High alumina brick is a kind of alumina-silicate refractory material with content of alumina oxide more than 48%. It is calcined

and formed by the raw material of banxite or the material with high content of AL2O3. High thermal stability, the refractoriness is more than 1770℃. Good slag resistance, used for the liner of masonry steel-making electric stove, glass furnace and cement revolver.

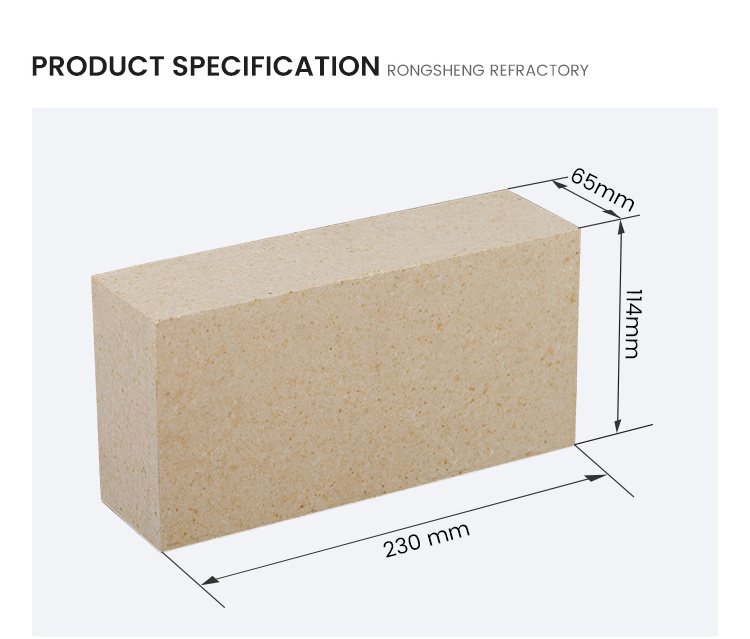

We bring forth high quality High Alumina Bricks, which is manufactured to meet the requirements of neutral refractoriness where safe working temperature is more than 1600 degree centigrade. We offer high Alumina Bricks in different specifications as per customer requirements