Square gyratory screen machine is also called reciprocating square swing screen, reciprocating square swing screen will be the vibration force generated by the driving device of the 1 around the fixed axis, the direction of a certain rule of change of inertia force, its essence is formed by the eccentric wheel around the fixed axis of rotation of the reciprocating inertia force. According to the structural characteristics and working principle of the swing screen, the screen surface is generally horizontal or slightly inclined arrangement (inclination angle is 0 ° ~ 5 °).

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

DAHAN

-

Voltage:

-

380V/Customized

-

Weight:

-

800 KG

-

Product name:

-

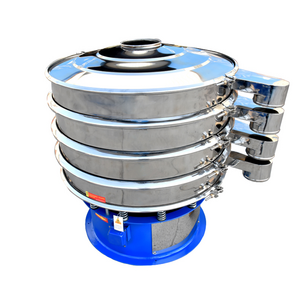

Square gyratory screen machine

-

Keyword:

-

Sand Screening Vibration Machine

-

Function:

-

Screening\separation\sorting\sieving

-

Cleaning system:

-

Bouncing Ball Cleaning System

-

After-sales Service Provided:

-

Online Support

-

Applicable Material:

-

Ore Mining

-

Machine type:

-

Vibrating Screening Sifting Machine

-

Advantage:

-

High Efficiency

-

Customized:

-

Acceptable

Quick Details

-

Type:

-

LINEAR

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DAHAN

-

Voltage:

-

380V/Customized

-

Weight:

-

800 KG

-

Product name:

-

Square gyratory screen machine

-

Keyword:

-

Sand Screening Vibration Machine

-

Function:

-

Screening\separation\sorting\sieving

-

Cleaning system:

-

Bouncing Ball Cleaning System

-

After-sales Service Provided:

-

Online Support

-

Applicable Material:

-

Ore Mining

-

Machine type:

-

Vibrating Screening Sifting Machine

-

Advantage:

-

High Efficiency

-

Customized:

-

Acceptable

Product Description

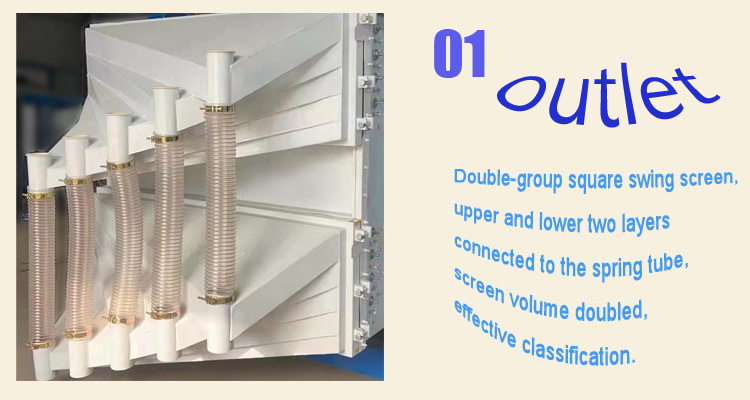

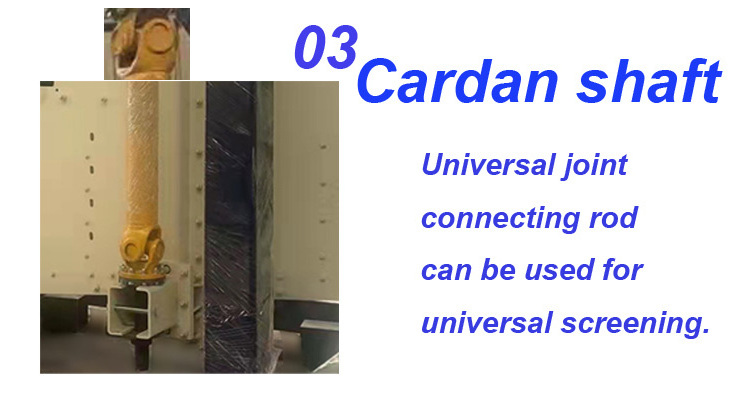

Detail Show

Product Feature

1. Large screening capacity, multi-layer classification design, one machine is divided

into two groups, one machine is used for more than one machine, and the output is doubled.

2. Combination of circular, elliptical, linear three kinds of motion, screening effect

is good. Suitable for a variety of materials screening. High penetration rate and high precision.

3. Fully enclosed structure, dust does not fly, sieve machine vibration is small, low

noise.

4. Flexible screening, acceleration is 4- 5 times lower than ordinary vibrating screen,

and the service life is improved, thereby reducing maintenance costs.

5. Automatic tensioning and automatic cleaning screen installation system, high

utilization rate of screen, long service life, simple and quick net replacement structure.

into two groups, one machine is used for more than one machine, and the output is doubled.

2. Combination of circular, elliptical, linear three kinds of motion, screening effect

is good. Suitable for a variety of materials screening. High penetration rate and high precision.

3. Fully enclosed structure, dust does not fly, sieve machine vibration is small, low

noise.

4. Flexible screening, acceleration is 4- 5 times lower than ordinary vibrating screen,

and the service life is improved, thereby reducing maintenance costs.

5. Automatic tensioning and automatic cleaning screen installation system, high

utilization rate of screen, long service life, simple and quick net replacement structure.

Working principle

After the square gyratory screen is started, the shaking body of the screen machine, that is, the screen box, moves back and forth under the action of inertial force, and the screen box drives the screen surface to shake periodically, so that the materials on the screen surface 1 with the screen box-making directional jumping movement. During this period, the material smaller than the screen surface aperture falls to the lower layer through the screen aperture and becomes the material under the screen. The material larger than the screen surface aperture is discharged from the discharge port after continuous tumbling and jumping movement, thus completing the screening work.

Technical parameters

|

Model

|

Screening Area(m²)

|

Power(kw)

|

Inclined Angle(°)

|

Layers

|

Rotation Frequency(r/min)

|

Distance Range(mm)

|

|

FYBS1030

|

3

|

3

|

5~8

|

1~10

|

180~260

|

25~60

|

|

FYBS1036

|

3.6

|

3

|

5~8

|

1~10

|

180~260

|

25~60

|

|

FYBS1230

|

3

|

4

|

5~8

|

1~10

|

180~260

|

25~60

|

|

FYBS1236

|

4.32

|

4

|

5~8

|

1~10

|

180~260

|

25~60

|

|

FYBS1530

|

4.5

|

5.5

|

5~8

|

1~10

|

180~260

|

25~60

|

|

FYBS1536

|

5.4

|

5.5

|

5~8

|

1~10

|

180~260

|

25~60

|

|

FYBS1830

|

5.4

|

7.5

|

5~8

|

1~10

|

180~260

|

25~60

|

|

FYBS1836

|

6.48

|

7.5

|

5~8

|

1~10

|

180~260

|

25~60

|

|

FYBS2040

|

8

|

15

|

5~8

|

1~10

|

180~260

|

25~60

|

Application Industry

Hot Searches