Corn flour, wheat flour, rice flour, fish powder, bone powder, fresh bone and meat paste etc. Or using the corn feeds, rice feeds, wheat feeds directly, then grinding. Other nutrient can be added together.

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

110- 240 Kw

-

Weight:

-

5000 KG

-

Dimension(L*W*H):

-

2500* 1700* 2200 mm

-

After-sales Service Provided:

-

Online Support

-

Usage:

-

Pet Cat Dog Feed Extruder

-

Function:

-

Producing Animal Feeds Pellets

-

Advantage:

-

Professional Support

-

Capacity:

-

150---1000kg/h

-

Energy:

-

Elctrical

-

Motor brand:

-

Siemens China Beide

-

Name:

-

Pet Feed Making Machine

-

MOQ:

-

1 Set

-

Automatic:

-

Full-antomatic

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

Jinan Delon Machinery

-

Voltage:

-

380V 415V 440V

-

Power:

-

110- 240 Kw

-

Weight:

-

5000 KG

-

Dimension(L*W*H):

-

2500* 1700* 2200 mm

-

After-sales Service Provided:

-

Online Support

-

Usage:

-

Pet Cat Dog Feed Extruder

-

Function:

-

Producing Animal Feeds Pellets

-

Advantage:

-

Professional Support

-

Capacity:

-

150---1000kg/h

-

Energy:

-

Elctrical

-

Motor brand:

-

Siemens China Beide

-

Name:

-

Pet Feed Making Machine

-

MOQ:

-

1 Set

-

Automatic:

-

Full-antomatic

Product Overview

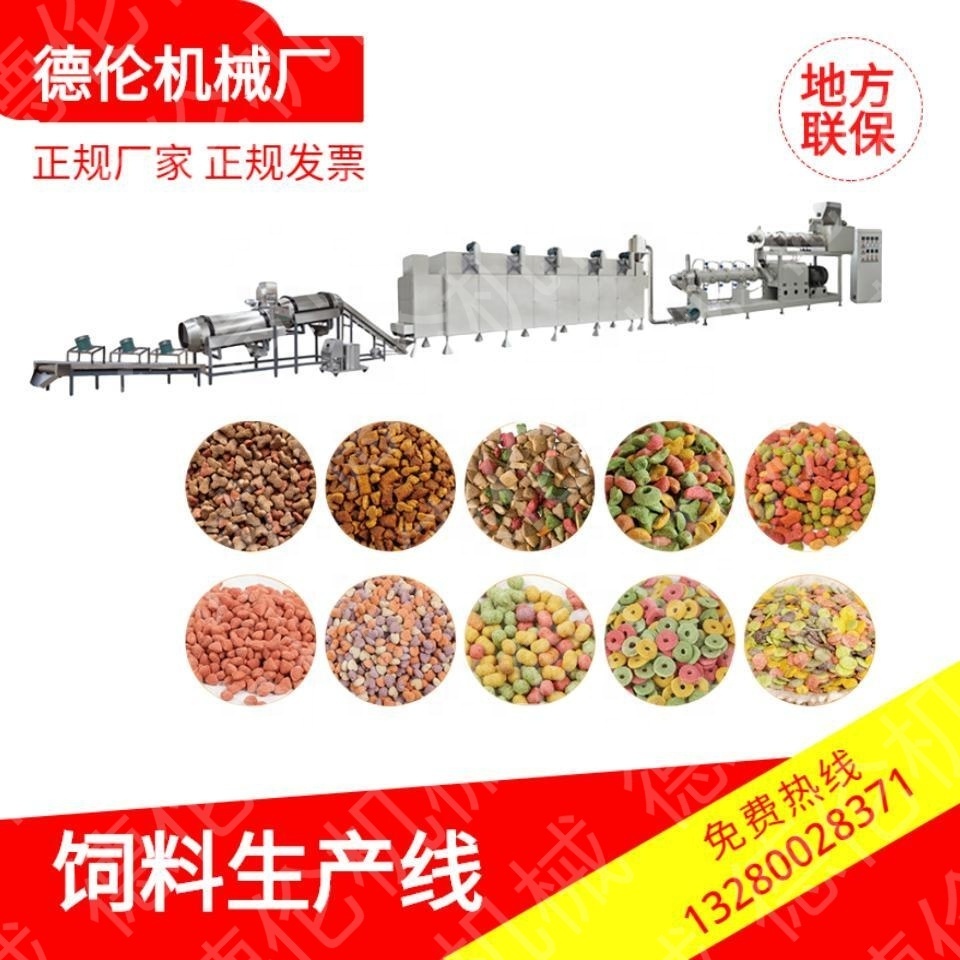

Aquatic Feed Equipment Production Line Pet Food Extruder Equipment Line

What is Pet Food Production Line?

Pet Food Production Line can produce all kinds of pet food, including dog, cat,fox, bird and so on. Dog food extruder uses

twin-screw extruder, the whole work flow canbe controlled exactly by parameter. Different raw material and nutrient elements can be added together according to advanced formula, so the final products are tasty and easy to digest.

Pet food extruder pet food manufacturers adopts new twin-screw extrusion technology to process different types of pellet feed through high temperature and high pressure after mixing all kinds of raw materials. It can process different shapes of feed by changing the mold. Double screw extruder can instantly kill the harmful bacteria in raw materials during the extrusion process. High temperature high pressure produced by twin screw extruder improves the stability and ripening of feed that is beneficial to the absorption of the pets.

Sample for Pet food processing machine dog food extrusion machine

Only for reference

Mould can be changed

* Water content is below 12%

* Digestibility can reach 70%

* Nutrition is comprehensive and balanced

* Easy to carry, long shelf life

* Digestibility can reach 70%

* Nutrition is comprehensive and balanced

* Easy to carry, long shelf life

Details Images

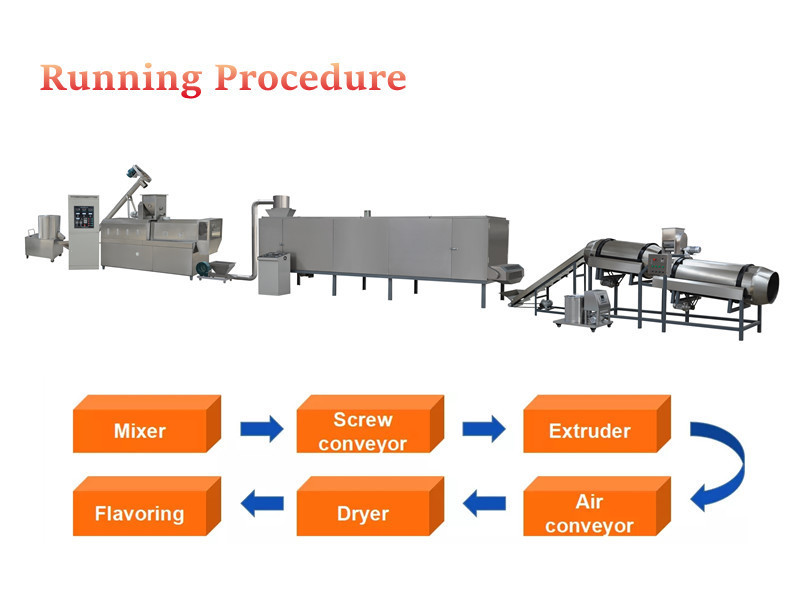

Mixer Machine

Input Voltage: 220-450V/50-60Hz

Installed Capacity: 3-7.5kw

Size: 0.7×0.5×1.1m

Equipment Introduction:

Mixed powder is mixed raw materials, auxiliary materials, machines and water, moderate speed.

Srew Hoister

Input Voltage: 380V/50Hz

Installed Capacity: 3.5kw

Size: 1.5×0.7×2.5m

Screw feeding machine will carry the material inside the sealed stainless steel tube into the feeding machine of the

expansion machine. Without leakage, dust and pollution.

The machine adopts upper uniform and stable material.

Installed Capacity: 3.5kw

Size: 1.5×0.7×2.5m

Screw feeding machine will carry the material inside the sealed stainless steel tube into the feeding machine of the

expansion machine. Without leakage, dust and pollution.

The machine adopts upper uniform and stable material.

