- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

TM08

-

Power Supply:

-

AC220V

-

Air Supply:

-

0.5MPa ~0.7MPa

-

Vacuum Generation:

-

Built-in vacuum pump

-

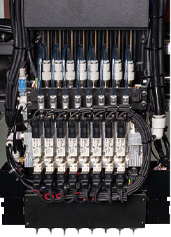

Mounting Head Quantity:

-

8

-

Mounting Speed:

-

35000cph (optimal)

-

PCB Conveying:

-

3-section-rail automatic conveying, PCB support device

-

Nozzle Change:

-

Automatic nozzle change (31-hole nozzle library)

-

Control System:

-

Built-in industrial computer (Windows 7)

-

Feeding System:

-

80 NXT 8mm standard feeder stacks

Quick Details

-

Weight (KG):

-

1450

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

Charmhigh

-

Model Number:

-

TM08

-

Power Supply:

-

AC220V

-

Air Supply:

-

0.5MPa ~0.7MPa

-

Vacuum Generation:

-

Built-in vacuum pump

-

Mounting Head Quantity:

-

8

-

Mounting Speed:

-

35000cph (optimal)

-

PCB Conveying:

-

3-section-rail automatic conveying, PCB support device

-

Nozzle Change:

-

Automatic nozzle change (31-hole nozzle library)

-

Control System:

-

Built-in industrial computer (Windows 7)

-

Feeding System:

-

80 NXT 8mm standard feeder stacks

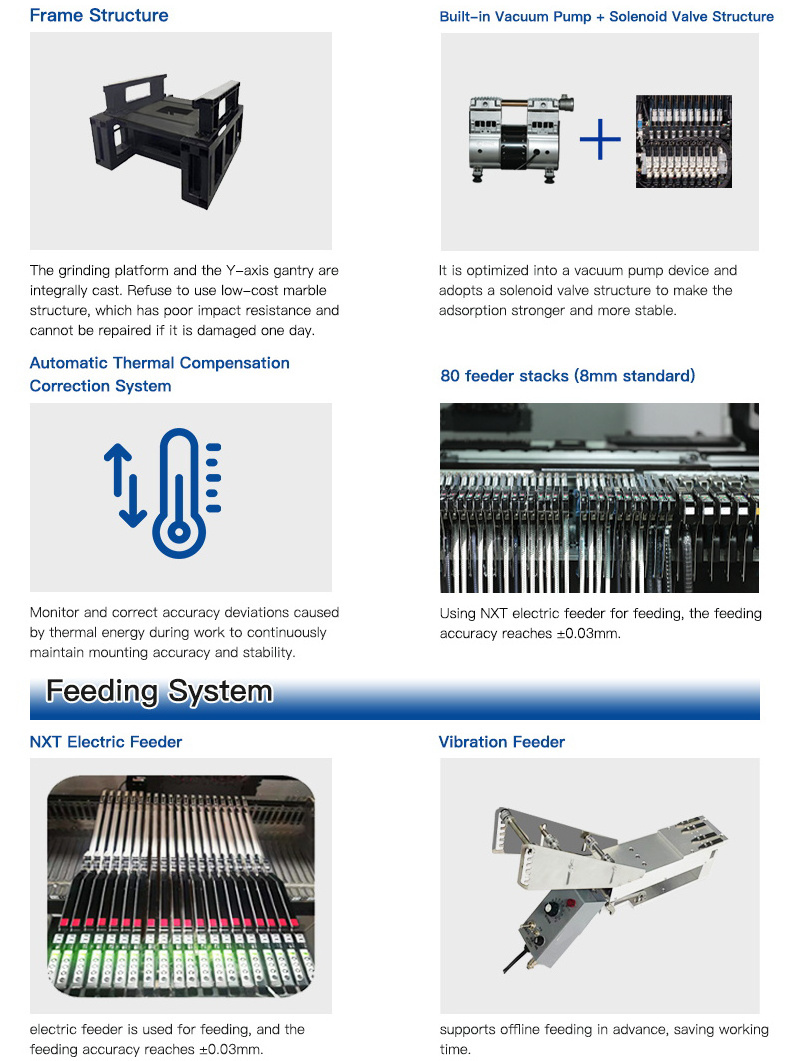

Introduction

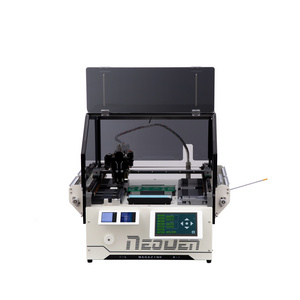

TM08 is an 8-head high-speed, high-precision universal automatic placement machine with high-end configuration, excellent performance and affordable price. Used for R&D prototyping and SMT large-scale production, which can quickly recover investment costs.

