- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

kingdream, Deris

-

Color:

-

blue or golden,red

-

sizes:

-

3 3/4 "(95.3mm)~26"(660.4mm)

-

Bearing type:

-

sealed journal bearing

-

IADC Code:

-

116-637

-

Formation:

-

soft to hard formation

-

Used Warranty:

-

life hours is 150 h and the meter is 1000m

-

Seal type:

-

Metallic seal & rubber seal

-

Packing:

-

Wooden Case

-

Certification:

-

API

Quick Details

-

Weight (KG):

-

110

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

kingdream, Deris

-

Color:

-

blue or golden,red

-

sizes:

-

3 3/4 "(95.3mm)~26"(660.4mm)

-

Bearing type:

-

sealed journal bearing

-

IADC Code:

-

116-637

-

Formation:

-

soft to hard formation

-

Used Warranty:

-

life hours is 150 h and the meter is 1000m

-

Seal type:

-

Metallic seal & rubber seal

-

Packing:

-

Wooden Case

-

Certification:

-

API

Products Description

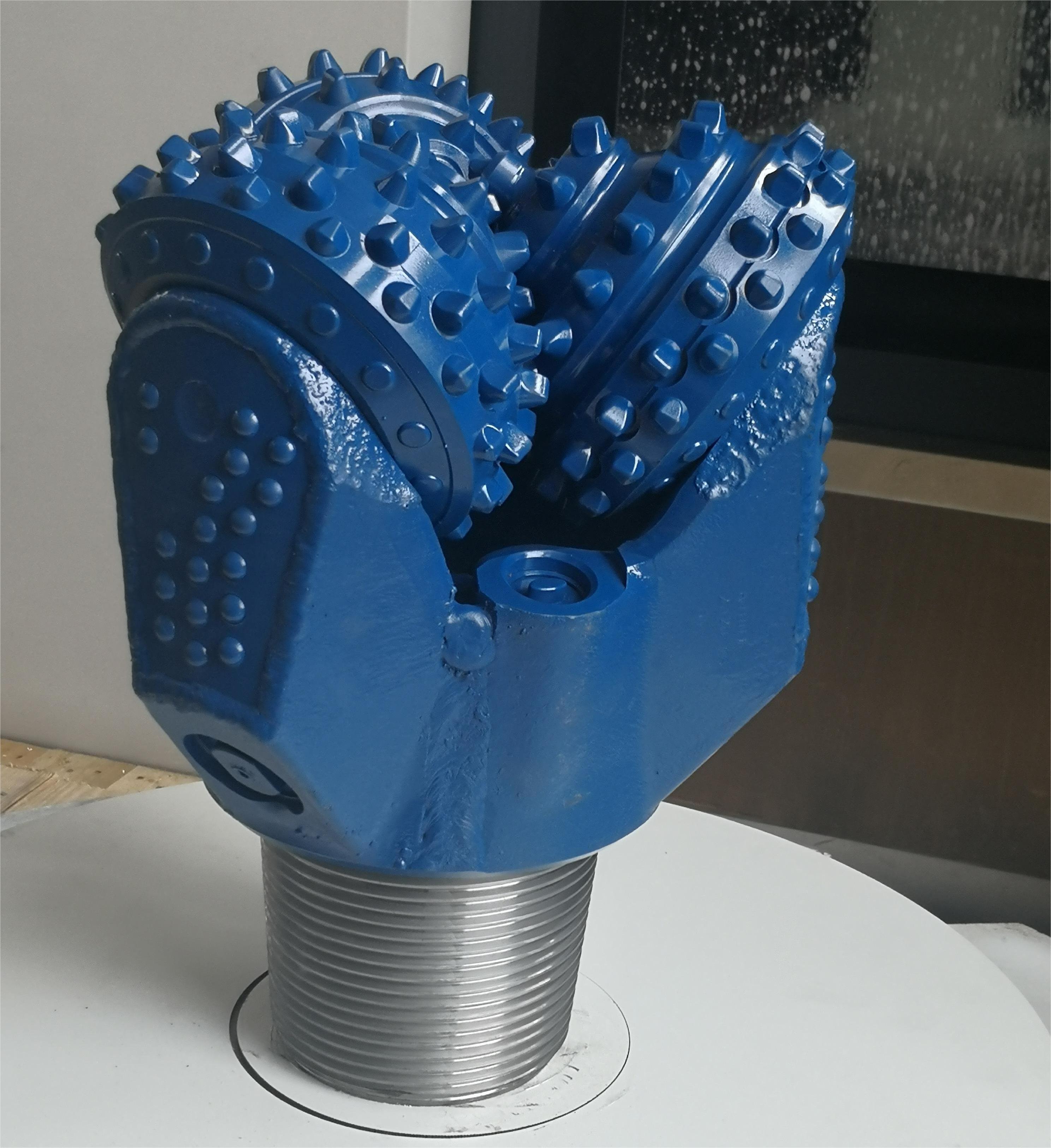

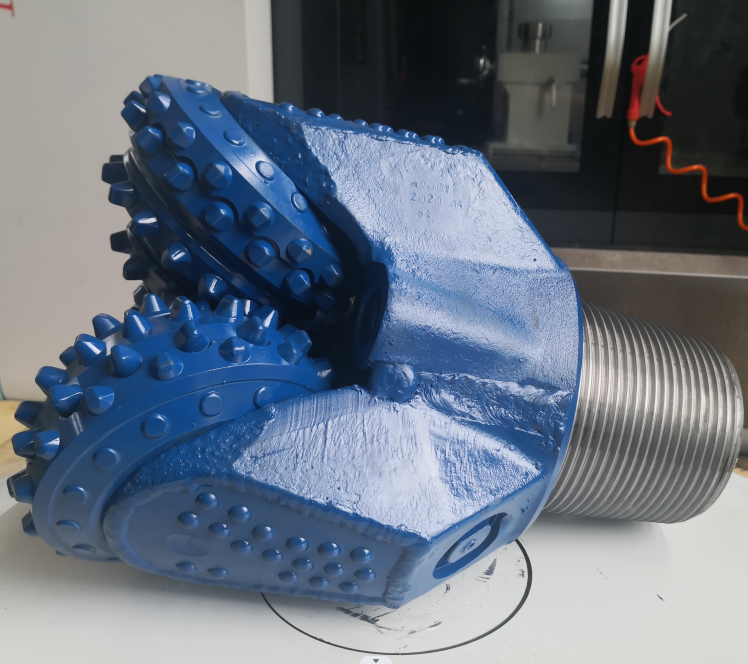

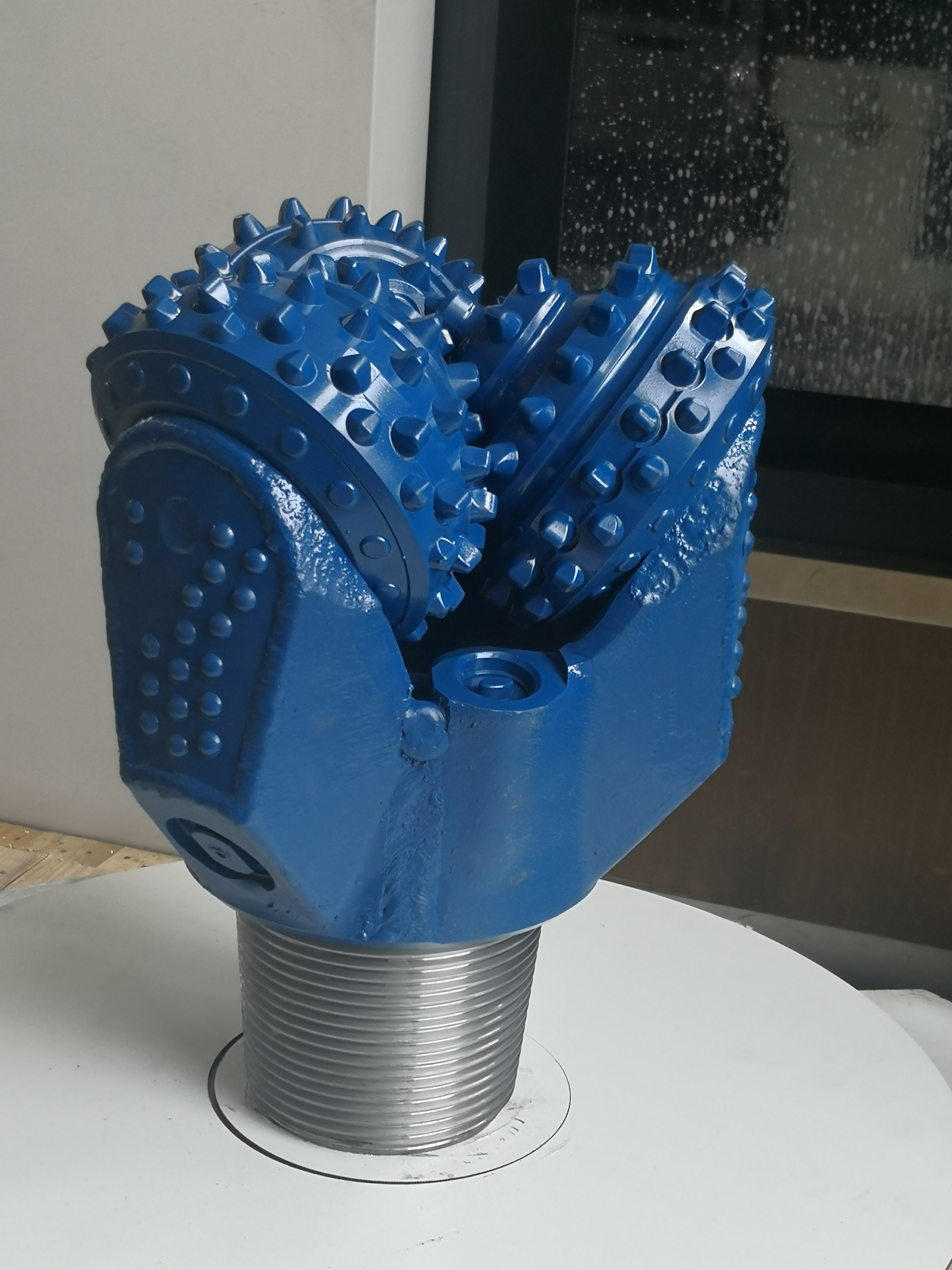

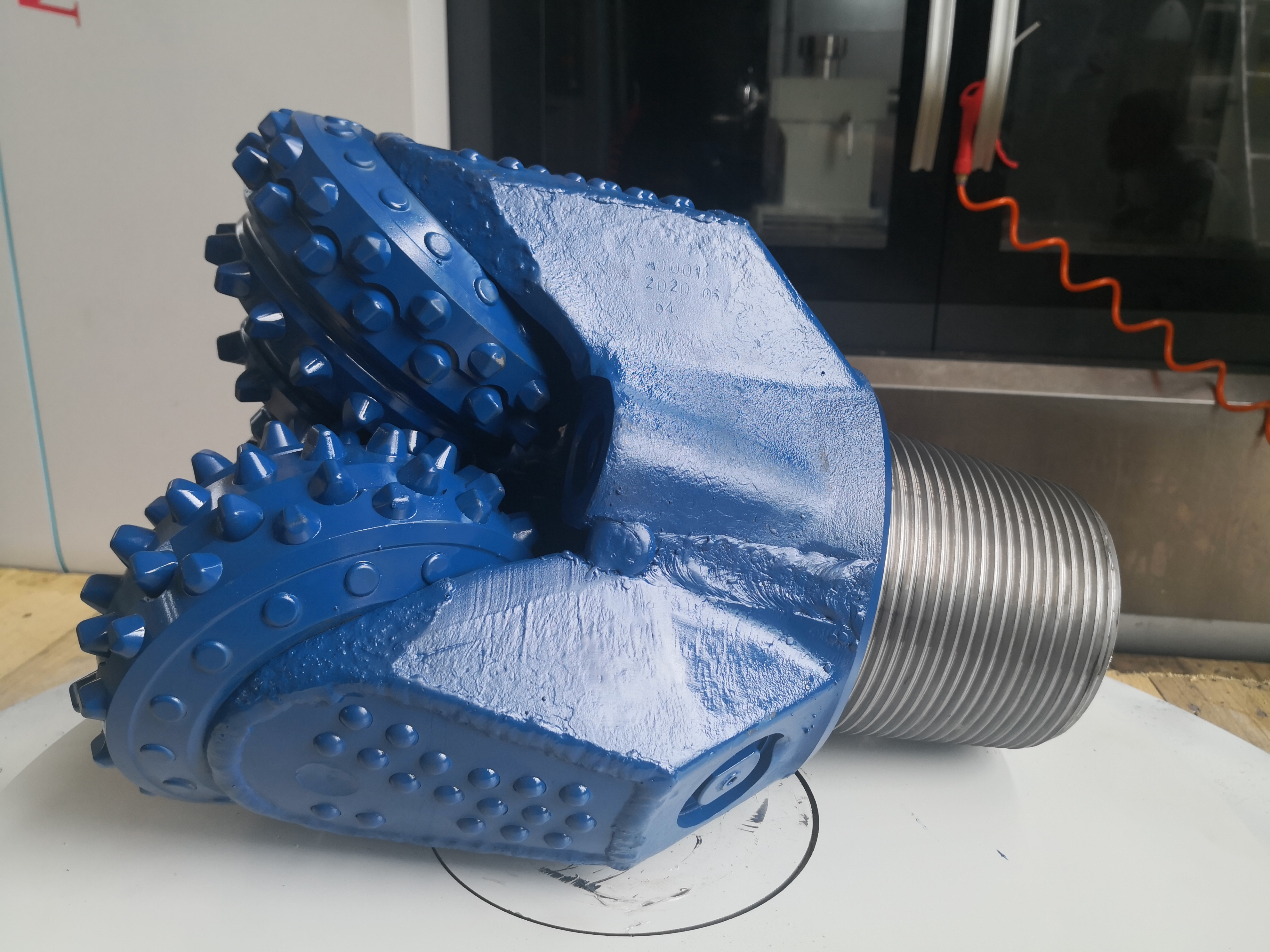

