- Product Details

- {{item.text}}

Quick Details

-

MgO Content (%):

-

0.5%max.

-

CaO Content (%):

-

0.5%max.

-

P2O5 Content (%):

-

0.50%max.

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Huatuo

-

Model Number:

-

YB/T115-2004

-

Purity:

-

5N

-

K2O+Na2O:

-

1.0%max.

-

NaOH:

-

1.0%max.

-

Color:

-

Grey White

-

CAS NO.:

-

69012-64-2

-

PH Value:

-

4.5-7

-

Certificate:

-

ISO 9001:2008

-

Moisture:

-

3%max

-

LOI:

-

6%max

-

Density:

-

300-400 KG/m3

Quick Details

-

SiO2 Content (%):

-

85%~95%

-

Fe2O3 Content (%):

-

1.0%max.

-

Al2O3 Content (%):

-

1.0%max.

-

MgO Content (%):

-

0.5%max.

-

CaO Content (%):

-

0.5%max.

-

P2O5 Content (%):

-

0.50%max.

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Huatuo

-

Model Number:

-

YB/T115-2004

-

Purity:

-

5N

-

K2O+Na2O:

-

1.0%max.

-

NaOH:

-

1.0%max.

-

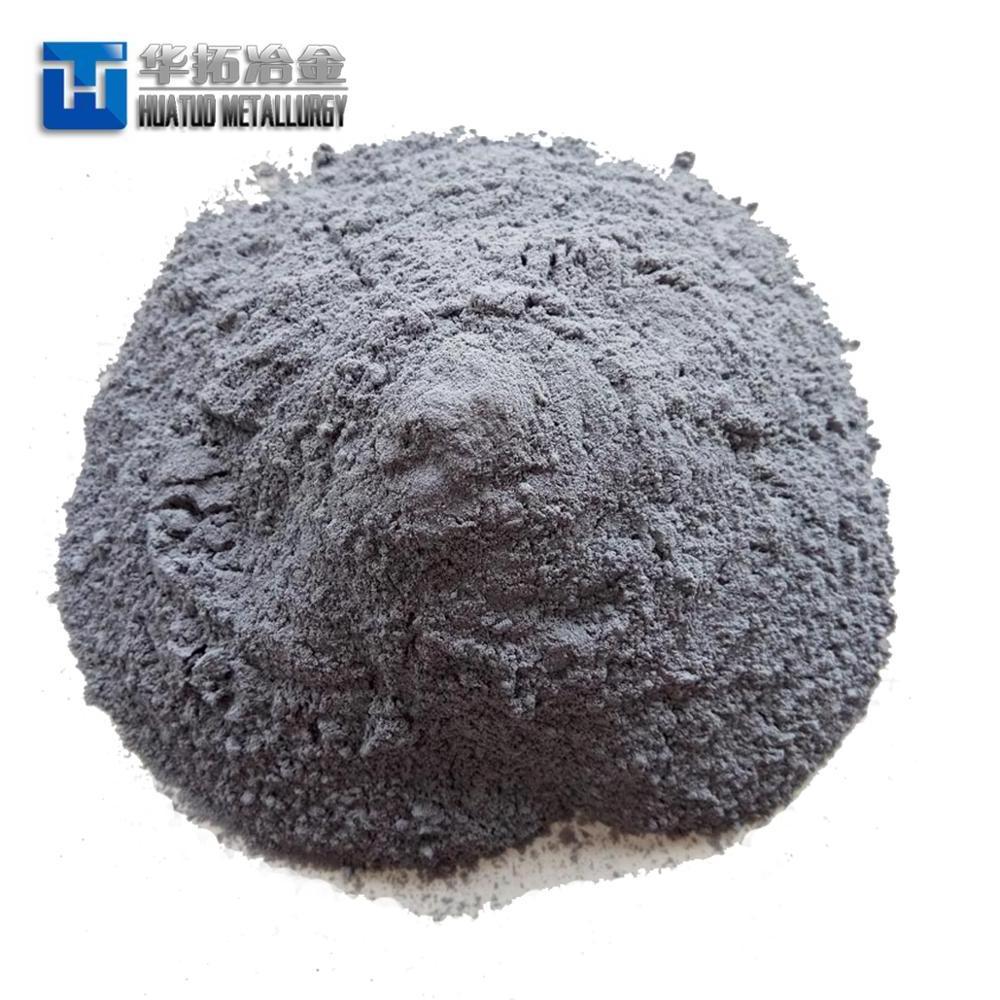

Color:

