mm

-

Hydraulic cylinder quantity:

-

4 pcs

-

Pressure:

-

Max 1000T (adjustable)

-

Pressing heal cycle:

-

35s

-

Shaping cycle:

-

450s

-

Dimension:

-

2000*1400*3500mm

-

Application:

-

Wood Process

Product Introduction

Product Features

2) The size of stability, light weight, no distortion and warping.

3) The mold product size with high precision, specially designed to keep the strength of the reinforcement to ensure the product precision and production.

4)It can keep the strength and stiffness constant and removes the wood's own natural defect during moulding process,and intensity strength are more than traditional board assembly products.

5) The weight are 50% lighter than hard hard wood real wood pallet products.

6)The rounded corners design in order to prevent damaged in the process of product packaging and transportation.it can realize automatic binding processing, save operating time.

7) Can be superposition of multiple pallets piled up together, 50 pcs of pallet about 7 feet hight.a forklift truck can will tray scooping up from each side.

8) To meet the transportation of import and export business, without fumigation processing.

9) Can use wood processing residue and waste wood to make pallet.

10) products are environmentally friendly,which can realize the recycle, recycle and reuse, low pollution, recovery rate can reach 100%.

11)The price are cheaper than the traditional softwood and hardwood materials .

12) Using environment-friendly and urea-formaldehyde resin adhesive as adhesive to wood or wood fiber mould pressing directly.

13) For each standard container can put 1000 pallet, users to minimize the transportation cost.

14)The dynamic load is 1500 kg, static load is 5000 kg.

15) The same number of pallet, which can save 3/4 space than ordinary wooden pallet.a forklift truck can carry 60 pallet, and ordinary wooden pallets can only carry 18 to 20 pcs for 1 time.

|

Model

|

PM-1000

|

|

Voltage

|

380V, 50HZ, 3 phase

|

|

Capacity

|

150-180pcs/day (24 hours)

|

|

Power

|

18.5kw

|

|

Hydraulic cylinder diameter

|

450mm

|

|

Hydraulic cylinder quantity

|

4 pcs

|

|

Pressure

|

Max 1000T (adjustable)

|

|

Pressing heal cycle

|

35s

|

|

Shaping cycle

|

450s

|

|

Weight

|

22T

|

|

Dimension

|

2000*1400*3500mm

|

Below is Processing Process

Preparation of raw materials: According to the requirements of the pallet load-bearing choose wood or straw varieties, chipped into 1-2mm toothpick-like sawdust, strictly control the bark of the impurity content of not more than 5%, after magnetic separation into the dryer, raw materials after drying moisture content ≤ 5%.

Mixing: In order to prevent wood chips broken, we should not use high-speed mixing machine, the general use of roller mixing machine, set two spray system, in order to add the two should not be mixed together. Generally use is ocyanate and urea-formaldehyde resin mixture, or phenolic resin and melamine resin, the amount of sizing is 3% -8%. After the measurement of wood chips and quantitative adhesive at the same time into the mixing machine, mixed with wood moisture content, should be controlled in the range of 6-8%.

Pavement and hot pressing: adopts special equipment, pavement two times, the first for pallet and preload, and then do the plane part of the pallet. Punches fixed in the upper part of the hot press on the activities of the beam, the die is between the hot press and paving machine, placed on the lower press table, a special stripping device. Will be mixed with wood chips in the mold, the pre-pressure, hot pressed until the resin can be fully cured after the mold. First sintered wood chips, quantitative paving into the metal mold in the cold pressing preforming. And then placed in a hot press in the press molding.

The side trimming: mainly for the side cutting, that is, to remove the edge of the product surplus flash.

Below is Working Principle

The crushed wood chips or straw were dried at 300-450 ℃ for 3 min, the heat treatment time was 30min, the water in the material was removed, then mixed with the thermosetting resin, and molded at 220 ℃. The pressure was 1400psi or 98kg / cm3. In this process, the internal temperature of the pallet reaches 105 ° C and the internal temperature of the pallet is maintained above 56 ° C for more than 30 minutes and the final moisture content of the product is not more than 9%.

The entire production process is carried out at high temperatures and pressures, killing any insects and microorganisms that remain in the material, and at the same time preventing the re-intrusion and propagation of any other insects due to the high density of the wood pallets produced. This kind of molded product is the latest "artificial wood packaging material" rather than the traditional "solid wood packaging materials", its products no longer need to pest control, the product does not have any live insects and microorganisms, in line with ISPM15 (International Standard for Phytosanitary Measures 15 ) requirements for Wood Packaging Products.

Product Unique Advantages

1. Abandon the assembled framework hydraulic old traditional press machine, because for a long term using, the problems of guide instability in process of pressing, inaccurate pressing of the upper mold and lower mold and deformation of framework, come out with the framework press machine in long-term high pressure and high temperature.

2. We adopt the 3 beam Four-Column Guide Device structure, which solved the problems of guide instability and the deformation of framework.

3. We adopt the design of crossbeam, which solved the problem of press inaccuracy of the upper and lower mold.

4. With Pallet Machinery's new technology, problems of the edge burrs has been completely solved. Workers operate grinders to remove burrs, which has become history.

Below is Dingli Group Packaging & Shipping:

Your device will be packed well in container and suit for long ocean shipping.

Below is Dingli Group Service Items:

Pre-sale

1. According to your needs, select right model for you.

2. According to your special requirements, design customized solution and manufacture customized products for you.

3. Welcome your visit.

Sale

1. Sign contract, pay deposit, we arrange production.

2. Product acceptance.

3. Help you formulate construction scheme.

After-sale

1. Assign engineer service for you on-site freely.

2. Install and adjust device, train how to operate.

3. After installation, leaving 1-2 technical staff to help you on-site production, until achieve customer satisfaction.