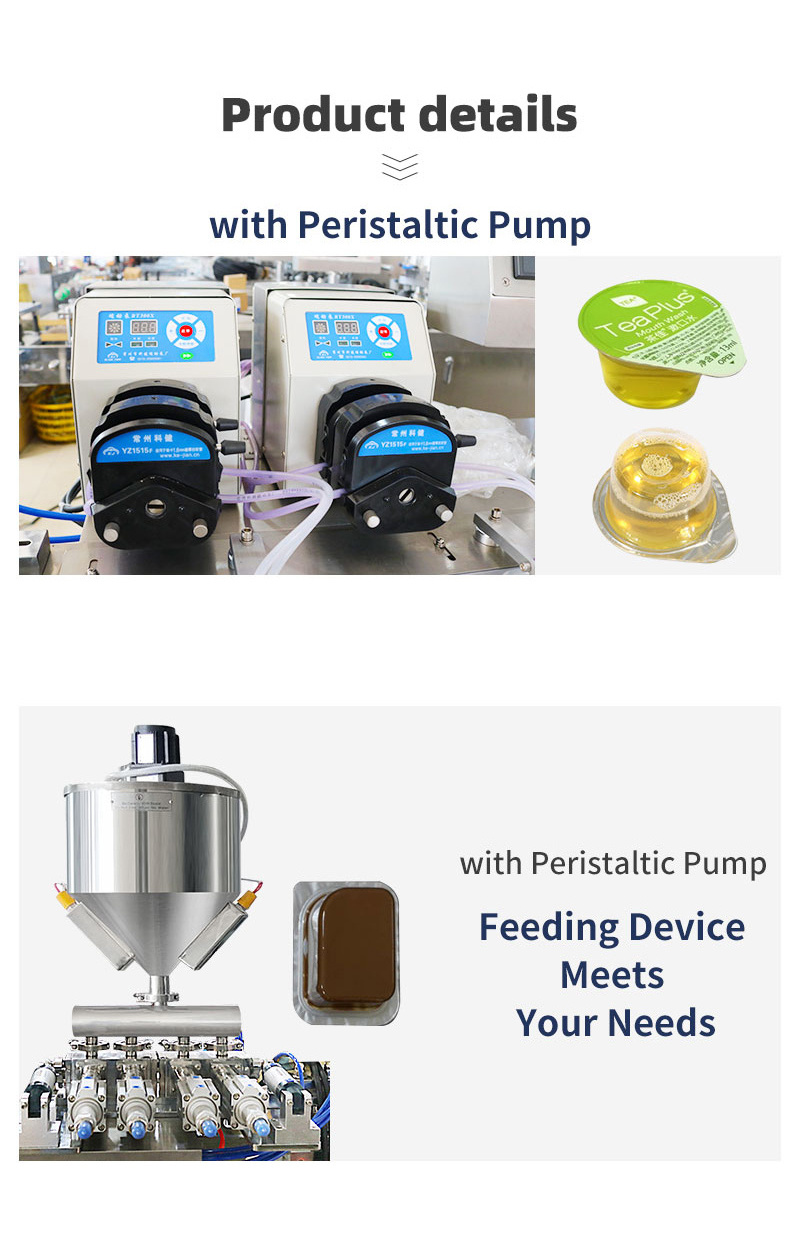

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1450*550*1100mm

-

Weight:

-

465 KG

-

Model:

-

DPB-80

-

Speed:

-

900-2400blisters/hour

-

Max forming area:

-

80x105X25(mm)

-

Air pressure:

-

0.4-0.6Mpa

-

Total power:

-

220V 50Hz 2.4Kw

-

Main electrical power:

-

0.75kw

-

PVC rigid film:

-

0.15-0.4x110mm

-

Aluminum foil:

-

0.02-0.04x110mm

-

Dialysis paper:

-

50-100gx110mm

-

Product Name:

