Name: WQS cyclone sieve

Brand: Dahan

Original: China

Material:Carbon steel

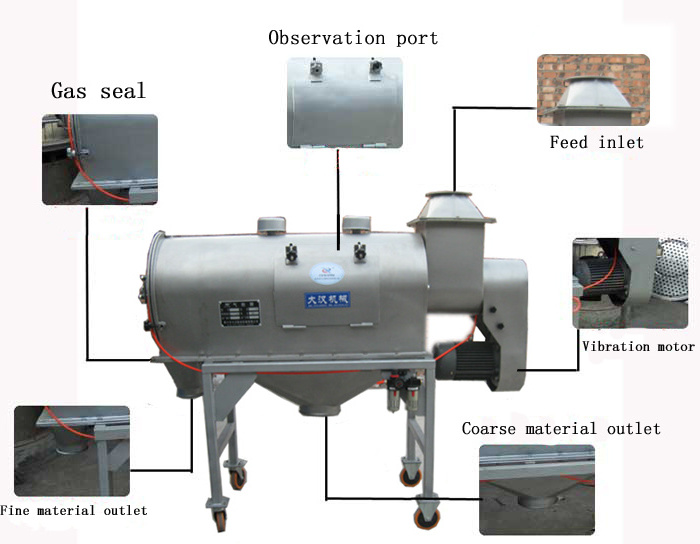

WQS cyclone sieve is also called horizontal airflow screen or horizontal airflow sieving machine due to the shape of lies.ieve cylinder,placed inside the body,after the material through the screw conveying system,mixed with air flow,atomized into network within the cylinder.Through network within the cylinder rotor blade makes the material at the same time by the centrifugal force and whirlwind propulsion,which nearly made the sprayed material,by the fine material outlet,not a net material along the nets are compared in from coarse material outlet.

|

Technical parameter table

|

|

|

|

|||

|

Model

|

Material

|

Powder

|

Application

|

|||

|

WQS18-65

|

Q235A

|

2.2KW

|

500 mesh above

|

|||

|

|

SUS304

|

|

|

|||

|

WQS30-100

|

Q235A

|

4KW

|

500 mesh above

|

|||

|

|

SUS304

|

|

|

|||

|

WQS50-130

|

Q235A

|

5.5KW

|

500 mesh above

|

|||

|

|

SUS304

|

|

|

|||

1.Single or multiple machine use,for a long time continuous operation,safe and reliable.

2.The new outer spherical bearing,prolong service life.

3.The machine is small in size,light weight,smooth and no vibration,no noise,sealed performance is good,no dust,high efficiency.

4.The essence of agglomerate material is broken again.

5.Sieve washed by a whirlwind,can automatically clear the net.

6.The shell structure is novel,simple installation,easy to control.

7.The machine can form a complete set,with the pneumatic conveying system string directly into the wind road,save resources.

8.New design:the gas protection system will be able to purify air after losing to equipment at both ends,can effectively reduce the equipment produced in the process of operating temperature;Of gas bearing formation of isolation layer,thus eliminating dust to enter,effectively prolong the service life of bearing,reduce the maintenance frequency,improve work efficiency.

9.Special design,meet special requirements.

Name: WQS cyclone sieve

Brand: Dahan

Original: China

Material:Carbon steel

Name:

WQS cyclone sieve

Brand:

Dahan

Original: China

The machine is small in size,light weight,smooth and no vibration,no noise,sealed performance is good,no dust,high efficiency.

We provide 12months quality warranty to make sure your machine well runs consistently.

a. Professional engineer design the

production line for you

b.Recommend suitable equipment

according to your special demand.

a.Precheck and accept products

befor edelivery

b.Send technicians to the jobsite

for guiding the installation and

adjustment

c.Training operators and finishing

the check to satisfy your requiremnet

a.Common problem can be solved

through web in 24 hours,complex

problem can be reacted immediately

in 24 hours and solved as soon as

possible

b.To establish long-term friendship,

we will regulary contact with our

customers.

Q:What is the real delivery time of your factory?

A: 10 to 15 days for general series products, meanwhile, customized products would need 20 days to 40 days based on

different situations.

Q: How do you ensure the quality of your products?

A: Generally, our equipments are the most durable type in the industry, this is also the feature of the label impression of DH for most of our customers at home or abroad.However, we do recognized that there do have small amount of the

product which may got faulty or damaged for different reasons.

Q: How do your after-sale service work if the product got damaged?

A: In the gurantee time 12 months, our general aftersale serve.