——

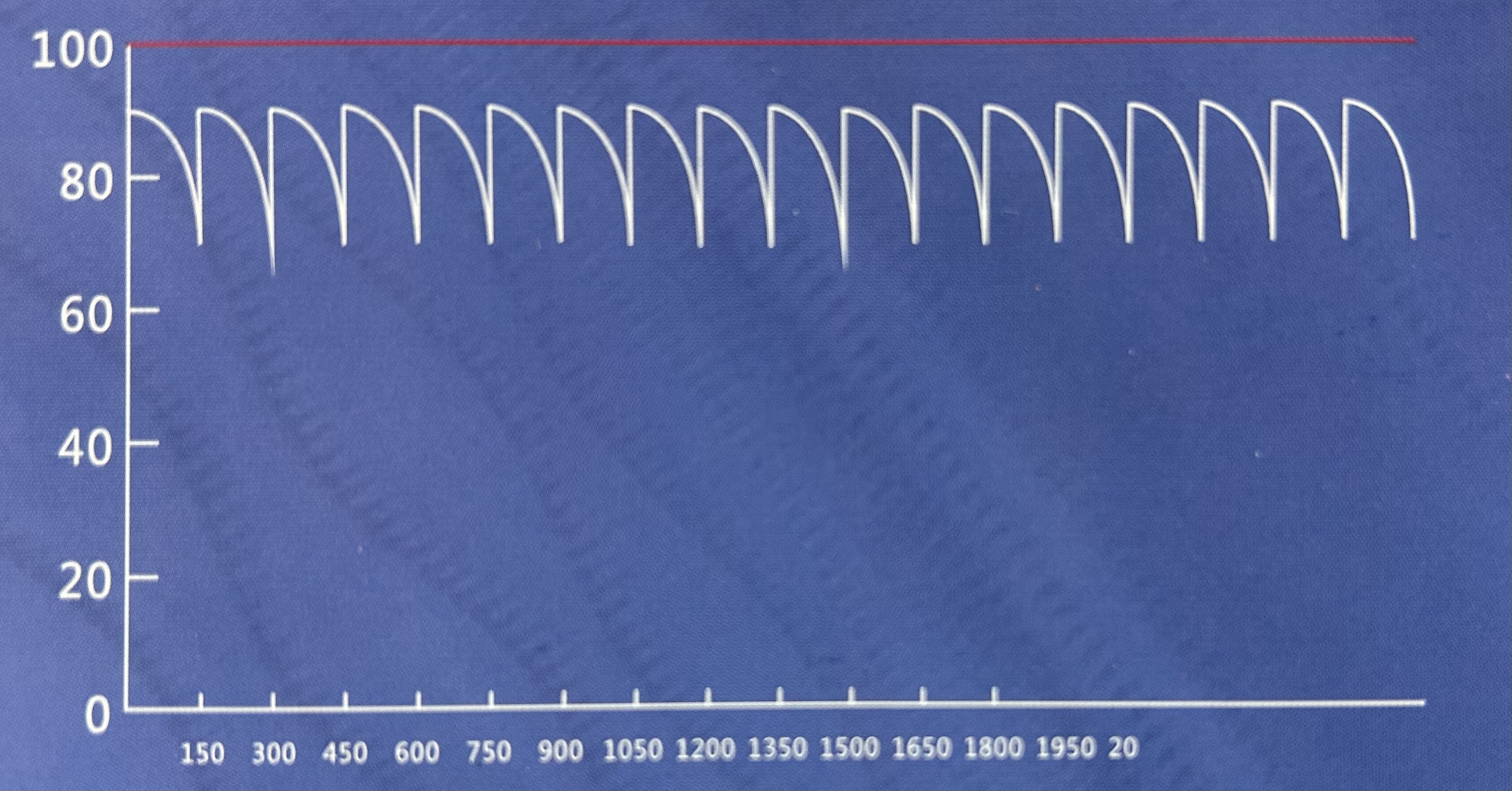

The plant needle roller maintains high efficiency throughout the life cycle

——The efficiency of needle roller decreases quickly and must be replaced to maintain high efficiency

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Decho

-

Color:

-

Gold

-

Texture:

-

Aluminium alloy

-

Product name:

-

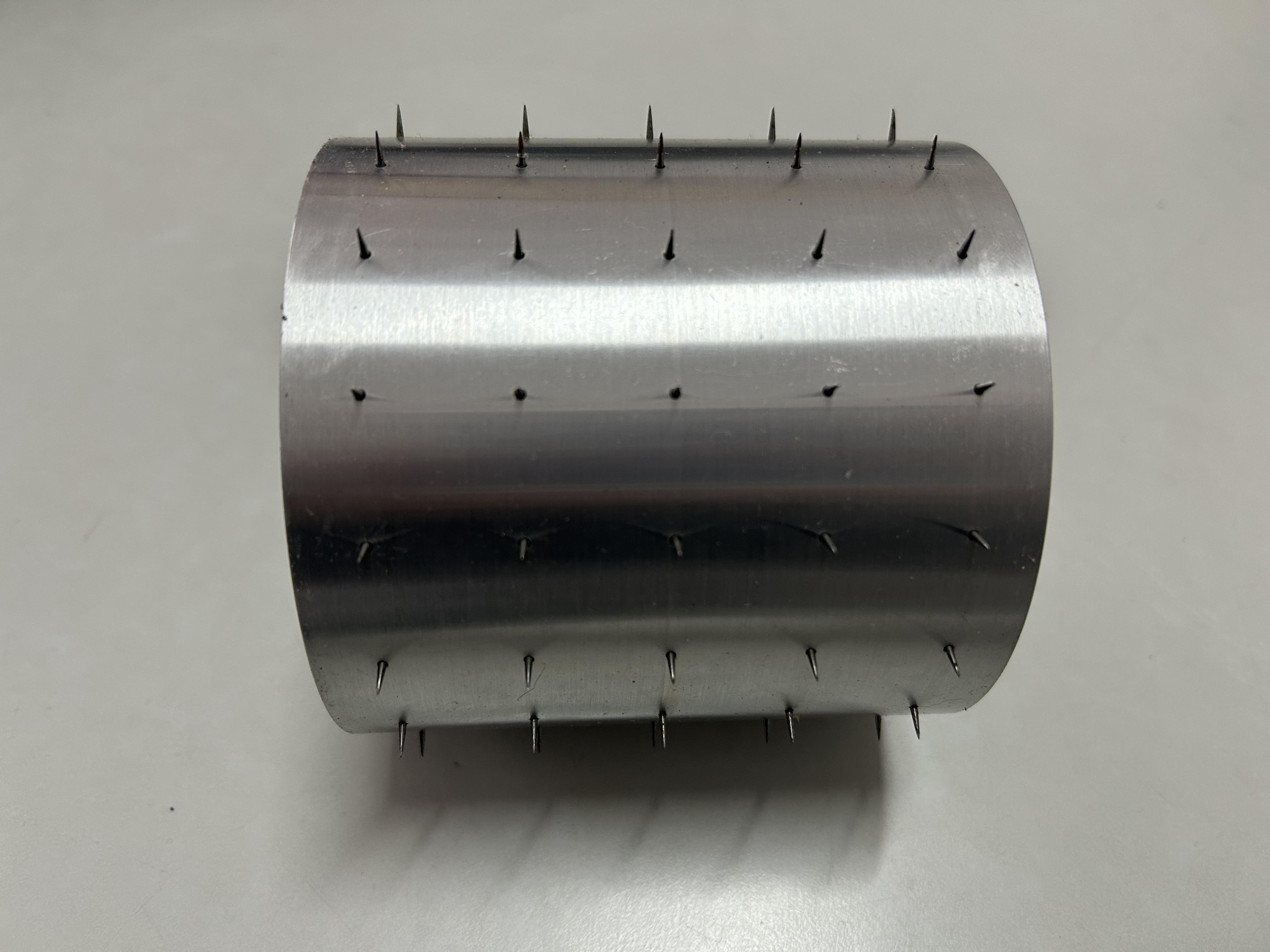

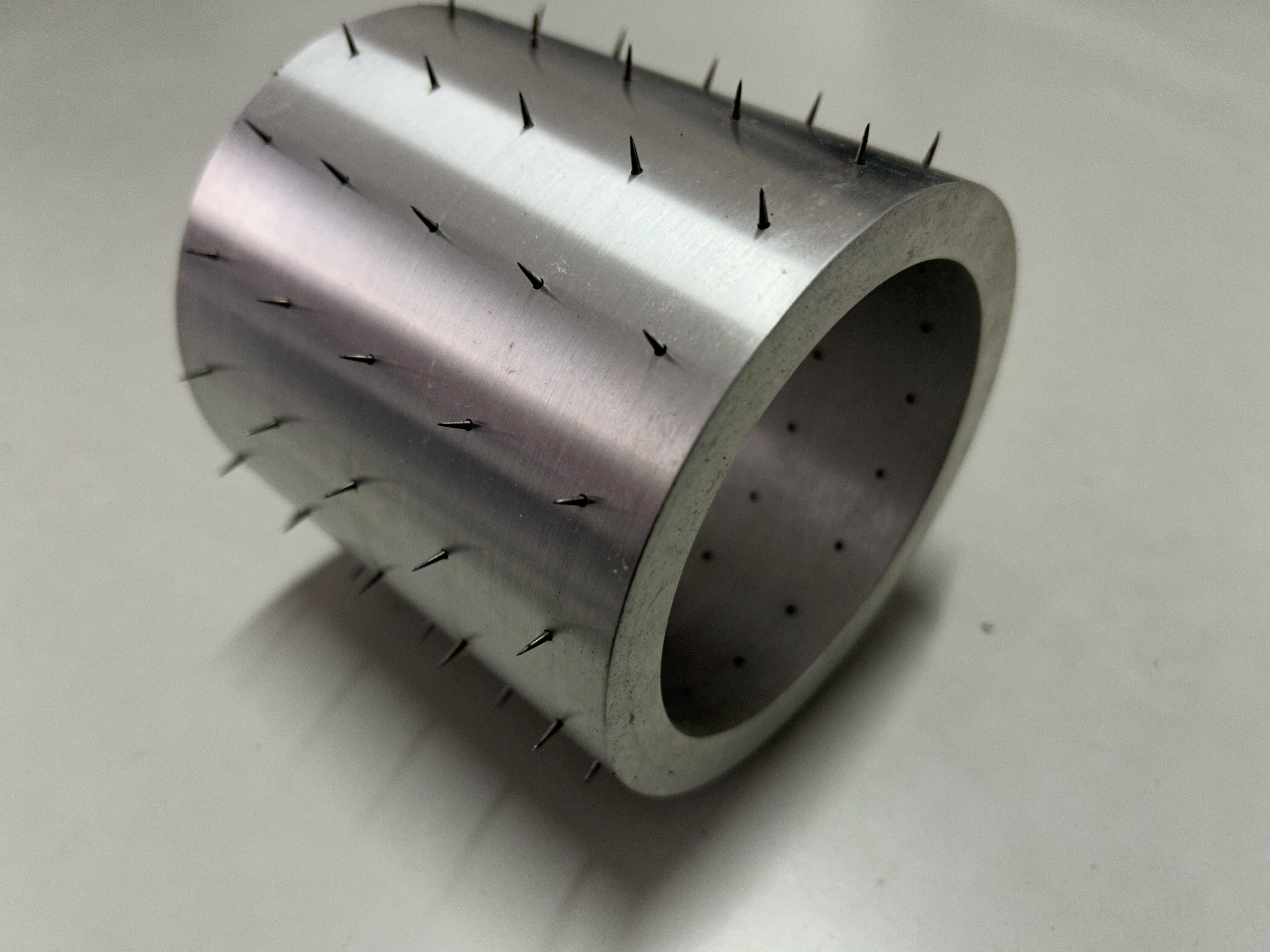

