- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0

-

CrO Content (%):

-

6 ~ 90, Customizable

-

SiC Content (%):

-

0

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Chrome Corundum Brick

-

Brand Name:

-

YuanDongLi

-

ZrO2 (%):

-

3.5 ~ 5

-

Refractoriness (°C):

-

> 1770 °C

-

Refractoriness (°F):

-

> 3218 °F

-

Refractoriness under Load (0.2Mpa/℃):

-

> 1700 °C

-

Refractoriness under Load (0.2Mpa/°F):

-

> 3092 °F

-

Bulk density (g/cm3):

-

3.30 ~ 3.65 g/cm3

-

Bulk density (lbs/ft3):

-

205.2 ~ 226.9 lbs/ft3

-

Cold Crushing Strength (MPa):

-

>100

-

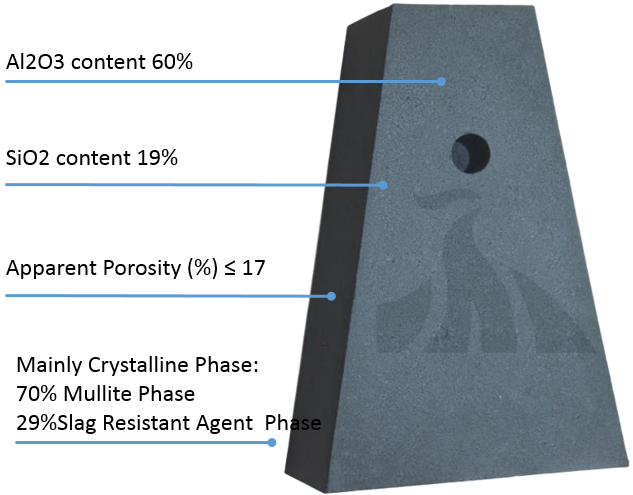

Apparent Porosity (%):

-

17

-

Application:

-

blast furnace, glass kiln, cement kiln and so on

Quick Details

-

SiO2 Content (%):

-

0

-

Al2O3 Content (%):

-

5 ~ 88, Customizable

-

MgO Content (%):

-

0

-

CaO Content (%):

-

0

-

CrO Content (%):

-

6 ~ 90, Customizable

-

SiC Content (%):

-

0

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Chrome Corundum Brick

-

Brand Name:

-

YuanDongLi

-

ZrO2 (%):

-

3.5 ~ 5

-

Refractoriness (°C):

-

> 1770 °C

-

Refractoriness (°F):

-

> 3218 °F

-

Refractoriness under Load (0.2Mpa/℃):

-

> 1700 °C

-

Refractoriness under Load (0.2Mpa/°F):

-

> 3092 °F

-

Bulk density (g/cm3):

-

3.30 ~ 3.65 g/cm3

-

Bulk density (lbs/ft3):

-

205.2 ~ 226.9 lbs/ft3

-

Cold Crushing Strength (MPa):

-

>100

-

Apparent Porosity (%):

-

17

-

Application:

-

blast furnace, glass kiln, cement kiln and so on

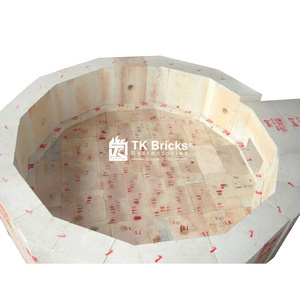

Products Description

Chromium corundum bricks

are mainly used in the flue and rising parts of glass fiber tank kilns, as well as in areas with high erosion of colored (green) glass. Contact glass parts such as tank wall, tank bottom and channel of thermal insulation Glass wool and rock wool fiber furnace. Ceramic frit glaze kiln discharge port. It can also be used for

metallurgical molten pools

and

rotary furnaces

,

Zinc oxide melting furnace

,

Incineration

.

