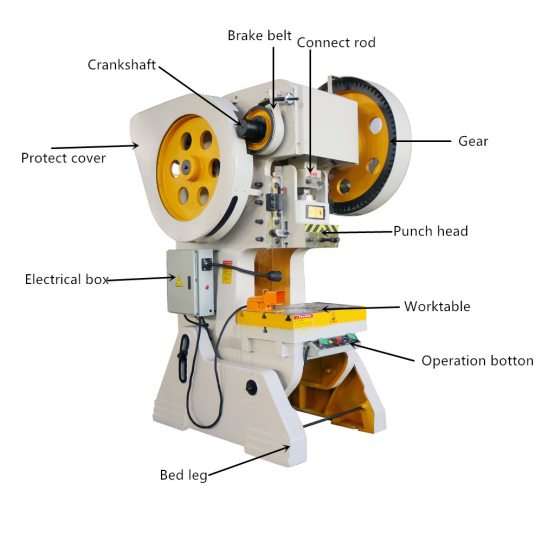

*Open type fixed table for machine body, compact structure, beautiful outlook and high rigidity.*Turn-key type rigid clutch,

flexible movement and reliable performance, double key structure for 100T and plus to effectively overcome the bounce that

happened in the course of stamping.

*Crankshaft arranged in horizontal direction, simple structure and convenient for adjustment and maintenance.

* Crank-down type protectivé device to prevent damage of machine tool due to overload.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/220V Optional

-

Dimension(L*W*H):

-

1130*750*1890mm

-

Motor Power (kW):

-

5

-

Model Number:

-

J23-25

-

Weight (T):

-

3

-

Certification:

-

CE

-

Slide stroke (Times/min):

-

70

-

Slide strokes:

-

70mm

-

Nominal Pressure:

-

250KN

-

Max closing height:

-

200mm

-

Pole distance:

-

240mm

-

Weight:

-

1500KG

-

Body tilting angle:

-

20°

-

Pad thickness:

-

50mm

Quick Details

-

Slide Stroke (mm):

-

70

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Zhongyou

-

Voltage:

-

380V/220V Optional

-

Dimension(L*W*H):

-

1130*750*1890mm

-

Motor Power (kW):

-

5

-

Model Number:

-

J23-25

-

Weight (T):

-

3

-

Certification:

-

CE

-

Slide stroke (Times/min):

-

70

-

Slide strokes:

-

70mm

-

Nominal Pressure:

-

250KN

-

Max closing height:

-

200mm

-

Pole distance:

-

240mm

-

Weight:

-

1500KG

-

Body tilting angle:

-

20°

-

Pad thickness:

-

50mm

80T Steel Shovel Making Machine Hydraulic Power Punching Press with best price

Product Overview

FEATURES AT A GLANCE

PRODUCT SPECIFICATIONS

|

Item

|

J23-63T

|

J23-80T

|

J23-100T

|

J23-125T

|

|

Nominal Pressure

|

630KN

|

800KN

|

1000KN

|

1250KN

|

|

Slide stroke (Times/min)

|

50

|

45

|

45

|

38

|

|

Slide strokes

|

110mm

|

115mm

|

130mm

|

150mm

|

|

Max closing height

|

330mm

|

380mm

|

380mm

|

500mm

|

|

Die height adjustment

|

80mm

|

80mm

|

100mm

|

100mm

|

|

Distance between slider center and machine

|

230mm

|

250mm

|

280mm

|

390mm

|

|

Workbench diameter(mm)

|

440x700

|

480x750

|

540x840

|

720x1100

|

|

Pole distance

|

300mm

|

300mm

|

380mm

|

550mm

|

|

Shank hole diameter

|

60mm

|

60mm

|

60mm

|

60mm

|

|

Shank hole depth

|

70mm

|

80mm

|

80mm

|

75mm

|

|

Pad thickness

|

80mm

|

95mm

|

100mm

|

130mm

|

|

Body tilting angle

|

20°

|

20°

|

20°

|

13°

|

|

Motor power

|

4KW

|

7.5KW

|

7.5KW

|

11Kw

|

|

Weight

|

4000KG

|

5000KG

|

6000KG

|

7000Kg

|

Stamping production is mainly aimed at sheet metal. Through the mold, can make blanking, punching, forming, deep drawing, dressing, fine punching, shaping, riveting and extrusion parts and so on, widely used in various fields. For example, we use switch sockets, cups, cupboards, dishes, computer cases, even missile aircraft. There are a lot of accessories can be produced by the punch through the mold.

Application

80T Power Punching Press Steel Shovel Making Machine

1. Auto parts: automobile body covering parts, braking, fuel tanks, chassis, axle case, bumper; 2. Household appliance: washing

machine, TV, refrigerator, air conditioning, rice cooker and other parts;

3.It can realized punching, cutting, bending, stamping, and trimming etc.

machine, TV, refrigerator, air conditioning, rice cooker and other parts;

3.It can realized punching, cutting, bending, stamping, and trimming etc.

PRODUCT CONFIGURATION

The

principle of

punch is

to crank connecting rod mechanism

, driven by the motor flywheel, flywheel through the shaft and small gear drive big gear, big gear through the clutch drive crankshaft, crankshaft drive connecting rod so that the slider work.

Press machine can be basically divided into

bed part

,

working part

,

control part

and

transmission part

, all components of each part are installed on the bed body.

The press in the workshop is a general press for sheet metal stamping, which can realize various

cold stamping processes

, such as

punching

,

bending

,

shallow drawing

and so on. It's basically a simple working principle.

Our Advantages

Our Services

Pre-sales Service

1. Inquiry and consulting support

2. Sample testing support

3. Recommend the most suitable machine according to customer's purpose

4. Factory visiting welcomed

Mechanical power press power press power press j23

2. Sample testing support

3. Recommend the most suitable machine according to customer's purpose

4. Factory visiting welcomed

Mechanical power press power press power press j23

After-sales Service

FAQ

Q1: How can i get the after-service?

A: We provide one year guarantee

We will send you the spare parts if the problems caused by us.

Any problem, you can call us directly.

Q2: Can I have a visit to your factory before the order?

A: Sure, welcome to inspect our factory.

Our factory address: No219 Xingye Road Tengzhou City Shandong Province

We can pick you up in the Tengzhou station

Hotel booking service is available .

Q3:Are you a factory or trade company?

A: We are manufacturer with own factory , export proportion 50~60%.

Q4:How can i trust your company?

A:We have professional design, we can provide you suitable suggestion and lowest price

Hot Searches