-

Grey White

-

CAS NO.:

-

69012-64-2

-

PH Value:

-

4.5-7

-

Certificate:

-

ISO 9001:2008

-

Moisture:

-

3%max

-

LOI:

-

6%max

-

Density:

-

300-400 KG/m3

Gray Quartz Sand/Micro Silica Cheap Price

Micro silica (scientific name "silica fume," siilcon ash or Silica Fume), in the smelting of ferrosilicon and industrial silicon, silicon through the flue gas emitted by steam oxidation, the specially designed filter collected the amorphous powder like silica (SiO 2).Microsilica fume average 0.1-0.15 μ m in diameter, the size of several cement average 1.0%. Surface area for the 15-27 m 2 / g, with strong surface activity.

When it is used in concrete, it acts as a filler and as a cementitious material. The small microsilica particles fill spaces

between cement particles and between the cement past matrix and aggregate particles. Microsilica also combines with calcium

hydroxide to form additional calcium hydrate through the pozzolanic reaction. Both of these actions result in a denser, stronger

and less permeable material.

Microsilica's benefits

Dense castables

Improved flow

Hot strength

Strength during heat-up

Areas of application

Steel and foundry: Blast furnace troughs and runners, ladle linings, sliding gates, etc.

Cement: Preheater linings, lining in the chain system and lining of in- and outlet zones of rotary kilns

Glass and ceramics: Kiln furniture

Specification

| Model No. | Analysis Object (%) | ||||||||||||||

| SiO2 | Al2O3 | Fe2O3 | CaO+MgO | K2O+Na2O | C | NaOH | PH | Size above 45um | Moisture | M2/g | |||||

| Min. | Max. | Min. | |||||||||||||

| 97# | 97.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 4.5~6.5 | 3.0 | 1.0 | 15 | ||||

| 94# | 94.0 | 1.0 | 1.0 | 1.5 | 1.5 | 2.0 | 3.0 | 4.5~7.5 | 3.0 | 2.0 | |||||

| 90# | 90.0 | 1.5 | 2.0 | 2.0 | 2.0 | 2.0 | 3.0 | 4.5~7.5 | 5.0 | 2.5 | |||||

| 88# | 88.0 | -- | -- | -- | -- | 2.5 | 4.0 | 4.5~8.5 | 8.0 | 3.0 | |||||

| 85# | 85.0 | -- | -- | -- | -- | 3.0 | 4.5 | 4.5~8.5 | 8.0 | 3.0 | |||||

Practical guidance

Storage

Microsilica is slightly hygroscopic. A slight increase in moisture content is to be expected from production through shipment and

during storage. Normally an equilibrium value in the range of 0.8-1.2% is attained depending on the ambient conditions.

Specific limit values for moisture content is restricted to material condition at the time of delivery, unless otherwise

specified, and tested according to Elkem Standard Test Methods for Microsilica, Test M-1; Water Content.

Dosage

In order to give best results, Elkem Microsilica should be used in quantities of 3-8 wt% of the total dry mix. When optimum

particle packing is applied, the water demand is normally 4 - 5 % of the total dry weight, depending on the microsilica quantity.

Deflocculants

For microsilica to have the desired flow enhancing properties, it is vital that it is well-dispersed. It is generally advised to

use a deflocculant. Among a variety of different additives available, we highly recommend to use SioxX in microsilica containing

castables.

Packaging

1. One ton jumbo bags on pallets in 20" containers

2. Small bags inside ton bags (20kgs, 25kgs, 50kgs per bag)

3. As per customers' requirements

Port of Loading

Tianjin Port & Qingdao Port