- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V

-

Power:

-

120W

-

Weight:

-

130 KG

-

Effective evaporation area:

-

0.12m2

-

Condensation area:

-

0.1m2

-

Barrel diameter:

-

80mm

-

Constant pressure feeding funnel volume:

-

0.5L

-

Processing flow:

-

300ml/min

-

Motor power:

-

80W

-

Max speed:

-

1100rpm

-

key word:

-

Molecular Distillation

-

After Warranty Service:

-

Video technical support

-

Marketing Type:

-

Hot Product 2021

Quick Details

-

Applicable Industries:

-

Extraction

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

HEB

-

Voltage:

-

220V

-

Power:

-

120W

-

Weight:

-

130 KG

-

Effective evaporation area:

-

0.12m2

-

Condensation area:

-

0.1m2

-

Barrel diameter:

-

80mm

-

Constant pressure feeding funnel volume:

-

0.5L

-

Processing flow:

-

300ml/min

-

Motor power:

-

80W

-

Max speed:

-

1100rpm

-

key word:

-

Molecular Distillation

-

After Warranty Service:

-

Video technical support

-

Marketing Type:

-

Hot Product 2021

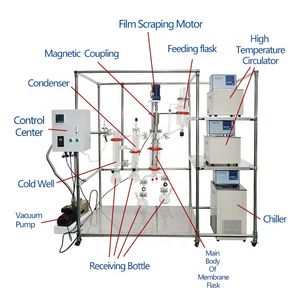

HEB-80 Hemp Extraction & Oil Distill Glass Molecular Wiped Film Distillation

Summary:

HEB wiped film evaporator, it is a process of separation, purification and concentration of natural products, complex and thermally sensitive molecules for example vitamins and polyunsaturated fatty acids. This process is characterized by short term exposure of the distillate liquid to high temperatures, by high vacuum pressure (around 1024 mmHg) in the distillation column and a small distance between the evaporator and the condenser around 2 cm, where fluids are in the free molecular flow regime, i.e. the mean free path of molecules is comparable to the size of the equipment. This process has the advantages of avoiding the problem of toxicity that occurs in techniques that use solvents as the separating agent, and also of minimizing losses due to thermal decomposition.

Technical Parameters:

|

Model |

HEB-60 |

HEB-80 |

HEB-100 |

HEB-150 |

HEB-200 |

HEB-300 |

|

Effective evaporation area (m2) |

0.05 |

0.12 |

0.2 |

0.3 |

0.4 |

0.6 |

|

Condensation area (m2) |

0.03 |

0.1 |

0.15 |

0.2 |

0.25 |

0.3 |

|

Barrel diameter (mm) |

60 |

80 |

100 |

150 |

200 |

300 |

|

Constant pressure feeding funnel volume(L) |

0.25L |

0.5L |

1L |

2L |

3L |

5L |

|

Processing flow (ml/min) |

50 |

100 |

180 |

300 |

500 |

1000 |

|

Motor power (W) |

60 |

80 |

120 |

120 |

120 |

200 |

|

Maximum speed (rpm) |

1100 |

1100 |

1100 |

1100 |

600 |

300 |

Main Features:

1) Low operating pressures

2) Short residence time

3) High evaporation rates

4) Low fouling on evaporator wall

5) Grease-less magnetic sealed bearing, valves and joints

6) Perfect for heat sensitive materials

Vaccum Pump & Water Circulating Bath

1. Low & constant Temp Water Bath

Model : HC-1006

temp range: -10~100℃

temp stability: ±0.05~±0.2℃

resolution: 0.1mm³

tank size: 260*200*140mm³

lifting: 5m

pump flow rate:0~20L/min

tank mouth:180*140mm²

water draining: yes

2. Digital Circulator Heater

Model : GY-30A

temp range: RT+5~200℃

temp stability: ±0.05~±0.2℃

resolution: 0.1mm³

tank size: 400*330*230mm³

tank depth: 230mm

pump flow rate:13L/min

tank mouth:310*280mm²

water draining: yes

3. Constant Tempe Water Bath

Model : GY-15A

temp range: RT+5~200℃

temp stability: ±0.05~±0.2℃

resolution: 0.1mm³

tank size: 300*240*200mm³

tank depth: 200mm

pump flow rate:13L/min

tank mouth:235*160mm²

water draining: no

4. Vacuum Pump

Model: VRD-24

Displacement speed m3/h (L/s):

50Hz, 24 (6.6)

60Hz 28.8 (7.9)

Ultimate partial pressure gas ballast closed : 4x10-2Pa

Ultimate total pressure gas ballast closed : 4x10-1Pa

Ultimate total pressure gas ballast open: 8x10-1Pa

power supply: Single/Three phase

Power rating: 1.1/0.75KW

Intake and exhaust DN (mm): KF25/40

Oil capacity: 1.3~2.0L

Motor speed:

50Hz 1440rpm

60Hz 1720rpm

Ambient temperature: 5 ~ 40°C

Noise level: ≤58dB

Net weight: 35kg

Packaging

We use customized Polywood box or Non-Fumigation Wooden Box to transport instrument as usual.

Shipping

We can ship goods by sea, by air, by train, and smaller goods or spare parts will be shipped by express. You can choose the convenient way.

|

Shipping method |

Note |

|

Express |

Fedex, TNT, DHL, UPS, d oor to door or warehouse to door , very convenient, the carrier will send product to your company |

|

By air |

Airport to airport, yo u need to do the customs clearance and pick up the goods at your local airport |

|

By sea |

Port to port , the cost is much cheaper than express and air, and you need to do the customs clearance and pick-up the goods at your local port |