- Product Details

- {{item.text}}

Quick Details

-

input wire diameter:

-

max 14mm

-

output wire diameter:

-

4-12mm

-

Color:

-

Request

-

power:

-

37.5KW

-

Speed:

-

75 M/MIN

-

Weight:

-

4T, 4T

-

Working type:

-

Fully Automatic

-

loading capacity:

-

1T

-

Certification:

-

ISO

Quick Details

-

Place of Origin:

-

Hebei, China

-

After-sales Service Provided:

-

Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support, Engineers available to service machinery overseas

-

Name:

-

cold drawn rebar making machine

-

input wire diameter:

-

max 14mm

-

output wire diameter:

-

4-12mm

-

Color:

-

Request

-

power:

-

37.5KW

-

Speed:

-

75 M/MIN

-

Weight:

-

4T, 4T

-

Working type:

-

Fully Automatic

-

loading capacity:

-

1T

-

Certification:

-

ISO

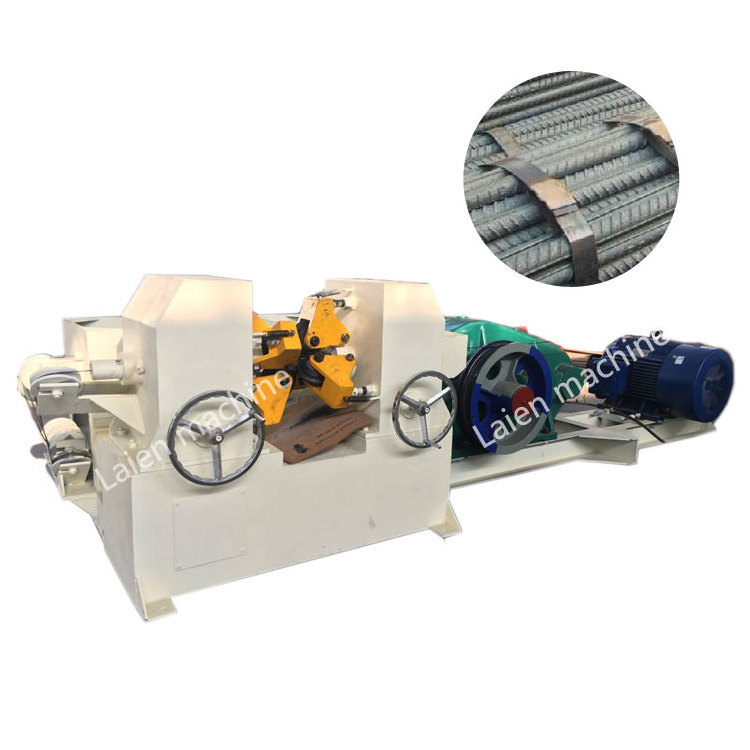

Laien high speed Steel rebar production line three ribbed bar making machine

rebar making machine is a kind of machine use for rolling coil wire from big diameter to small diameter, out put can be ribben type or round type. Input diameter could be special making according your local rod material.

Production flow:

Wire pay-off --- Rust remover ---Scaling and reducing wire machine --- Wire milling machine --- Wire coiling machine --- Finished product rack

|

Item |

Unit |

LE1500T |

LE2000T |

LE3000T |

|

input wire diameter(max) |

mm |

φ13.5 |

φ14 |

Φ16 |

|

output wire diameter |

mm |

Φ4-12 |

Φ4-13 |

Φ4-14 |

|

Power |

KW |

37.5 |

66 |

80 |

|

Rolling speed |

m/min |

75 |

120 |

150 |

|

Cutting length |

m |

1.5-12 |

1.5-12 |

1.5-12 |

|

Motor of flying shear |

KW |

5.5 |

7.5 |

15 |

|

weight |

T |

4 |

6 |

7.5 |

|

loading capacity |

T |

1 |

1 |

2 |

A. The reducer adopts the international reducer, which has large torque, low noise and strong durability.

B. The double-side reel is coated with cemented carbide or wear-resistant material.

C. Adopting the most advanced frequency conversion or electromagnetic technology in the world, it can save 40-60% of electricity, the lowest power consumption per ton is 8-10 degrees, the line speed can reach 90-230 meters per minute, and the production efficiency is improved by more than 40%. Protection of power transmission and transformation systems and electrical equipment is not damaged, which can greatly extend the service life of the machine.

D. rolling the shell body is cast with 45# pure steel, never cracking (Note: other manufacturers cast iron casting). The rolling mill turbine structure is integrated into one, and it is cast in 45# pure steel. It has no components, large pulling force, wear resistance, continuous teeth and durability.

E. bracket with cast steel adjustable bracket