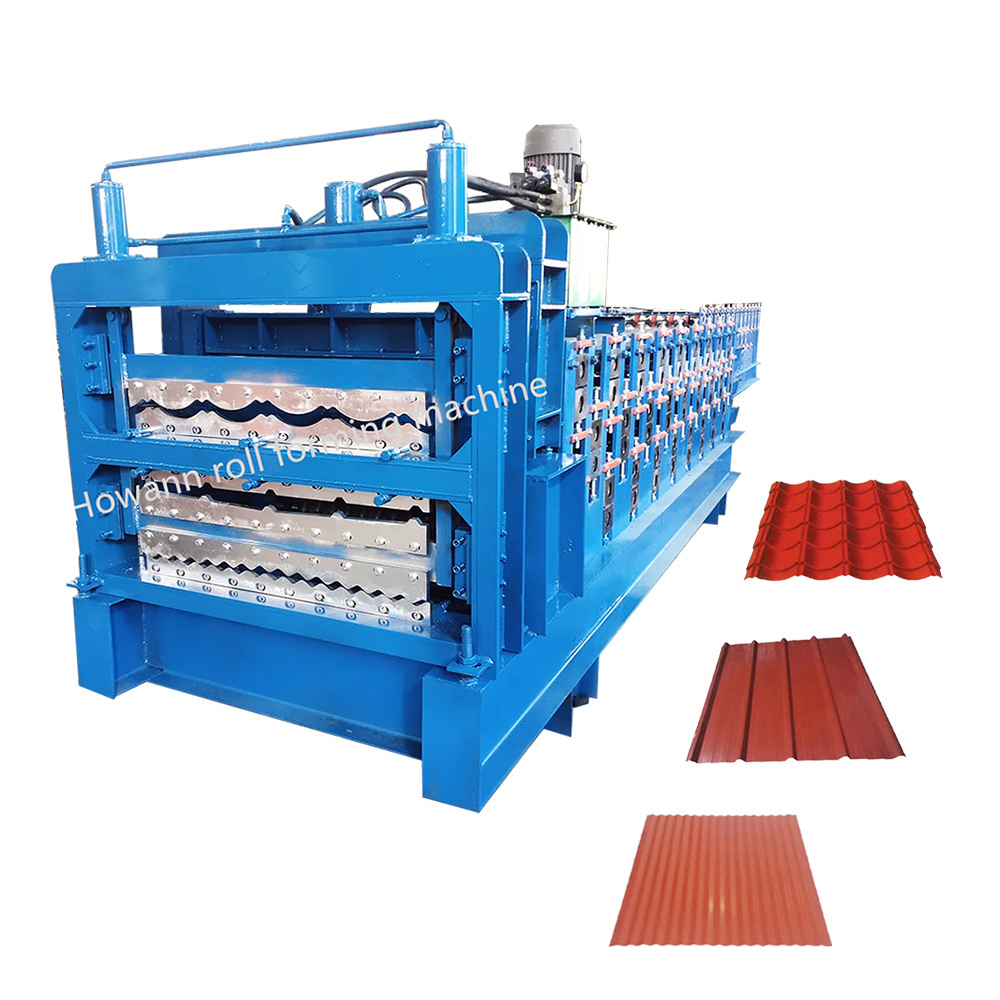

The three-layer tile forming machine is considered to be one of the

most cost-effective

roll forming equipment. It is widely used in industrial and civil buildings, such as factories, warehouses, gymnasiums, etc.

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HOWANN

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

9800*2000*1800mm

-

Weight:

-

5500 kg

-

Product Name:

-

Three Layer Roll Forming Machine

-

Shearing punching method:

-

Front punching, rear cutting

-

Reduction mechanism:

-

2 pieces 15kw with No. 9 planetary cycloid reducer

-

Transfer method:

-

Double row 1.5 inch chain drive

-

Shaft diameter material:

-

Material 45#steel HB220-250

-

Number of roller tracks:

-

16 rows

-

Motor power:

-

15kw

-

Pump power:

-

15kw

-

PLC controlling accurancy:

-

±3mm

-

Certificate:

-

CE, ISO

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HOWANN

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

9800*2000*1800mm

-

Weight:

-

5500 kg

-

Product Name:

-

Three Layer Roll Forming Machine

-

Shearing punching method:

-

Front punching, rear cutting

-

Reduction mechanism:

-

2 pieces 15kw with No. 9 planetary cycloid reducer

-

Transfer method:

-

Double row 1.5 inch chain drive

-

Shaft diameter material:

-

Material 45#steel HB220-250

-

Number of roller tracks:

-

16 rows

-

Motor power:

-

15kw

-

Pump power:

-

15kw

-

PLC controlling accurancy:

-

±3mm

-

Certificate:

-

CE, ISO

Product Details

Three Layer Roll Forming Machine

Advantages:

1. The machine can be

customized

to produce roof panels of different shapes.

2. Our own

updated design

- easy to install and operate.

3. Fully automatic -

saving labor

.

4. The rollers are equipped with bearings, which can eliminate linear speed inconsistencies and make the final product more perfect.

5. Portable PLC control system with

customizable

language.

Our roll forming machine can also be

customized

and manufactured according to

the customers' drawings

.

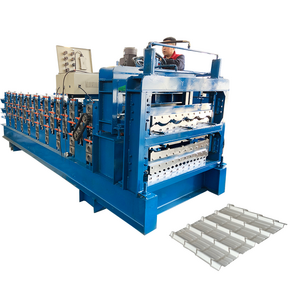

The Working Flow

Uncoiler ----- Molding core ----- Hydraulic System ----- Automatic Control system ----- Step Formed Mechanism -----Automatic Shearing Mechanism ----- Products Receiving Tables

Uncoiler ----- Molding core ----- Hydraulic System ----- Automatic Control system ----- Step Formed Mechanism -----Automatic Shearing Mechanism ----- Products Receiving Tables

Usage:

It is used to expand the raw material and put it on the feeding table.

Capacity:

5T

Material:

Cr 12 High Grade Steel

products,which is used to collect the finished products.

|

|

||

|

Product name

|

Three Layer Roll Forming Machine

|

|

|

Raw material

|

PGI PPGL GI GL

|

|

|

Raw material width

|

1000-1200 mm

|

|

|

Production Capacity

|

12 m/min

|

|

|

Sheet effective width

|

750-1000 mm

|

|

|

Shaft diameter

|

70mm

|

|

|

Main motor power

|

3 KW 4 KW 5.5 KW or as actual demands

|

|

|

Hydraulic motor power

|

3kW/4KW.5.5KW or as actual demands

|

|

|

Voltage

|

380V/ 3 phase/ 50 Hz (or as your requirements)

|

|

|

Control system

|

Automatic PLC control system

|

|

|

Feeding thickness

|

0.3-0.8mm

|

|

|

Cutting method

|

Hydraulic cutting

|

|

|

Warranty of core components

|

1.5 years

|

|

|

Warranty

|

1 Year

|

|

|

Machinery Test Report

|

Provided

|

|

|

Video outgoing-inspection

|

Provided

|

|

|

Applicable Industries

|

Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Retail,

Construction works |

|

If you are interested in our products, please do not hesitate, you can contact us directly, I believe we will have a good cooperation.

Details Images

Hot Searches