What Is Tricone Drill Bit?

Roller Cone Bits have conical cutters or cones with steel tooth or tungsten carbide buttons around them.As the drill string is rotated,the bit cones roll along the bottom of the borehole in a circular motion.As they roll,new teeth come in contact with the bottom of the hole,chipping the formation below and around the bit tooth.Air or drilling fluid life the crushed rock chips from the bottom of the hole and up the annulus. As rotation continues,another tooth makes contact with the bottom of the hole and creates new rock chips,thus,the process is continuous.Premium tungsten carbide insert (TCI) bits and milled tooth (MT) bits are needed to be designed to withstand high temperatures and endure long running times while drilling through soft to ultra hard formations.

|

Basical Specification

|

|

|

|

Size of tricone bit

|

12 1/4" inch (311.2 mm)

|

|

|

Thread Connection

|

6 5/8" API reg pin

|

|

|

IADC CODE

|

517,527,537,637,737

|

|

|

Bearing type

|

rubber o-ring journal bearing

|

|

|

Operating Parameters

|

|

|

|

WOB

|

0.35~1.05 KN/mm (bit Dia.)

|

|

|

Rotary speed

|

70~40 r/min

|

|

|

Make up torque

|

38-43.4 KN.M

|

|

|

limestone,etc. |

|

|

High Quality Tricone Bits for Deep Bore Hole Well Drilling

The teeth of DS series Wear resistance is enhanced with premium tungsten carbide hardfacing. on the tooth surface, for steel tooth bit.The well comprehensive mechanical drilling performance of premium tungsten carbide inserts is improved with new formulas and new techniques . Multiple gauge protection inserts with gauge trimmers on the gauge surface of the cone,tungsten carbide inserts and hard facing on the shirttail increases gauge holding capability and bearing life.high precision journal bearing with two thrust faces. Balls lock the cone. Hard faced head bearing surface.Cone bearing inlaid with friction-reducing alloy and then silver-plated.Abrasion resistance and seizure resistance of the bearing are improved, and suitable for high rotary speed. Ball lock cones, which optimize the R slot size of tooth and cone and the tolerance clearance of steel ball ,to prevent rock falling off efficiently

The teeth of DS series Wear resistance is enhanced with premium tungsten carbide hardfacing. on the tooth surface, for steel tooth bit.The well comprehensive mechanical drilling performance of premium tungsten carbide inserts is improved with new formulas and new techniques . Multiple gauge protection inserts with gauge trimmers on the gauge surface of the cone,tungsten carbide inserts and hard facing on the shirttail increases gauge holding capability and bearing life.high precision journal bearing with two thrust faces. Balls lock the cone. Hard faced head bearing surface.Cone bearing inlaid with friction-reducing alloy and then silver-plated.Abrasion resistance and seizure resistance of the bearing are improved, and suitable for high rotary speed. Ball lock cones, which optimize the R slot size of tooth and cone and the tolerance clearance of steel ball ,to prevent rock falling off efficiently

Quality Control

In manufacturing, each process goes through an extensive and painstaking testing , quality control is a process that ensures customers receive products free from defects and meet their needs.

