- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

BMS

-

Voltage:

-

380V/50HZ 3Phase(as Customer's Request)

-

Power:

-

5.5KW+2.2KW

-

Dimension(L*W*H):

-

85000*1500*1200

-

Weight:

-

8.5 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Working material:

-

galvanized sheet(GI),cold roll steel(CRC)

-

Thickness:

-

0.45-0.65mm

-

Yield strength:

-

245-550Mpa

-

Decoiler:

-

Manual/Hydraulic for options

-

Housing:

-

H350 beam

-

Side wall thickness:

-

20mm

-

Shaft:

-

75mm/85mm

-

Forming station:

-

18 steps

-

Cutter material:

-

Cr12Mov, Heatment

Quick Details

-

Work Pressure:

-

245---550Mpa

-

Production Capacity:

-

12-18m/min

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

BMS

-

Voltage:

-

380V/50HZ 3Phase(as Customer's Request)

-

Power:

-

5.5KW+2.2KW

-

Dimension(L*W*H):

-

85000*1500*1200

-

Weight:

-

8.5 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Working material:

-

galvanized sheet(GI),cold roll steel(CRC)

-

Thickness:

-

0.45-0.65mm

-

Yield strength:

-

245-550Mpa

-

Decoiler:

-

Manual/Hydraulic for options

-

Housing:

-

H350 beam

-

Side wall thickness:

-

20mm

-

Shaft:

-

75mm/85mm

-

Forming station:

-

18 steps

-

Cutter material:

-

Cr12Mov, Heatment

Product Description

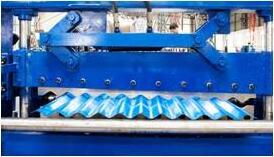

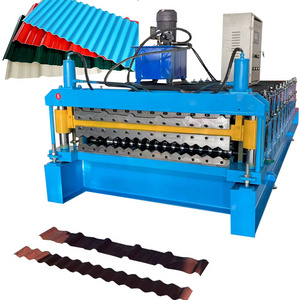

Used Metal Corrugated Panel Roll Forming Machine for Building Material

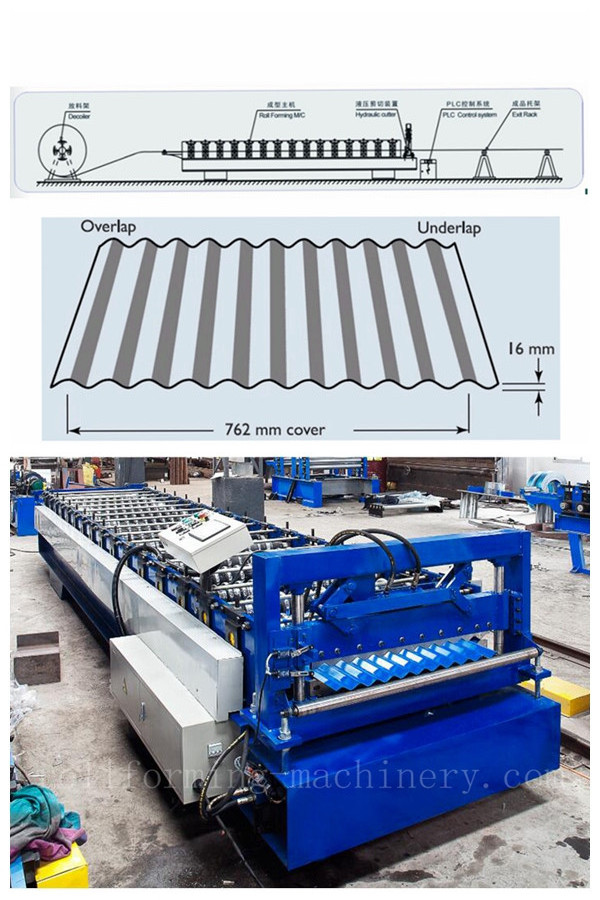

1. Details of corrugated panel roll forming machine

| Material |

| Material Thickness(&):0.45-0.65mm |

| Applicable material:Galvanized Steel Coils,Cold Rolled Coils,yield strength 245Mpa or 550Mpa |