-

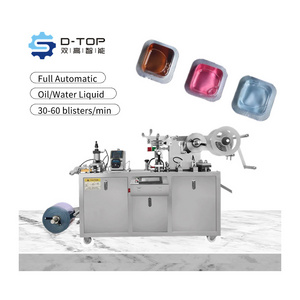

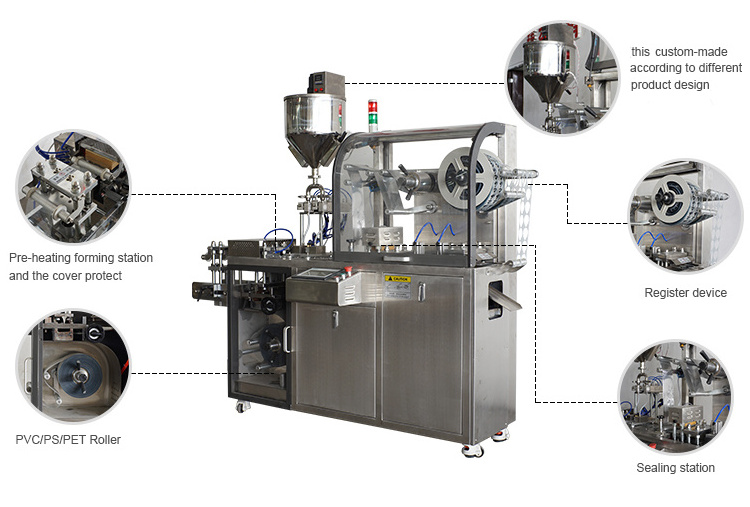

Automatic Blister Packing Machine

Quick Details

-

Voltage:

-

220V 50Hz

-

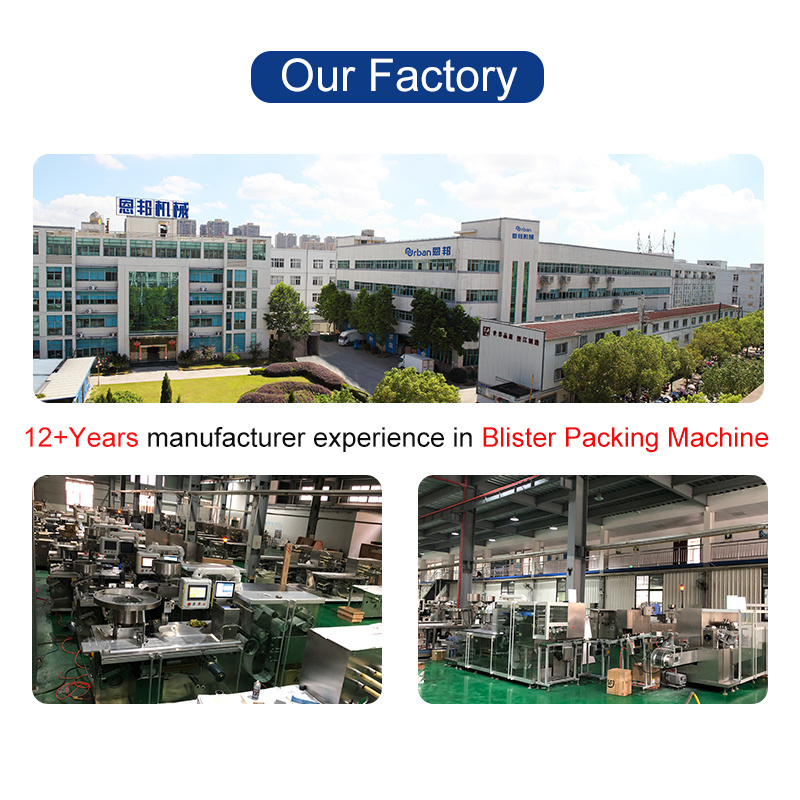

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Urban

-

Dimension(L*W*H):

-

1450*550*1100mm

-

Weight:

-

465 KG

-

Model:

-

DPB-80

-

Speed:

-

900-2400blisters/hour

-

Max forming area:

-

80x105X25(mm)

-

Air pressure:

-

0.4-0.6Mpa

-

Total power:

-

220V 50Hz 2.4Kw

-

Main electrical power:

-

0.75kw

-

PVC rigid film:

-

0.15-0.4x110mm

-

Aluminum foil:

-

0.02-0.04x110mm

-

Dialysis paper:

-

50-100gx110mm

-

Product Name:

-

Automatic Blister Packing Machine

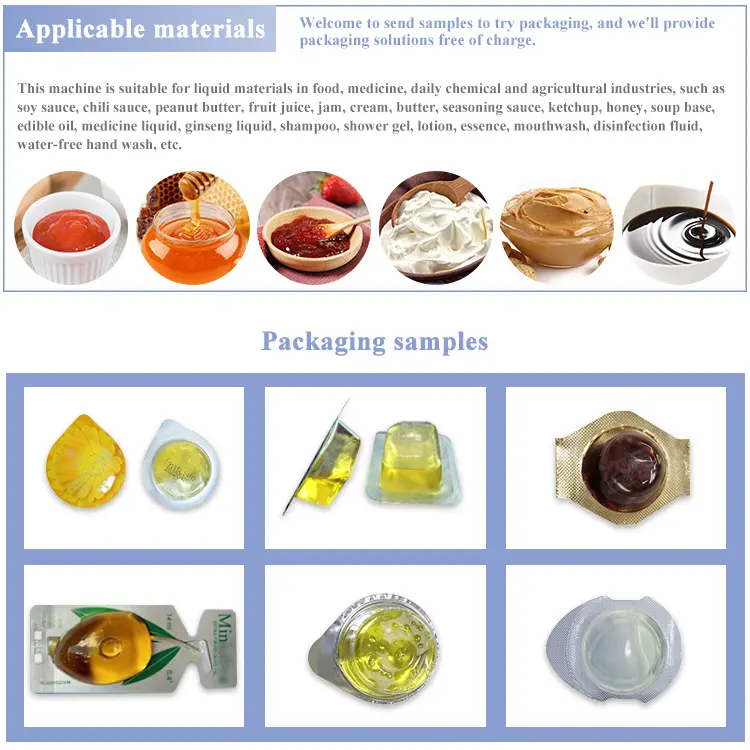

Products Description

Solid blister machine

Application: toothbrush/perfume/car liquid perfume/car air freshener/

Liquid blister machine

Application:liquid/chocolate/butter/jam/honey/paste/sauce/ketchup blister packing machine,etc.

|

Model

|

DPB-80

|

DPB-110

|

DPB120

|

DPB150

|

|

Punch frequency

|

10-33times/min

|

10-33tims/min

|

10-33times/min

|

10-35times/min

|

|

Production capacity

|

1980plates/hour

|

1980plates/hour

|

2400plates/hour

|

4200plates/hour

|

|

Max. Forming area & Depth

|

105x70(standard depth <15mm)

|

115x90(standard depth <15mm)

|

125x70(standard depth <15mm)

|

145xll0(standard depth <15mm)

|

|

|

Max. Depth 25mm

|

Max. depth 26mm

|

Max. Depth 25mm

|

Max. depth 26mm

|

|

Standard Stroke range

|

30-80mm

|

35-90mm

|

30-80mm

|

50-120mm

|

|

Standard plate size

|

80x57mm

|

80x57mm

|

80x57mm

|

80x57mm

|

|

Air pressure

|

0.4-0.6Mpa

|

0.4-0.6Mpa

|

0.4-0.6Mpa

|

0.4-0.6Mpa

|

|

Compressed air required

|

Air compressor>0.3m3/min

|

Air compressor>0.3m3/min

|

Air compressor>0.3m3/min

|

Air compressor>0.3m3/min

|

|

Total power supply

|

220V 50Hz 2.4Kw

|

220V 50Hz 2.4Kw

|

220V 50Hz 2.4Kw

|

220V 50Hz 2.4Kw

|

|

Main motor

|

0.75Kw

|

0.75Kw

|

0.75Kw

|

1.5KW

|

|

PVC hard Film

|

0.15-0.5xll0mm

|

0.15-0.5X HOmm

|

0.15-0.5 x 130mm

|

0.15-0.5x 160mm

|

|

PTP Aluminum film

|

0.02-0.035 x HOmm

|

0.02-0.035 x HOmm

|

0.02-0.035 x 130mm

|

0.02-0.035 x 160mm

|

|

Mould cooling

|

Tap water or Recycling water

|

Tap water or recycling water

|

Tap water or Recycling water

|

Tap water or recycling water

|

|

Overall Dimension(LxWxH)

|

1450x590x 1100mm

|

1600 x 620 x1420mm

|

1870x610x1100mm

|

2315 x 635 x 1405mm

|

|

Weight

|

465kg

|

485kg

|

660kg

|

890KG

|

|

Noise

|

<75dBA

|

<75dBA

|

<75dBA

|

<75dBA

|

It adopts the newest type high-power transmission mechanism to arrange the chain and drive the main driving shaft. The errors and noises of other gear wheel transmission can be avoided.

Imported controlling system is adopted; also it can be equipped with detecting and rejection function device for number

according to the user’s requirement.

It adopts photo electrical controlling system to make PVC, PTP, Aluminum/Aluminum material to be automatically fed and waste side to be cut automatically to guarantee the Synchronous stability of over- length distance and multi stations.

It can be optional equipped with photocell correction device, imported stepper motor traction and image- character register to optimize packing grade.

Imported controlling system is adopted; also it can be equipped with detecting and rejection function device for number

according to the user’s requirement.

It adopts photo electrical controlling system to make PVC, PTP, Aluminum/Aluminum material to be automatically fed and waste side to be cut automatically to guarantee the Synchronous stability of over- length distance and multi stations.

It can be optional equipped with photocell correction device, imported stepper motor traction and image- character register to optimize packing grade.

Hot Searches