1, Raw material selection:To make a good drill bit, it is necessary to select the best material and gate keeping the quality of the material. We purchase the high-quality steel and strictly control the material composition and size, it main includes the detection of the shape, diameter, reamed diameter, length composition, and flaw of the raw material, Tungsten Carbide and Grease are also the best raw materials on the market.Besides, we marked every different piece of materials before transferred to the warehouse.

2, In strict accordance with the ISO9001 international standards for production.

Carefully control every step of the production, complete each of the production process, the production process is including blanking, forging, rough turning, heat treatment,fine turning, quenching, assembling, welding, painting, then storage. Each working process was full inspected, after the qualification, then move to next working process, which to ensure the 100% qualified rate.

3, Sampling observation, numbered, packing and arrange the shipment.

1, Raw material selection:To make a good drill bit, it is necessary to select the best material and gate keeping the quality of the material. We purchase the high-quality steel and strictly control the material composition and size, it main includes the detection of the shape, diameter, reamed diameter, length composition, and flaw of the raw material, Tungsten Carbide and Grease are also the best raw materials on the market.Besides, we marked every different piece of materials before transferred to the warehouse.

2, In strict accordance with the ISO9001 international standards for production.

Carefully control every step of the production, complete each of the production process, the production process is including blanking, forging, rough turning, heat treatment,fine turning, quenching, assembling, welding, painting, then storage. Each working process was full inspected, after the qualification, then move to next working process, which to ensure the 100% qualified rate.

3, Sampling observation, numbered, packing and arrange the shipment.

Advantage

Advantages & Disadvantages

(1)

Versatile

(2)

intial cost is low

(

3)

more control options

(4)

better in varied and complicated rock formation,especailly in hard

(5

)

more impact resistance

(6)

Slow

(7)

possibility to loss cone

(8)

Short service life

One of the largest advantages enjoyed by tricone bits is the length of time they have been around. This longer stretch of time has allowed the design and manufacture of tricone bits to advance significantly, incorporating advances in material technology such as Tungsten Carbide Inserts, or advances in engineering like sealed journal bearings.

Tricone bits are also easier to control in tricky situations, providing more options in regards to torque and Weight On Bit.

Tricone bits are also better for varied rock formations, especially for hard formations. The action of the individual rollers on a tricone bit serves to fracture the rock, making it significantly more flexible in terms of the range of formations one bit can be used on.

High quality

----strictly act according to the ISO9001 standard, and all bits are manufactured according to strict standards, set forth by the American Petroleum Institute (API).

Propessional Equipment---- No matter raw material selection, or processing technology are selected is the industry leading technical equipment.

22 Years History---- From 2000 to 2022, customers are located all over the world and win a good reputation.

Don’t see the bit you are looking for? Give us a call, we can customize any bit to fit your unique circumstances..

Propessional Equipment---- No matter raw material selection, or processing technology are selected is the industry leading technical equipment.

22 Years History---- From 2000 to 2022, customers are located all over the world and win a good reputation.

Don’t see the bit you are looking for? Give us a call, we can customize any bit to fit your unique circumstances..

Main Products We Provide

We mainly provide Tricone Bits(Rock Drilling Bits), DTH Bits and PDC Bits for mining rock drill , water well drilling and oil welldrilling.

Don’t see the bit you are looking for? Give us a call, we can customize any bit to fit your unique circumstances.