|

Index

|

AC-5

|

AC-10

|

AC-15

|

AC-30

|

AC-50

|

AC-60

|

AC-70

|

AC-80

|

AC-90

|

|

Cr2O3 (%)

|

≥ 5

|

≥ 10

|

≥ 15

|

≥ 30

|

≥ 50

|

≥ 60

|

≥ 70

|

≥ 80

|

≥ 90

|

|

ZrO2 (%)

|

≥ 5

|

≥ 5

|

≥ 5

|

≥ 3.5

|

≥ 5

|

≥ 5

|

≥ 5

|

≥ 3.5

|

≥ 3.5

|

|

Al2O3 (%)

|

≥ 88

|

≥ 84

|

≥ 76

|

≥ 64

|

≥ 43

|

≥ 33

|

≥ 24

|

≥ 15

|

≥ 5

|

|

Bulk Density (g/cm3)

|

≥ 3.20

|

≥ 3.30

|

≥ 3.40

|

≥ 3.45

|

≥ 3.55

|

≥ 3.65

|

≥ 3.75

|

≥ 3.80

|

≥ 3.85

|

|

Bulk Density (lbs/ft3)

|

198.95

|

205.16

|

211.37

|

214.49

|

220.70

|

226.91

|

233.13

|

236.24

|

239.35

|

|

Apparent porosity (%)

|

≤17

|

≤18

|

≤18

|

≤18

|

≤18

|

≤18

|

≤18

|

≤18

|

≤18

|

|

Cold compressive strength (MPa)

|

≥120

|

≥120

|

≥120

|

≥120

|

≥120

|

≥120

|

≥120

|

≥120

|

≥120

|

|

(0.2Mpa,0.6%)Load softening began to temperature °C

|

≥1700

|

≥1700

|

≥1700

|

≥1700

|

≥1700

|

≥1700

|

≥1700

|

≥1700

|

≥1700

|

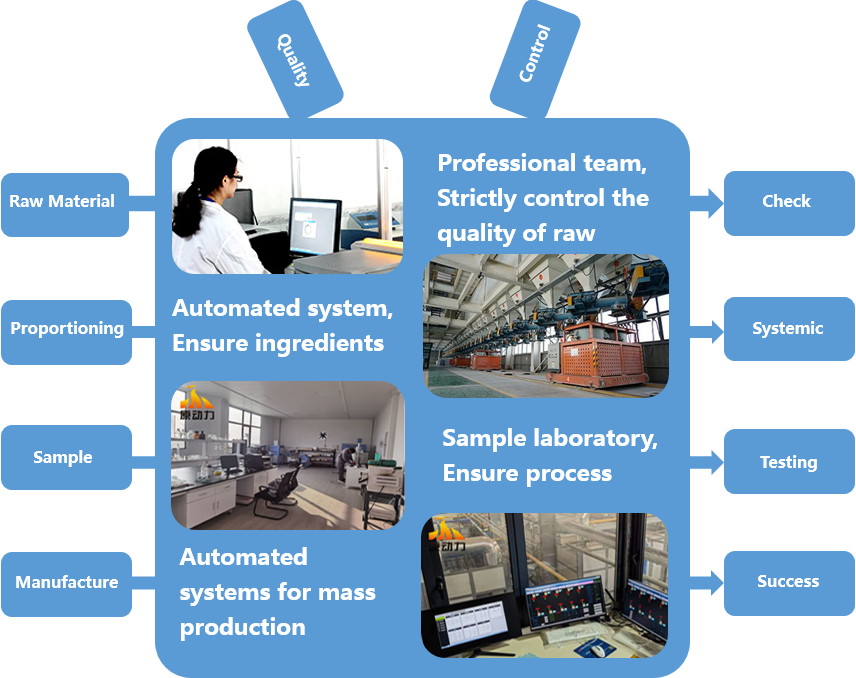

Chrome corundum refractory brick

1.Excellent thermal shock stability

2.Small high temperature creep value

3.Good wear-resistance,slag-resistance and alkali corrosion resistance.

4.High-purity raw material, barely no pollution.

5.High Bulk Density

Shapes and sizes: there are great variety of formats and shapes which are available for different forming and special machine processes.

Chrome corundum brick:

Chrome corundum brick:Using a-Al2O3 as raw material, adding appropriate amount of chromium oxide powder, chrome corundum powder and additives, etc.,after molding, it is fired at a high temperature of 1700 ℃ to form chrome corundum bricks.

Hot Searches