Machine features

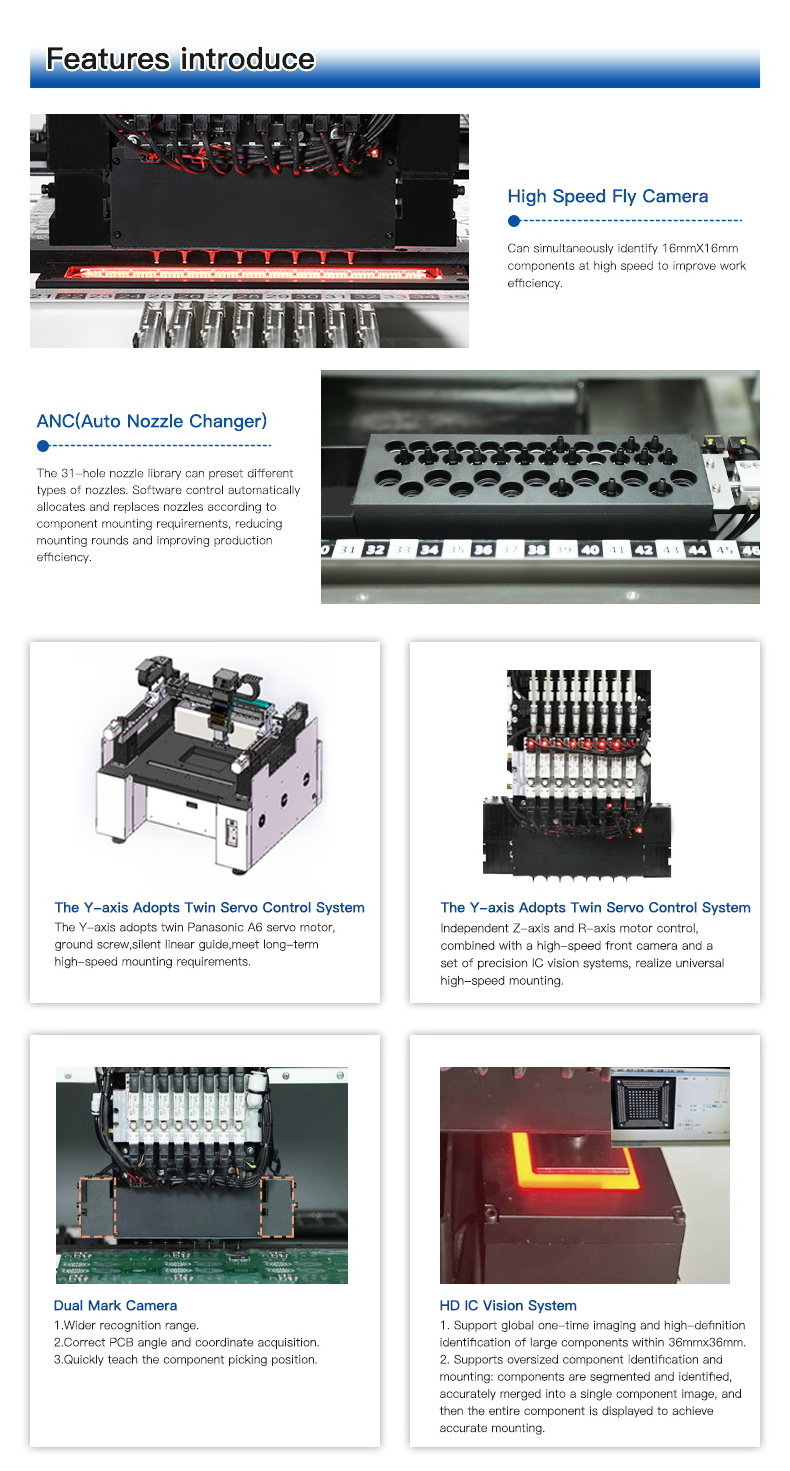

1.Automatic nozzle change (31 sets nozzle library)

2.Thermal Compensation

3.Automatic conveying

4.Optimal speed:35000cph

5.80 NXT 8mm stacks feeder stacks

For more machine features, please consult our account manager

Parts List

|

Item

|

Quantity

|

Item

|

Quantity

|

|

TM08 Pick and place machine

|

1

|

Inner Hexagon Spanner

|

1

|

|

Nozzles

|

16

|

Open-ended Wrench

|

2

|

|

Tool box

|

1

|

Lubricating oil

|

1

|

|

Warranty Card

|

1

|

Vacuum Cotton

|

8

|

|

User Manual

|

1

|

Aviation Plug

|

2

|

|

Test Report

|

1

|

Quick connector

|

1

|

|

Brush

|

1

|

Thimble

|

4

|

|

Tweezer

|

1

|

Mouse Pad

|

1

|

|

|

|

Rubber Damping Pad

|

4

|

|

|

|

|

|

Product Paramenters

|

Dimensions

|

1280mm(L)×1580mm(W)×1500mm(H)

|

|

Weight

|

1450kg

|

|

Power Supply

|

AC220V (50Hz, single phase), 3.5kW

|

|

Air Supply

|

0.5MPa ~0.7MPa

|

|

Vacuum Generation

|

Built-in vacuum pump

|

|

Mounting Head Quantity

|

8

|

|

Mounting Speed

|

35000cph (optimal)

|

|

Mounting Accuracy

|

(XY)±50μm CPK≥1.0

|

|

Component Height

|

≤12mm

|

|

Component Type

|

0201/0402/0603~5050/SOT/SOP/QFP/QFN/BGA, etc.