---------------------------------------------------------------------------------------------------------------------------------------

Extruder Machine

Input Voltage: 220-450V/50-60hz

Size: 4.5×1.2×2.3m

Equipment Introduction:

Machine consists of feeding system, extruding system, peeling systems, heating system, transmission system, control system.

*The main extruder adopts frequency speed controlling with high automation.

*The screws are made of the stainless steel and special craft, which has the advantage of durable usage, high pressure, and longer life.

*The forced lubrication system ,which can guarantee the equipment transmission life longer.

*Auto-temperature control system and self-cleaning ,which makes it more convenient.

*It has the widest range of applications and can produce different products with different equipment and models.

*The screws are made of the stainless steel and special craft, which has the advantage of durable usage, high pressure, and longer life.

*The forced lubrication system ,which can guarantee the equipment transmission life longer.

*Auto-temperature control system and self-cleaning ,which makes it more convenient.

*It has the widest range of applications and can produce different products with different equipment and models.

---------------------------------------------------------------------------------------------------------------------------------------

Drying machine

Input Voltage: 220-450V/50-60hz

Installed Capacity: 42kw

Size: 5.1×1.2×2.1m

Capacity: 150~200kg/h

Equipment Introduction:

Used for drying.

Produced semi-finished products for dry and dehydrated with drying device,a certain amount of heating device installed inside the

oven , use of electric heating to dry . The most commonly used for extruded products desiccation device.

Installed Capacity: 42kw

Size: 5.1×1.2×2.1m

Capacity: 150~200kg/h

Equipment Introduction:

Used for drying.

Produced semi-finished products for dry and dehydrated with drying device,a certain amount of heating device installed inside the

oven , use of electric heating to dry . The most commonly used for extruded products desiccation device.

---------------------------------------------------------------------------------------------------------------------------------------

Season Machine

Size: 5.1×1.5×2 m

Capacity: 150~200kg/h

Equipment Introduction:

Used to adjust the taste of product. Used to adjust the product taste , in the previous section drum for seasoning after section

roller is used to separate injection, seasoning and injection operations.

Capacity: 150~200kg/h

Equipment Introduction:

Used to adjust the taste of product. Used to adjust the product taste , in the previous section drum for seasoning after section

roller is used to separate injection, seasoning and injection operations.

---------------------------------------------------------------------------------------------------------------------------------------

Product Paramenters

|

Model

|

DL-56

|

DL-70

|

DL-85

|

DL-90

(Gas style drying) |

|

Input Voltage

|

380V/50Hz ,3P

|

380V/50Hz ,3P

|

380V/50Hz ,3P

|

380V/50Hz ,3P

|

|

Installed Power

|

66.84 kw

|

97.65 kw

|

146.65 kw

|

128.2 kw

|

|

Power Consumption

|

45kw

|

76.65 kw

|

97.05 kw

|

116 kw

|

|

Capacity(output)

|

100-150 kg/h

|

200-300 kg/h

|

300-550 kg/h

|

600-1000kg/h

|

|

Fuel

|

Electric/Gas

|

Electric/Gas

|

Electric/Gas

|

Electric/Gas

|

Double extruder

Nutritional and artificial rice making

machine extruder

processing plant

The screw material of the machine is stainless steel. The component is desiged for nitriding treatment, so as

to increase the screw wear with resistance and hardness. Make the screw more durable.

Extruder barrel

Heated by an electric heating ring on the outside of the barrel, it' s divided into three heating zone with three temperature controllers to control the temperature. The barrel is made of

hard carbon steel and treated with boiling and boiling black to prevent oxidation, thus increasing its wear resistance.

Control cabinet

Nutritional and artificial rice making machine extruder

processing plant

the equipment through different control cabinets. Control cabinet can be used according to the customer's local demands to introduce different brands of electrical components and inverter.

Main Machine Models

Our Advantages

Advan

tages

1) This processing line’s core manufacturing technique is twin-screw extrusion.

2) This line extruders are twin-screw extruder, there is one couple of screws inside the barrel. This material’s hardness and strength performance is excellent, which can bear high temperature and high pressure.

3) Our twin-screw extruder has self-clean function.