1). Tricone Bits:

a). Type: Tungsten Carbide Insert (TCI)

b). Formation Application: Soft to Hard Formation

c). Size Available: 3''~26''

d). Popular IADC Code: IADC545,645,725,735,745,825,835

2). DTH Bits:

a). Type: Tungsten Carbide Insert (TCI)

b). Formation Application: Soft to Hard Formation

c). Size Available: 2.8''~26''

d). Popular IADC Code: IADC117/137, 217/237, 317/337, 417/437, 517/537, 617/637

3). PDC Bits:

a). Type: Matrix Body and Steel Body

b). Formation Application: Soft to Hard Formation

c). Size Available: 3 1/2''~26''

d). Popular IADC Code: 121/122/123, 221/223/224, 323/324/332/333/334/343,

423/424/432/433/443

Don’t see the bit you are looking for? Give us a call, we can customize any bit to fit your unique circumstances.

1). Tricone Bits:

a). Type: Tungsten Carbide Insert (TCI)

b). Formation Application: Soft to Hard Formation

c). Size Available: 3''~26''

d). Popular IADC Code: IADC545,645,725,735,745,825,835

2). DTH Bits:

a). Type: Tungsten Carbide Insert (TCI)

b). Formation Application: Soft to Hard Formation

c). Size Available: 2.8''~26''

d). Popular IADC Code: IADC117/137, 217/237, 317/337, 417/437, 517/537, 617/637

3). PDC Bits:

a). Type: Matrix Body and Steel Body

b). Formation Application: Soft to Hard Formation

c). Size Available: 3 1/2''~26''

d). Popular IADC Code: 121/122/123, 221/223/224, 323/324/332/333/334/343,

423/424/432/433/443

Working principle

1) Revolution of drill bit The revolution speed of the drill bit is the rotation speed of the turntable or the

down hole power drilling tool. When the drill bit revolves, the cone also rotates around the axis of the drill bit. The linear speed of each row of teeth on the cone rotating around the axis of the drill bit is different, and the linear speed of the outer row of teeth is the largest.

3) Longitudinal vibration (axial vibration) impact crushing of the drill bit The change of the position of the wheel center makes the drill bit reciprocate up and down along the axial direction, which is the longitudinal vibration of the drill bit, which is related to the drill bit structure parameters such as tooth height and tooth spacing and lithology. Soft strata have small amplitudes, while hard strata have large amplitudes. The vibration frequency is proportional to the number of teeth and the speed of the cone.

4) Sliding shear breaking action of drill bit Crushing different types of rock requires different slippage of the drill bit, which is determined by the structural parameters of the drill bit. In soft formations, bit slippage is large, and in hard formations, it should be as small as possible or not slipped.

down hole power drilling tool. When the drill bit revolves, the cone also rotates around the axis of the drill bit. The linear speed of each row of teeth on the cone rotating around the axis of the drill bit is different, and the linear speed of the outer row of teeth is the largest.

2) Rotation of the drill bit When the drill bit rotates, the counterclockwise rotation of the cone

around the axis of the tooth palm is called auto rotation. The rotation speed of the cone is determined by the revolution speed of the drill bit, and is related to the effect of the teeth on the bottom of the well.

around the axis of the tooth palm is called auto rotation. The rotation speed of the cone is determined by the revolution speed of the drill bit, and is related to the effect of the teeth on the bottom of the well.

3) Longitudinal vibration (axial vibration) impact crushing of the drill bit The change of the position of the wheel center makes the drill bit reciprocate up and down along the axial direction, which is the longitudinal vibration of the drill bit, which is related to the drill bit structure parameters such as tooth height and tooth spacing and lithology. Soft strata have small amplitudes, while hard strata have large amplitudes. The vibration frequency is proportional to the number of teeth and the speed of the cone.

4) Sliding shear breaking action of drill bit Crushing different types of rock requires different slippage of the drill bit, which is determined by the structural parameters of the drill bit. In soft formations, bit slippage is large, and in hard formations, it should be as small as possible or not slipped.