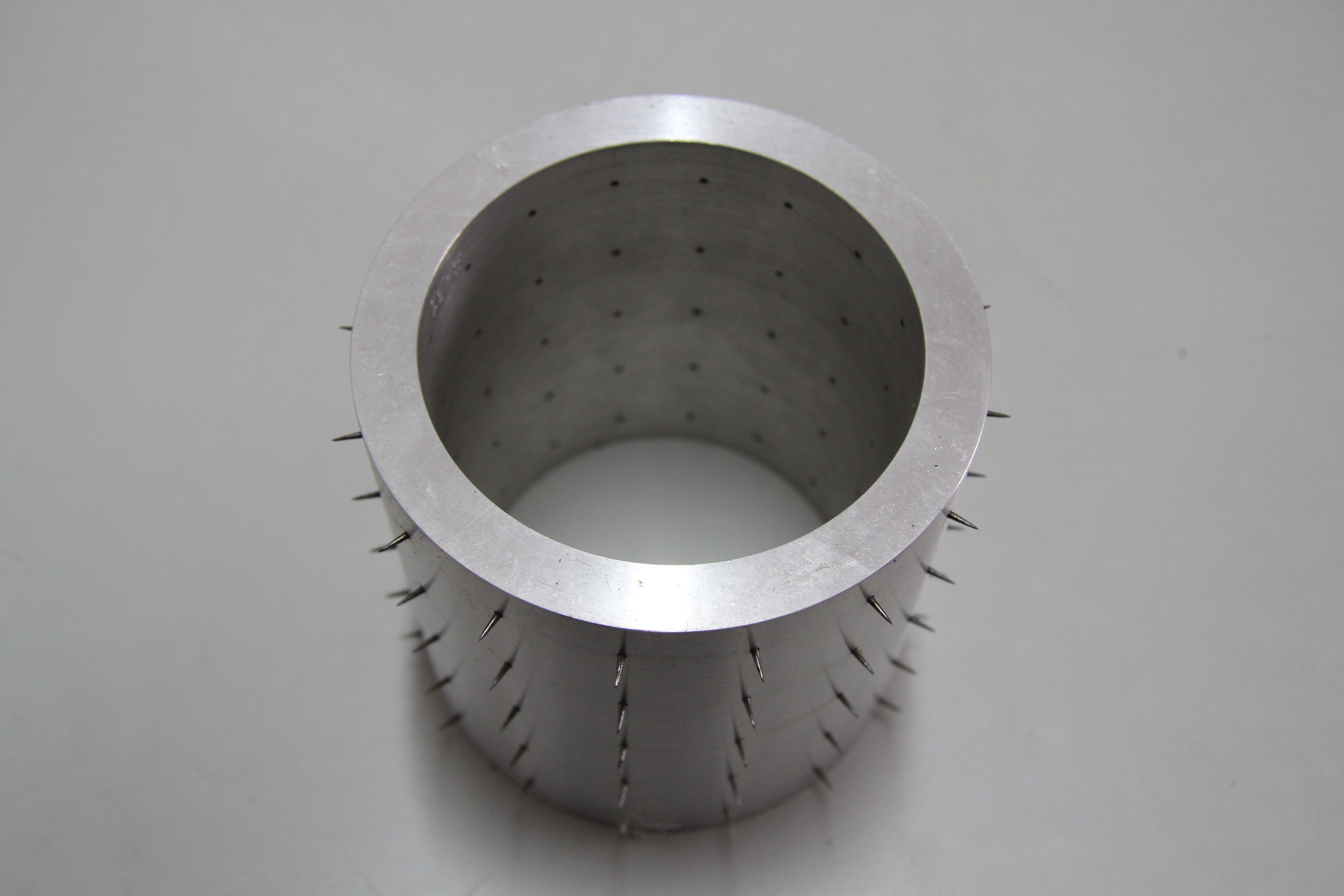