4) This line automation degree is high, it need only 2-3 workers to operate. The production factors can be quantized and controllable.

5) The extruder is equipped with water cooling system. We can custom-make all the machineries for puffed nutrition powder line as per user’s requirement.

6) All the materials touching food adopts food grade.

7) Our twin-screw extruder is equipped with forced lubrication system. The driving method is tape drive type.

SALES AND SERVICE NETWORK

Our Services

*Our company supply long distance and on-site service.

*Our on-site service includes installation guide, commissioning and training.

*We supply the basic formula of raw materials.

*The user should pay for the international flight ticket of our engineer and translator (if any), and supply food and accommodation in locality. The installment charge is USD80 one person per day.

*User should confirm all production factors and raw materials are prepared before our visiting.

--------------------------------------------------------------------------------------------------------------------------------------------------------

After-sale Service

:

a.) Free consultation service before, during, and after sales;

b.) Free project planning and design services;

c.) Free debugging of equipment until everything is functional;

d.) Provide management of equipment long distance shipping from seller's factory to named place

e.) Provide training of equipment maintenance and operating personally;

f.) Provide new production techniques and formulas;

g.)Provide 1 year complete warranty and life-time maintenance service; The seller is responsible for the nature damage of the

machinery in one year except for man-made damage and wearing parts.

All spare parts and wearing parts are attached with the machinery for free.

b.) Free project planning and design services;

c.) Free debugging of equipment until everything is functional;

d.) Provide management of equipment long distance shipping from seller's factory to named place

e.) Provide training of equipment maintenance and operating personally;

f.) Provide new production techniques and formulas;

g.)Provide 1 year complete warranty and life-time maintenance service; The seller is responsible for the nature damage of the

machinery in one year except for man-made damage and wearing parts.

All spare parts and wearing parts are attached with the machinery for free.

Payment & Packing & Shipping

Packing: Wooden boxes

Certifications

FAQ

Q1. What's the pre-sale service of your company?

Related machines’s technical parameter will be supplied to customer.

1.) According to customer’s factory size, factory layout can be provided in advance.

2.) According to customer’s material cost, general formulation can be prepared well.

3.) Special machine can be supplied as customer’s request.

4.) Professional Advice about Market, machines, processing , materials, packing can be supplied.

5.) Suggesting professional ship agent or helping book ship as customer request.

Q2. What's the after-sale service of your company?

1.) Allocation chart as the buyer’s request will be supplied.

2.) Operation manual will be supplied after shipment.

3.)One year warrantee, life time maintenance with cost price.

4.) Free easy broken spare parts will be sent with container .

5.) First installation can be done by engineer.

6.) Training workers in customer’s factory.

Q3. If machines wearing parts need changing, what should we do?

We can offer the wearing parts all the time, and offer video.

Q4. What's the payment terms if we want to buy the machines?

L/C, T/T 30% down payment, 70% balance before delivery.

Q5. What is the minimum order?

Yes, our company mainly deals with wholesale deals,but if you insist buying one set,

Related machines’s technical parameter will be supplied to customer.

1.) According to customer’s factory size, factory layout can be provided in advance.

2.) According to customer’s material cost, general formulation can be prepared well.

3.) Special machine can be supplied as customer’s request.

4.) Professional Advice about Market, machines, processing , materials, packing can be supplied.

5.) Suggesting professional ship agent or helping book ship as customer request.

Q2. What's the after-sale service of your company?

1.) Allocation chart as the buyer’s request will be supplied.

2.) Operation manual will be supplied after shipment.

3.)One year warrantee, life time maintenance with cost price.

4.) Free easy broken spare parts will be sent with container .

5.) First installation can be done by engineer.

6.) Training workers in customer’s factory.

Q3. If machines wearing parts need changing, what should we do?

We can offer the wearing parts all the time, and offer video.

Q4. What's the payment terms if we want to buy the machines?

L/C, T/T 30% down payment, 70% balance before delivery.

Q5. What is the minimum order?

Yes, our company mainly deals with wholesale deals,but if you insist buying one set,

or you just need one set,we would be very likely to make 1 set for you though.

Hot Searches