Common fault analysis of Tricone bits

|

Common fault

|

Fault description

|

Method

|

|

Early wear of the shirttail

|

Abrasive formations, bent drill rod, seriously worn stabilizer and insufficient air for drilling rate attained etc, are all the

causes which result in premature shirttail wear. In this case, the configuration of cones is good and the amount of inserts wear is small. Shairttail wear can also allow the big roller bearings to fall out resulting in bit failure. |

The designer should strength the shirttail with certain measures to increase the wear-resistance capacity of shirttails.

|

|

Early wear and loose movement of the bearing

|

Excessive weight on bit, insufficent air to clean the hole and/or cool the bearing, leads to bearings overheating due to improper

cooling and poor cuttings removal can shorten the service life of bit bearing. |

Reduce bit pressure and increase air pressure

|

|

Cutting structure failure

|

Excessive WOB or Rotation speed; Wrong bit selection; Cuttings blowing in bad conditions caused repeating crushing

|

Correctly select operating parameters and rotary types for specific working conditions

|

How to choose suitable tricone rock bit

The suitable bits with higher cost performance is the most important.Such as, high class bits are not cost-effective for general water well drilling. Because the water well drilling rig can’t drive the supreme quality bits to perform their best.But for deep water drilling, first class rock bits are cost-effective though it’s worth more.When inquiring, Please tell us more details about your drilling project so that we can recommend best suitable bits for your reference.

Tricone Bit Instruction

Transporation :

Storage:

Validity :

Type Selection:

Tricone Bit Instruction

Transporation :

As the small volume of tricone bit and heavy weight,safety should be noticed during transportation.The package is carton or wooden case.Waterproof and damp proof should be noticed during transportation.

Storage:

There is rubber piece and lubricating grease in tricone bit,So it can not be stored in the open air.and be damp proof. The temperature should be 0-40 centigrade degrees. No welding,heating and other processing is permitted on bit.

Validity :

The roller bit should be utilized within four years after resembling.

Type Selection:

Appropriate bit should be choosen according to drilling formation lithology and reference on the conjoint well.

How TCI Tricone Bit Work?

TCI Tricone Bit also named rotary drill bit is an ideal solution for soft, medium, or hard rock formations, it is connected with the drill stem and rotates along with it, and drive cones to pressed on the rock. Each cone rotates round the axis of its leg and three cones simultaneously revolve around the bit center. The tungsten carbide inserts on the cone shell cause the formation to spall under the weight on bit and the impact load of cone rotating, the debris will be discharged out to hole by compression air.

Tricone bits come in several different varieties, and can deal with a wide range of different rock formations. It is important to know the type of formation you are drilling in when selecting a drill bit. The medium formation TCI tricone bits features aggressive chisel tungsten carbide inserts on the heel rows and inner rows. This design provides a fast drilling rate and added cutting structure durability in medium to medium hard for mations. The HSN rubber O-ring provides adequate sealing for bearing durability.

Tricone bits come in several different varieties, and can deal with a wide range of different rock formations. It is important to know the type of formation you are drilling in when selecting a drill bit. The medium formation TCI tricone bits features aggressive chisel tungsten carbide inserts on the heel rows and inner rows. This design provides a fast drilling rate and added cutting structure durability in medium to medium hard for mations. The HSN rubber O-ring provides adequate sealing for bearing durability.

Application

Medium to Medium-Hard Formation For use in moderately abrasive consolidated formations with compressive strength ranging between 140 – 485 Mpa such as hard limestone, quartzite, granodiorite, and medium grade metamorphic formations Cutting structure: These bits are characterized by moderately spaced conical inserts with medium projection. This configuration promotes good penetration

rates in medium hard and moderately abrasive formations. Smaller carbide inserts are provided on the gage and inner rows or hard metal is deposited in the nose area to contain shell erosion and improve performance.

1.Compression Strength: 20,000 – 70,000 psi

2.Drilling Speeds: 60 – 100 rpm

3.Jet Circulation: All sizes

4.Weight on Bit (WOB): 2,500 – 7,000 lbs/in of bit diameterat

Bits thread are manufactured according to API standards.

rates in medium hard and moderately abrasive formations. Smaller carbide inserts are provided on the gage and inner rows or hard metal is deposited in the nose area to contain shell erosion and improve performance.

1.Compression Strength: 20,000 – 70,000 psi

2.Drilling Speeds: 60 – 100 rpm

3.Jet Circulation: All sizes

4.Weight on Bit (WOB): 2,500 – 7,000 lbs/in of bit diameterat

Bits thread are manufactured according to API standards.

COMPANY

Our company established in 2000. Our company have been grown into a leading manufacturer of drilling bit and a supplier of high quality drilling tools. We are good at designing, manufacturing, and distributing Oil well , gas well, deep water well, crossing ,mine, pile foundation ,Geological exploration, construction industry drilling tools as well as finding customer solutions for complex problems.

