- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

within1%

-

Voltage:

-

220V, 220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Aile

-

Weight:

-

460 KG

-

Machine name:

-

linear singele head lotion filling machine

-

Filling speed:

-

20-30 bottles/min

-

Function:

-

liquid filling,capping,cleaning

-

Filling range:

-

15-250ml

-

Suitable bottle:

-

round bottle/square (can be customized)

-

material:

-

Stainless Steel 304/316

-

Control:

-

PLC+ Touch Screen

-

Bottle type:

-

glass,plastic

Quick Details

-

Machinery Capacity:

-

20-30bottles/min

-

Packaging Material:

-

Plastic, Wood

-

Filling Material:

-

Oil, liquid, lotion

-

Filling Accuracy:

-

within1%

-

Voltage:

-

220V, 220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Aile

-

Weight:

-

460 KG

-

Machine name:

-

linear singele head lotion filling machine

-

Filling speed:

-

20-30 bottles/min

-

Function:

-

liquid filling,capping,cleaning

-

Filling range:

-

15-250ml

-

Suitable bottle:

-

round bottle/square (can be customized)

-

material:

-

Stainless Steel 304/316

-

Control:

-

PLC+ Touch Screen

-

Bottle type:

-

glass,plastic

Product Description

Excellent Quality Semi Automatic Aerosol Can Olive oil spray Moisturizing Water Spray Sealing Crimping Machine

Introduction:

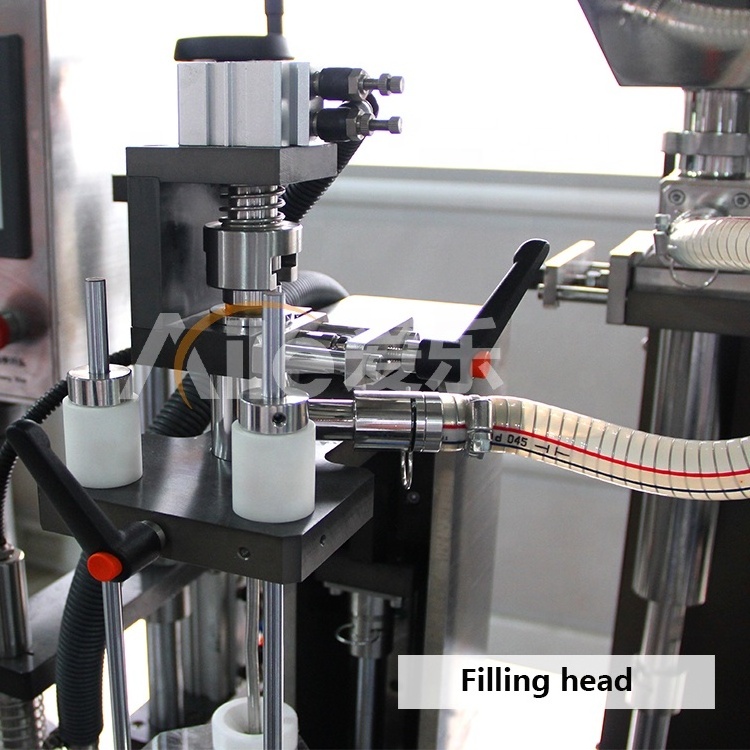

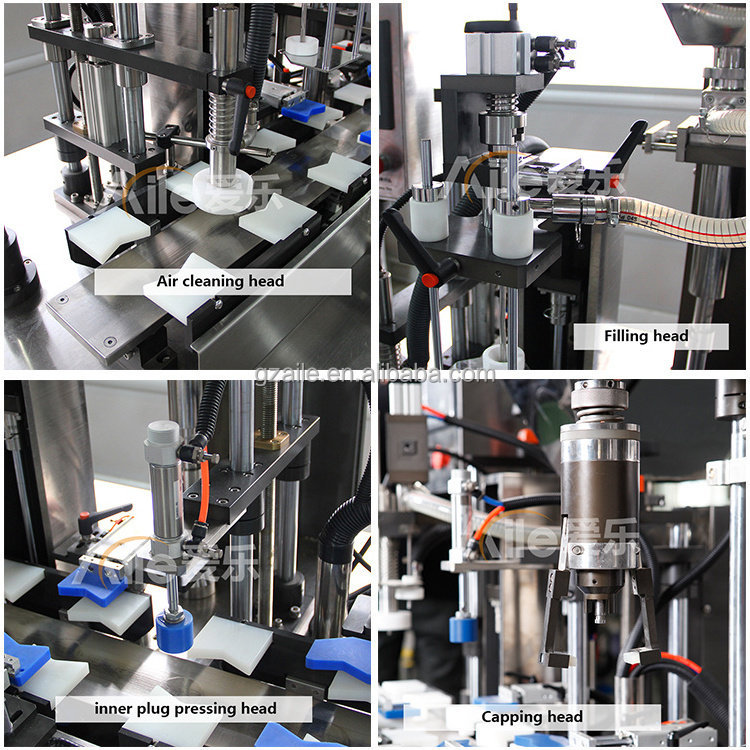

1. Function: Automatic air cleaning + automatic filling +automatic inner plug pressing+ automatic capping

2. Driven by accurate mechanical transmission, which can guarantee the quality of the products effectively.

3. The automatic and uninterrupted producing mode can help to guarantee the production volume you need. We choose good material and parts to assemble our machines.

4.All the parts come in touch with the products are made of food grade stainless steel imported, and all the pneumatic and electrical parts are known brand products from Germany, Japan or Taiwan.

5.It is the innovation design and the good quality parts that ensure these series of machines occupy the leading position

absolutely in the domestic market of liquid packaging.

Features:

1. It integrates air cleaning,filling, collaring(pressing the inner cap) and screwing cap functions.

2. The operation of air cleaning, filling, pressing inner cap, screwing outside cap etc can be finished by only one worker.

3. It fixes and move the bottles by chuck guide device, straight line type working, changing the components for different bottles is not necessary.

4. With easy operation, it is easy to get familiar with its adjustment.

5. The machine is the best choice for working capacity 5000-10000 bottles per day.

Technical Parameter:

1. Working Capacity :10-20b/m

2. Air Cleaning static elimination air cleaning, vacuum suction

3. Filling Nozzle Lifting control by Panasonic servo motor

4. Filling control by Panasonic servo motor

5. Collaring and Capping control by Panasonic servo motor

6. Voltage 220V single phase 2KW

7. Air Source 0.5Mpa~150L/min dried air.

1. Function: Automatic air cleaning + automatic filling +automatic inner plug pressing+ automatic capping

2. Driven by accurate mechanical transmission, which can guarantee the quality of the products effectively.

3. The automatic and uninterrupted producing mode can help to guarantee the production volume you need. We choose good material and parts to assemble our machines.

4.All the parts come in touch with the products are made of food grade stainless steel imported, and all the pneumatic and electrical parts are known brand products from Germany, Japan or Taiwan.

5.It is the innovation design and the good quality parts that ensure these series of machines occupy the leading position

absolutely in the domestic market of liquid packaging.

Features:

1. It integrates air cleaning,filling, collaring(pressing the inner cap) and screwing cap functions.

2. The operation of air cleaning, filling, pressing inner cap, screwing outside cap etc can be finished by only one worker.

3. It fixes and move the bottles by chuck guide device, straight line type working, changing the components for different bottles is not necessary.

4. With easy operation, it is easy to get familiar with its adjustment.

5. The machine is the best choice for working capacity 5000-10000 bottles per day.

Technical Parameter:

1. Working Capacity :10-20b/m

2. Air Cleaning static elimination air cleaning, vacuum suction

3. Filling Nozzle Lifting control by Panasonic servo motor

4. Filling control by Panasonic servo motor

5. Collaring and Capping control by Panasonic servo motor

6. Voltage 220V single phase 2KW

7. Air Source 0.5Mpa~150L/min dried air.

Hot Searches