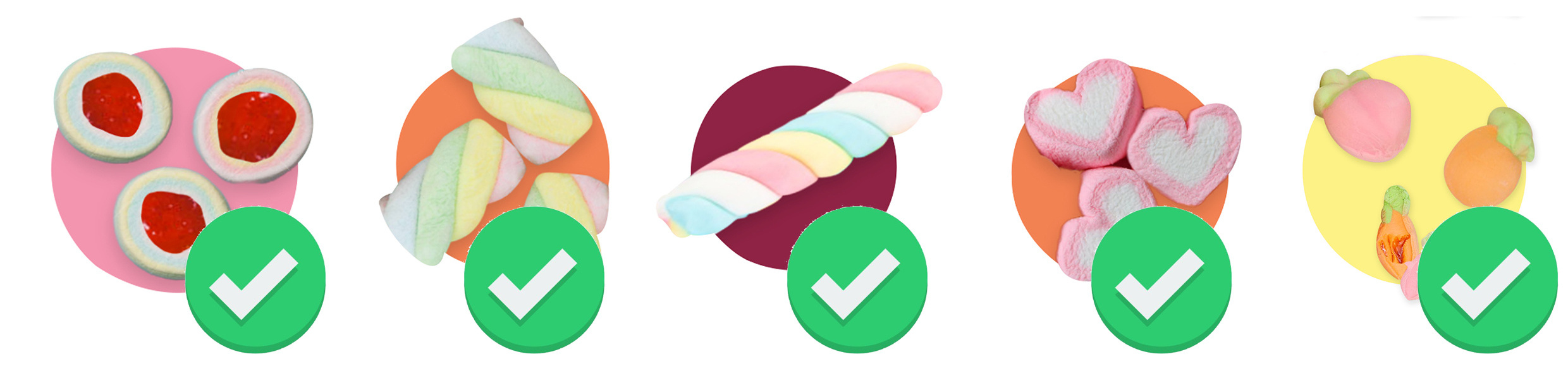

Our marshmallow processing line is complete & continuously produces various kinds of cotton candies (marshmallows) which come in a variety of colors and shapes.This highly aerated confectionery product by our creator machine itis delicately smooth and luxuriously fluffy.Our extruder machine can produce 4colors at single nozzles, and with muntiful shapes or twisted marshmallow rope.Our depositor machine can produce center-filled marshmallow-like jam, chocolate fillings, or two colors like ice cream top.We have an automatic drying system with requires 0 manual till packing.

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

35

-

Weight:

-

2000 KG

-

Name:

-

Marshmallow production line

-

Material:

-

SS304

-

Power Source:

-

Eletric

-

Color:

-

Customized Color

-

Model:

-

100-500

-

MOQ:

-

1pcs

-

Brand:

-

JY

-

Certification:

-

CE/ISO

-

Raw material:

-

Sugar, Gelatin, Water

-

Advantage:

-

Steady Working

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

JY

-

Voltage:

-

220-380V

-

Power:

-

35

-

Weight:

-

2000 KG

-

Name:

-

Marshmallow production line

-

Material:

-

SS304

-

Power Source:

-

Eletric

-

Color:

-

Customized Color

-

Model:

-

100-500

-

MOQ:

-

1pcs

-

Brand:

-

JY

-

Certification:

-

CE/ISO

-

Raw material:

-

Sugar, Gelatin, Water

-

Advantage:

-

Steady Working

Product Description

Marshmallow Making Machine

|

Model

|

JYM-500

|

JYM-800

|

JYM-900

|

JYM-1200

|

|

Production capacity (kg/hour)

|

50-100

|

120-200

|

150-300

|

300-500

|

|

Belt width (mm)

|

500

|

800

|

900

|

1200

|

Features

2) Then the basic slurry is continuously pumped to a cooker till the final moisture level is reached.

3) After cooking, the slurry will be cooled.

4) Then the cooled “marshmallow base” is passed through the continuous aerator.

5) The product then be divided and injection with different colors and flavors.

6) The multi-color product is extruded ,and transported on a cooling conveyor for cooling down.

7) The conditioned marshmallows are dusted top and bottom with starch, or a mixture of both starch and icing sugar in a separate

dust cabin; the product is cut to the required length here.

8) The dust cabin is kept under a strict control to prevent the “dust” spreading throughout the plant. The excess starch/sugar is

removed.

9) Optional: The final is transferred to a chocolate enrobing machine for coating its surface with chocolate.

10) The coated products under cool down.

11) The final products are transferred to a packaging machine.

Aerator

Mixing head

* constructed of a solid piece of stainless steel AISI 316

* Mechanical shaft seal

* Jacketed mixing head stators

* Rotor cooling (optional)

* Pneumatically operated back pleasure regulator valve

* Automatic density control

* Easy CIP, and simple to maintain

* Mechanical shaft seal

* Jacketed mixing head stators

* Rotor cooling (optional)

* Pneumatically operated back pleasure regulator valve

* Automatic density control

* Easy CIP, and simple to maintain

Applications

* Sponge cake

* Merengue

* Chocolate mousse

* Fish and meat mousse

* Yoghurt/quark mousse

* Chiffon cake

* Marshmallow

* Cream

* Merengue

* Chocolate mousse

* Fish and meat mousse

* Yoghurt/quark mousse

* Chiffon cake

* Marshmallow

* Cream

*

Simple operation

*

Reasonable Price

*

4colors in 1 marshmallow

*

Marshmallow rope extruder

*

Center filled depositor

*

CFA auto-mixing system

*

Servo cutting machine

*

Automatic Drying system

Marshmallow depositor

*

center filled

*

ball shape

*

ice-cream shape

Marshmallow Starch system

1# Starch placing

2# starch placing

Starch circulation system

De-Starch system

Drying system

Contact information---------SENT INQUIRY

Certifications

Hot Searches