Our company is committed to provide our customers with the best quality tools, accessories and service in the industry. We are supported by many years of experience, trained professionals and a full machine shop. Hejian Deris owns a high reputation in the construction, exploration, water well, geothermal, mining, and oil & gas industries owe to we can provide dependability and highquality products at excellent value.

Products include: Tricone bit (steel tooth & TCI bit), PDC drill bit (matrix & steel body), step drag bit, HDD Reamer bit (Hole opener), tricone bit cutters, replacement roller cones, stabilizer, Drill pipe, drill collar and so on. We offer a dynamic range of products and solutions. Our diverse products can meet your industry various demands.

Our company has a professional team of core technical personnel,from Drilling tool designers drafting drawing ,implementation to machining fabrication, assembly and distribution, we are ready to meet any of your industry drilling challenge. We know that it is important to work closely with our customers and to develop a Win-win relationship based on trust.

Our company is committed to provide our customers with the best quality tools, accessories and service in the industry. We are supported by many years of experience, trained professionals and a full machine shop. Hejian Deris owns a high reputation in the construction, exploration, water well, geothermal, mining, and oil & gas industries owe to we can provide dependability and highquality products at excellent value.

Products include: Tricone bit (steel tooth & TCI bit), PDC drill bit (matrix & steel body), step drag bit, HDD Reamer bit (Hole opener), tricone bit cutters, replacement roller cones, stabilizer, Drill pipe, drill collar and so on. We offer a dynamic range of products and solutions. Our diverse products can meet your industry various demands.

Our company has a professional team of core technical personnel,from Drilling tool designers drafting drawing ,implementation to machining fabrication, assembly and distribution, we are ready to meet any of your industry drilling challenge. We know that it is important to work closely with our customers and to develop a Win-win relationship based on trust.

Service

1.Pre-sale service:

Act as a good adviser and assistant of clients enable them to get rich and generous returns on their investments .

1.Select equipment model.

2.Design and manufacture products according to client's special requirement ;

3.Train technical personnel for clients .

2.Services during the sale:

2.Design and manufacture products according to client's special requirement ;

3.Train technical personnel for clients .

2.Services during the sale:

1.Pre-check and accept products ahead of delivery .

2. Help clients to draft solving plans .

3.After-sale services: Provide considerate services to minimize clients' worries.

3.Complete After-sales service,

1.professional engineers available to service machinery at home or oversea.

2. 24 hours technical support by e-mail.

3.Other essential technological service. We are factory direct sales, large inventory, fast delivery, high quality.

2. Help clients to draft solving plans .

3.After-sale services: Provide considerate services to minimize clients' worries.

3.Complete After-sales service,

1.professional engineers available to service machinery at home or oversea.

2. 24 hours technical support by e-mail.

3.Other essential technological service. We are factory direct sales, large inventory, fast delivery, high quality.

Packing and Shiping

Package Type : wooden case ,also be packaged according to customers requirement Transportation : by sea , by air or land transportation . Less than 50kg shipping by courier better Delivery : If we have stock, the delivery time will need about 2~3 working days. In general, common size tricone bits and pdc bit, we have stock.If we have no stock, such as the tci reamer and pdc hole opener, it will be 7-10 working days in total.

FAQ

The information you may like to know before order:1. Does your company have its own factory?

A: Yes , we are local famous company with a professional drill bit manufacturer Deris in China.

2. Are product quality and customer service good?

A: Company tent of Deris: Quality first, after-sales service first. All of our are certified to ISO 9001. We insist customer supremacy of credibility. Advanced technology and equipment ensuring the quality satisfy international standards.

3 . How about the packing & Delivery?

A: We used high quality export carton container and wooden case in order to ensure that product reaches its destination safely.

4. About lead time and shipping time?

A: The lead time depend on quantity of order. Usually choose seaworthy packing , urgent order or small order are sent by air parcel after received your agreement.

5. How to order our product?

A: Send the inquiry detail item description or with Model number. If there is no packing demand we take it as shipping. If possible please attach one reference picture to avoid any misunderstanding or any links from our website for we get a accurate understanding.

6. How can I access your company website?

Our website is : https://hjdrs.en.alibaba.com/

Contact

Hot Searches