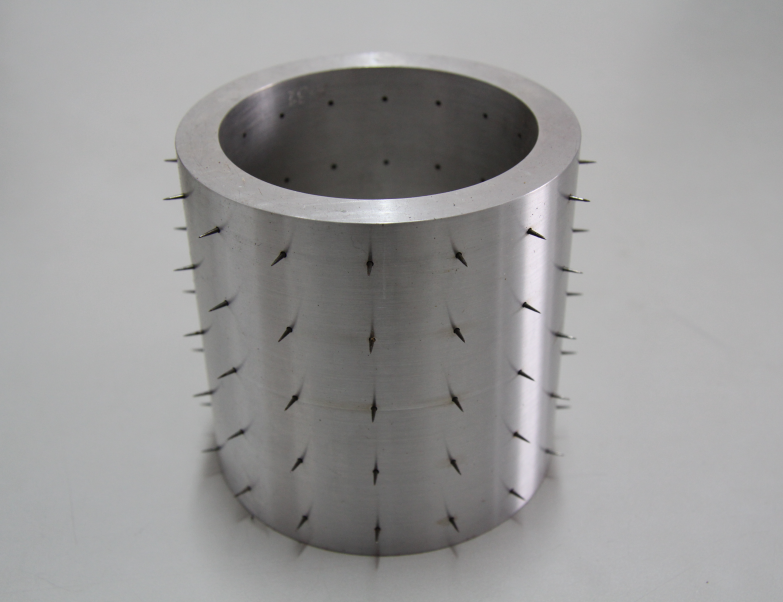

Piercing Mechanical Needle Loop

-

Package:

-

Wooden box

Quick Details

-

Use:

-

Textile Dyeing Machinery

-

Type:

-

Piercing Mechanical Needle Loop

-

Weight (KG):

-

1

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Decho

-

Color:

-

Gold

-

Texture:

-

Aluminium alloy

-

Product name:

-

Piercing Mechanical Needle Loop

-

Package:

-

Wooden box

Product Overview

Factory direct operation pinned perforation rollers&units pinpoint quality technology accuracy customization

DECHO is the world's leading manufacturer of needle nail products.

The nail piercing products produced by DECHO are precise, strong and durable, and will be easily installed on the customer's existing production line.

PRODUCT SPECIFICATIONS

The experiment shows that the use of needle - planting roller can effectively reduce the short melting of cotton knots

The smooth tip effectively protects the fibers from damage

The sharp edges of a serrated stitch tend to damage the fibers

Efficiency comparison between needle-implanted licker-in and clothing-type licker-in

* Fiber production (ton)

DECHO has more than 135 years of experience in the research and development of nail products in many fields, and now it has developed into a supplier of original parts for many world equipment manufacturers, and its products are exported to more than 50 countries. Wide range of applications, can be applied in both Tottenham and Tottenham.

|

Part Name

|

Item No.

|

Custom processing

|

Color

|

Material

|

Function

|

Type

|

Size

|

Inside diameter

|

Outer diameter

|

|

Cotton licker-in

|

RTC0258

|

Yes

To map processing

Sample processing

|

Silver

|

Aluminum alloy

|

Textile

|

Loom accessories

|

1495

|

|

253

|

|

Piercing Mechanical Needle Loop

|

CPC5800

|

Yes

To map processing

Sample processing

|

Silver

|

Aluminum alloy

|

Textile accessories

|

Loom accessories

|

100

|

79

|

110

|

|

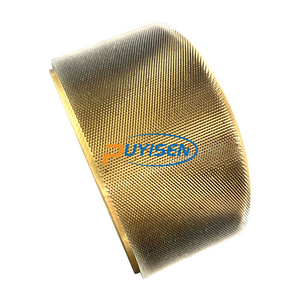

Opening pin ring

|

TMC0155

|

Yes

To map processing

Sample processing

|

Metallic color

|

Copper alloy

|

Textile accessories

|

Loom accessories

|

48

|

80

|

120

|

|

Needle pierced ring

|

CPC5801

|

Yes

To map processing

Sample processing

|

Metallic color

|

Aluminum alloy

|

Textile

|

Loom accessories

|

40

|

39

|

54

|

|

Needle ring

|

KSC1401

|

Yes

To map processing

Sample processing

|

White

|

Nylon

|

Textile

|

Loom accessories

|

40

|

72

|

101.8

|

|

Curling machine tine roller

|

DSC1562

|

Yes

To map processing

Sample processing

|

Metallic color

|

Copper alloy

|

Textile accessories

|

Loom accessories

|

73

|

12

|

24.2

|

|

Curling machine tine roller

|

DSC5802

|

Yes

To map processing

Sample processing

|

Metallic color

|

Copper alloy

|

Textile accessories

|

Loom accessories

|

73

|

12

|

24.2

|

|

Spiked roller

|

BHC1901

|

Yes

To map processing

Sample processing

|

Metallic color

|

Copper alloy

|

Textile

|

Loom accessories

|

100

|

25

|

82

|

|

Needle roller

|

BGC5803

|

Yes

To map processing

Sample processing

|

Metallic color

|

Copper alloy

|

Textile

|

Loom accessories

|

60

|

50

|

108

|

|

Carding roller

|

SSC0992

|

Yes

To map processing

Sample processing

|

Silver

|

Aluminum alloy

|

Textile accessories

|

Loom accessories

|

32.9

|

33.5

|

80

|

|

Needle block

|

POC2103

|

Yes

To map processing

Sample processing

|

Metallic color

|

Aluminum alloy

|

Textile accessories

|

Loom accessories

|

46

|

|

|

|

Needle ring

|

PVC1737

|

Yes

To map processing

Sample processing

|

Metallic color

|

Aluminum alloy

|

Textile

|

Loom accessories

|

8

|

26

|

50.4

|

|

Perforating roller

|

BGC2009

|

Yes

To map processing

Sample processing

|

Metallic color

|

Copper alloy

|

Textile

|

Loom accessories

|

95

|

76

|

105

|

|

Needle strip

|

FBC1459-01

|

Yes