(resistor/capacitor/diode/triode/LED/IC, etc.) |

|

PCB Thickness

|

0.6mm~3.5mm

|

|

PCB Size

|

450mm(L)×350mm(W) (standard);

1200mm(L)×350mm(W) (optional) |

|

PCB Conveying

|

3-section-rail automatic conveying, PCB support device

|

|

Nozzle Change

|

Automatic nozzle change (31-hole nozzle library)

|

|

Control System

|

Built-in industrial computer (Windows 7)

equipped with monitor, keyboard, and mouse |

|

Drive System

|

X&Y axis driven by Panasonic A6 servo motors (Y axis by double motors); adopting flexible S-curve acceleration and deceleration

|

|

Transmission System

|

X&Y axis adopting ground screw and mute linear guide

(Y axis with double screws) |

|

Feeding System

|

80 NXT 8mm standard feeder stacks

(also suitable for IC tray and stick feeder) |

|

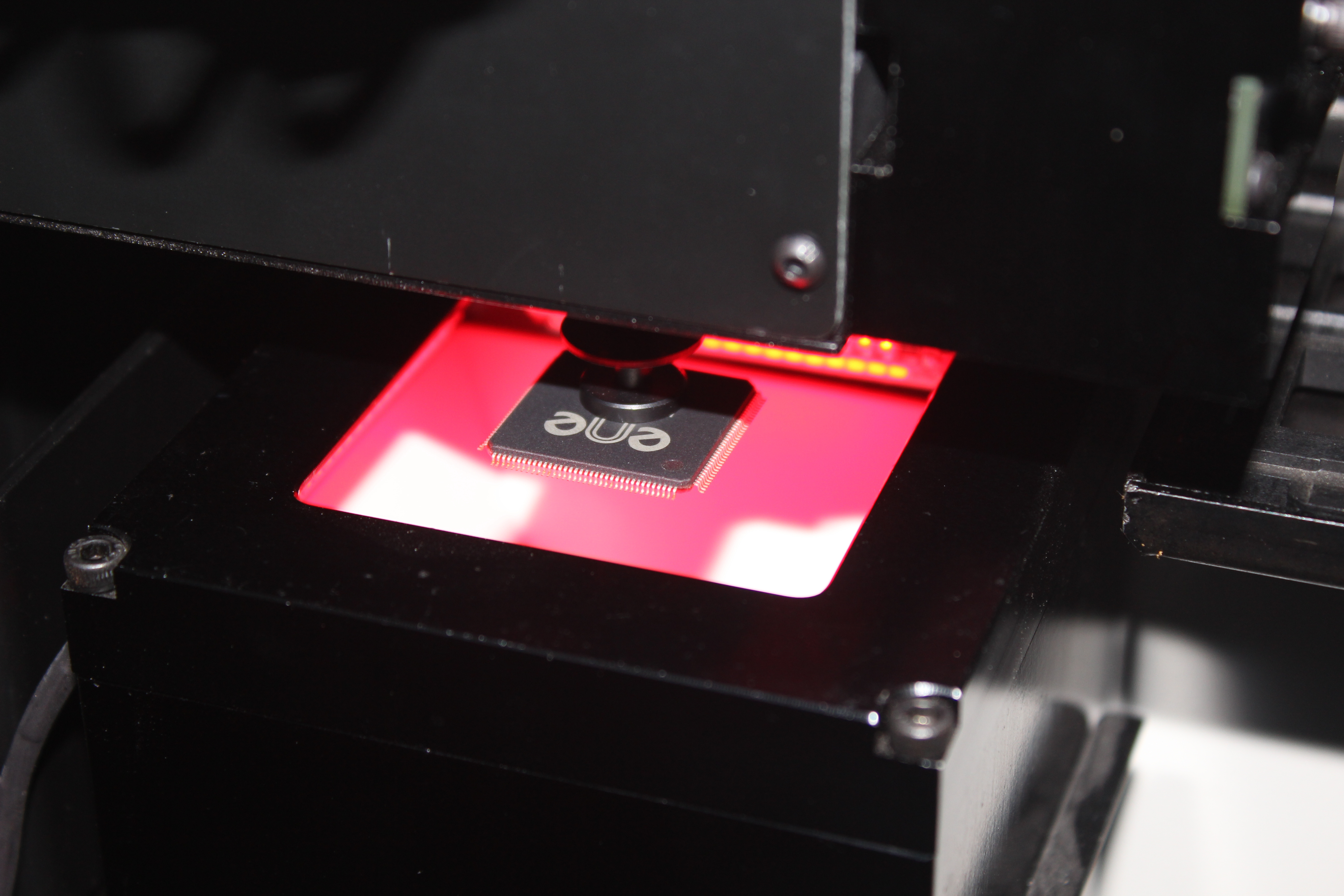

Vision System

|

Fly camera×8 (component size applicable: 16mm×16mm);

IC camera×1 (component size applicable: 36mm×36mm); Mark camera×2 |

Product Details

Hot Searches