| Machine Components |

| 1)Manual Decoiler: one set |

| Max. feeding width: 500mm, coil ID range 470mm±30mm |

|

Capacity: Max. 3Ton

|

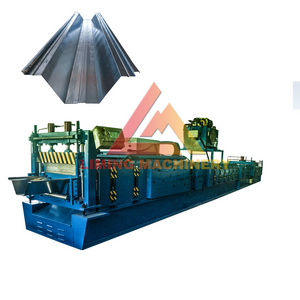

| 2) Cold Rolling Mills: |

|

Rollers manufactured from bearing steel GCr15,precision machined,hard Chrome Coated with thickness 0.04mm(for longer life and anti-rust) ;

|

|

Motor Driving,Gear chain transmission,18 forming stations and 7 rollers(3 upper rollers and 4down rollers)for straightening and levelling) |

| Main Motor=5.5KW , Frequency speed control |

| Forming speed approx.12-15m/min |

| 3)Hydraulic Cutting device |

| hydraulic motor: 2.2KW, Hydraulic pressure range: 0-16Mpa |

| Cutting tool material: Cr12, Heat treatment |

| 4)PLC Control System (Touch screen brand:Taiwan WEINVIEW,Inverter brand:Finland VOCAN/Denmark Danfoss ,Encoder brand: Japan Koyo) |

| Control the quantity and cutting length automatically |

| Combined with: PLC, Inverter, Touch Screen, Encoder, etc |

| Cut-to-length tolerance≤±1mm |

| Control Voltage 24V |

5) Exit Rack Un-powered, two units

|

2. Machine Features of corrugated panel roll forming machine

The advantages of corrugated roof panel roll forming machine are as follows:

1.Easy operation, low maintenance cost

2.Material saving

3.Type of penel is wide used.

3. Detailed Images of corrugated panel roll forming machine

Machine Parts

Name:

Corrugated roof panel roll forming machine feeding device

Brand: BMS

Original: China

make the steel materials move more smoothly

Machine Parts

Name:

Cutting system

Brand:

BMS

Original:

China

made by high quality model steel Cr12Mov with heat treatment

Machine Parts

Name:

Rollers

Brand:

BMS

Original:

China

Rollers manufactured from high quality bearing steel GCr15, CNC lathes, Heat Treatment.With black treatment or Hard-Chrome Coating for options.

Machine Parts

Name:

PLC control system

Brand:

SIEMENS/SCHNEIDER ELECTRIC

Original:

Germany/France

Combined with: PLC, Inverter, Touch Screen, Encoder, etc

Encoder: KOYO/Omron (Japan brand)

4. Certifications

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Profile drawing and roll forming solution.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packaging & Shipping

(1) Main body of machine: Nude packing in the container suitable for long term transportation.

(2) With even lifting point in the machine for easy container loading and uploading.

Company information

Company Show

Factory Show

BMS Machine (formerly named as HF BRAND FORMING MACHINERY CO.,LTD) was established in 1996,which covers an area of MORE THAN 20000 SQUARE METERS . With 20 YEARS PROFESSIONAL EXPERIENCE , we have been the TOP 3 manufacturer and exporter of cold roll forming machines in China. We are an ISO9001 approved company , and have European CE certification (issued by SGS) . We have the honor to serve some of the famous companies in the world such as TATA STEEL, BLUESCOPESTEEL, BRADBURY MACHINERY ,etc.

We manufacture wide range products of metal sheet cold roll forming machines as follows: 1) for Metal Building Industry/PEB (Pre-Engineering Building): HAYES style quick change CZ purlin machine(including automatic and quick-change type C purlin machine and Z purlin machine), light gauge steel framing machine( LGSF, Howick and SCOTTSDALE style ), roof panel forming machine, corrugated panel roll forming machine, curving machine, glazed tile roll forming machine, floor decking machine, ridge cap roll forming machine, cladding facade system forming machine, cut-to-length slitting line etc., as well as some hydraulic shearing machine, hydraulic folding machine for gutter and flashing, etc.

Related Products

C80-300 Automatical C Shaped Steel Roll Forming Machine