To map processing

Sample processing

|

Metallic color

|

Copper alloy

|

Textile accessories

|

Loom accessories

|

700

|

|

|

|

Stenter needle plate

|

STC2066

|

Yes

To map processing

Sample processing

|

Metallic color

|

Copper alloy

|

Textile accessories

|

Loom accessories

|

125

|

|

|

Detail Images

Design

We have a lot of standard design parts, also can be customized according to customers including needle plate and needle roller.

Long life steel needle

High quality carbon steel and stainless steel needles are used in our products to ensure long life and clean and smooth puncture.

Precision

The uniform concentricity and arrangement of steel needles ensure that customers can control the size of the piercing hole by controlling the penetration depth of steel needles.

DECHO micropuncture has a wide range of applications, including laminated paper bags and cement bags, food packaging, films, laminates, cardboard, leather, metal foil, sound and vapor barriers, hygiene products, medical applications, temperature control, etc.

Cold puncture

The bearing seat is used to fix it, which is conducive to the rapid insertion of the needle roller and the precise positioning of the original set position.

The supporting rollers below will be made of different materials according to the different materials processed by customers.

The lighter weight of the licker-in roll reduces bearing load and power consumption DECHO cold licker-in rolls can reach a maximum width of 2500mm at present

Hot puncture

DECHO will choose different materials for processing according to the needs of different customers and different needle densities. Everything is just tailored for you.

Flexibility

DECHO needle rollers can be processed into any length and Finally, it is assembled into a whole roller, which is convenient for later maintenance and replacement.

SALES AND SERVICE NETWORK

Successful Project

Project in Thailand

Project in India

Project in Russia

ABOUT US

FAQ

1. who are we?

We are based in Henan, China, sell to Southeast Asia(25.00%),North America(15.00%),Domestic Market(10.00%),Eastern

Europe(10.00%),Central America(6.00%),Northern Europe(5.00%),South America(5.00%),Western Europe(5.00%),Southern

Europe(5.00%),South Asia(5.00%),Oceania(5.00%),Eastern Asia(2.00%),Africa(1.00%),Mid East(1.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Cleaning needle roller, carding machine licker-in roller, open-end spinning carding roller, hot and cold thorn products, etc.

4. why should you buy from us not from other suppliers?

Our company has become the original parts supplier for more than 35 world-renowned equipment manufacturers, and our products have been sold in more than 50 countries.

We are the world leader in pin products, offering higher precision, strength and durability than conventional products.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,Western Union;

Language Spoken:English,Chinese,Spanish

We are based in Henan, China, sell to Southeast Asia(25.00%),North America(15.00%),Domestic Market(10.00%),Eastern

Europe(10.00%),Central America(6.00%),Northern Europe(5.00%),South America(5.00%),Western Europe(5.00%),Southern

Europe(5.00%),South Asia(5.00%),Oceania(5.00%),Eastern Asia(2.00%),Africa(1.00%),Mid East(1.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Cleaning needle roller, carding machine licker-in roller, open-end spinning carding roller, hot and cold thorn products, etc.

4. why should you buy from us not from other suppliers?

Our company has become the original parts supplier for more than 35 world-renowned equipment manufacturers, and our products have been sold in more than 50 countries.

We are the world leader in pin products, offering higher precision, strength and durability than conventional products.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,Western Union;

Language Spoken:English,Chinese,Spanish

Hot Searches