- Product Details

- {{item.text}}

Quick Details

-

Max. Spindle Speed (r.p.m):

-

30 r.p.m

-

Spindle Bore(mm):

-

82 m'm

-

Width of bed (mm):

-

51 mm

-

Spindle Motor Power(kW):

-

15

-

Max. Turned Length (mm):

-

500

-

Travel (X Axis)(mm):

-

200 mm

-

Travel (Z Axis)(mm):

-

530 mm

-

Positioning Accuracy (mm):

-

0.003mm

-

Repeatability (X/Y/Z) (mm):

-

0.005mm

-

Place of Origin:

-

Guangdong, China

-

Dimension(L*W*H):

-

2500*1948*1950MM

-

Brand Name:

-

COORAY

-

Model Number:

-

COORAY-MJS500

-

Weight (KG):

-

4500

-

Marketing Type:

-

New Product 2023

-

Maximum Slewing Diameter:

-

500mm

-

Maximum machining diameter:

-

400mm

-

YS axis maximum travel:

-

±50mm

-

X/Z axis rapid traverse speed:

-

30m/min

-

Spindle speed:

-

3000r/min

-

X-axis, Z-axis, Y-axis servo motor:

-

1800W

-

Total machine power:

-

35kw

-

Product name:

-

COORAY-MJS500

-

Control system:

-

SIEMENS GSK FANUC (optional)

-

Supply Ability:

-

100 Set/Sets per Month

Quick Details

-

Type:

-

VERTICAL

-

Max. Length of Workpiece (mm):

-

500mm

-

Year:

-

2023

-

Max. Spindle Speed (r.p.m):

-

30 r.p.m

-

Spindle Bore(mm):

-

82 m'm

-

Width of bed (mm):

-

51 mm

-

Spindle Motor Power(kW):

-

15

-

Max. Turned Length (mm):

-

500

-

Travel (X Axis)(mm):

-

200 mm

-

Travel (Z Axis)(mm):

-

530 mm

-

Positioning Accuracy (mm):

-

0.003mm

-

Repeatability (X/Y/Z) (mm):

-

0.005mm

-

Place of Origin:

-

Guangdong, China

-

Dimension(L*W*H):

-

2500*1948*1950MM

-

Brand Name:

-

COORAY

-

Model Number:

-

COORAY-MJS500

-

Weight (KG):

-

4500

-

Marketing Type:

-

New Product 2023

-

Maximum Slewing Diameter:

-

500mm

-

Maximum machining diameter:

-

400mm

-

YS axis maximum travel:

-

±50mm

-

X/Z axis rapid traverse speed:

-

30m/min

-

Spindle speed:

-

3000r/min

-

X-axis, Z-axis, Y-axis servo motor:

-

1800W

-

Total machine power:

-

35kw

-

Product name:

-

COORAY-MJS500

-

Control system:

-

SIEMENS GSK FANUC (optional)

-

Supply Ability:

-

100 Set/Sets per Month

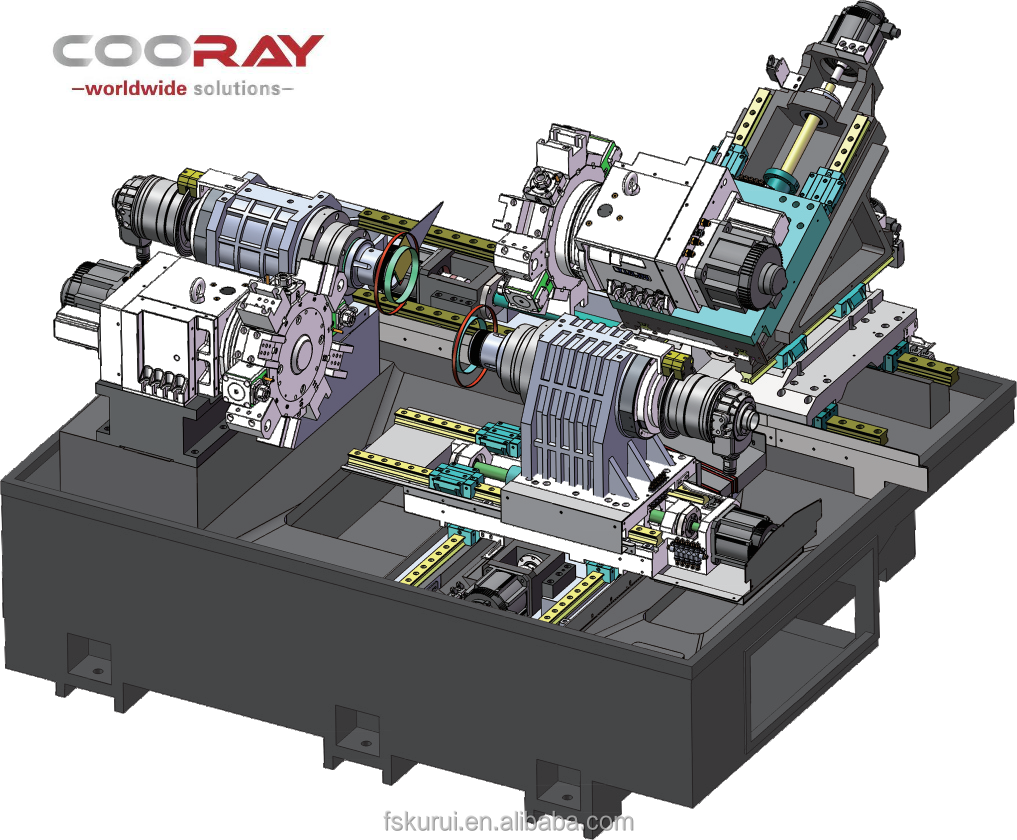

Products Description

|

Model

|

Unit

|

MJS500

|

|

Numerical Control System

|

New Generation or Fanuc

|

220TB Oi-TF PLUS

|

|

Maximum bar diameter of spindle

|

mm

|

51

|

|

Sub-spindle maximum bar diameter

|

mm

|

45

|

|

Maximum Slewing Diameter

|

mm

|

500

|

|

Maximum processing length

|

mm

|

500

|

|

Maximum machining diameter

|

mm

|

400

|

|

Maximum X-axis travel

|

mm

|

200

|

|

Maximum Z-axis travel

|

mm

|

530

|

|

YS axis maximum travel

|

mm

|

±50

|

|

X/Z axis rapid traverse speed

|

m/min

|

30

|

|

Motor Repeat Positioning Accuracy

|

mm

|

0.005

|

|

Motor spindle power

|

kw

|

15

|

|

Motor spindle speed

|

r/min

|

3000

|

|

X-axis, Z-axis, Y-axis servo motor

|

w

|

1800

|

|

Number of turret tools

|

|

12

|

|

Total machine power

|

kw

|

35

|

|

machine size

|

mm

|

2500*1948*1950

|

|

machine weight

|

kg

|

4500

|

Dual spindle with Y-axis turret for carving, milling, drilling and tapping of workpieces.

●

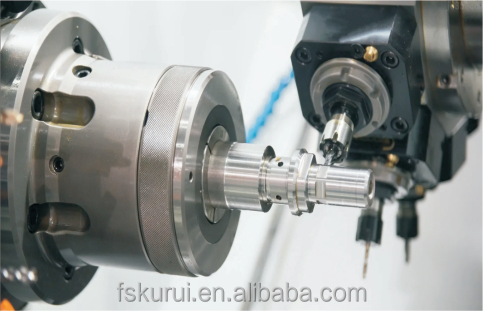

Dual spindle single turret design, a clamping to complete the product turning, milling, drilling, tapping and other complex processing, using the German Xiaotte 12-station BMT55 servo-powered turret, fast tool change, tool change repeatability 0.003mm, high power, strong rigidity, 12-station can be installed 90°/0° power head.Fast tool change, tool change repeatability 0.003mm, milling power, strong rigidity, 12 stations can be installed 90 ° / 0 ° power head.

●

The main spindle adopts 15KW built-in electric spindle and the sub-spindle adopts 11KW built-in electric spindle, which has fast response speed, reduces vibration and thermal deformation under high speed operation, ensures high rigidity and stability of the main spindle, and the spindle runout ﹤2um meets the demands of various machining, and is suitable for machining fields with high precision and high surface quality requirements. Dual-channel work, main spindle and sub-spindle can be processed independently at the same time, shortening the total processing time.

●

X/Y/Z axis motor power 1.8KW servo motor.

●All axes adopt high precision double preloaded ball screws to ensure positioning and repeatability.

●Screw 40/32mm large lead 12/10mm pitch, guideway 45/35 roller guideway.

●The machine body, motor frame, bearing seat, X-axis drag plate all adopt one-piece structure to ensure the precision of mechanical structure and enhance the rigidity.

●

The interpolation Y-axis mechanical structure, so that the centre of gravity of the turret is always within the range of the saddle slide, so that the machine tool milling rigidity has been greatly strengthened, the Y-axis stroke is long (± 50mm) can be processed complex parts, even in the compact layout of the machine tool space, but also can be machined in large diameters.

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What's your main products of your company?

A: We specialized in all kinds of machines ,such as CNC Lathe Machine ,CNC Milling Machine ,Vertical Machining Center ,Lathe Machines ,Drilling Machine ,Radial Drilling Machine ,Sawing Machine ,Shaper machine,gear hobbing machine and so on .

3: Where is our factory located? How can I visit there?

A : Our factory is located in Foshan City ,Guangdong Province,528300 China. You are warmly welcomed to visit us.

4. What is your trade terms?

A : FOB, CFR and CIF all acceptable.

5: What's the Payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ; Irrevocable LC at sight

6: What's the MOQ?

A: 1 set .(Only some low cost machines will be more than 1 set )

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Hot Searches