1. Select high-quality materials according to customer requirements, high hardness and good wear resistance;

2. Professional flaw detection equipment testing can effectively guarantee product quality;

3. Excellent workmanship, smooth and flat surface, conducive to providing grinding efficiency;

4. High hardness, good anti-cracking, fine product precision;

5. Perform flaw detection and inspection on the force surface before leaving the factory.

6. Customized production according to customer's drawing requirements.

- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Vertical Grinding Roller Sleeves

-

Diameter interval:

-

60mm-3500mm

-

Color:

-

Customer Requirement

-

Spare parts:

-

ocker arm,roller shell,sealing set etc

-

Quality:

-

High Level

-

Price:

-

Negotiatable

-

Factory Visit:

-

Welcomed Warmly

-

Certification:

-

ISO

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

YINGYONG

-

Weight:

-

50000 KG

-

Product name:

-

Vertical Grinding Roller Sleeves

-

Diameter interval:

-

60mm-3500mm

-

Color:

-

Customer Requirement

-

Spare parts:

-

ocker arm,roller shell,sealing set etc

-

Quality:

-

High Level

-

Price:

-

Negotiatable

-

Factory Visit:

-

Welcomed Warmly

-

Certification:

-

ISO

Product Description

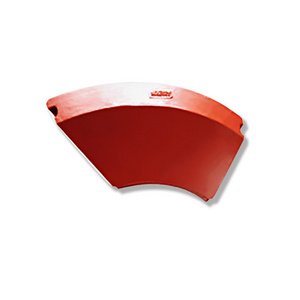

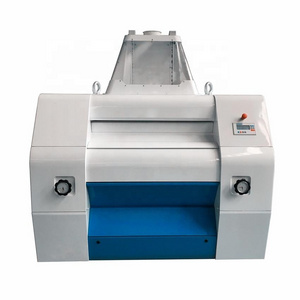

Grinding roller is the main grinding device of vertical grinding. It is mainly divided into conical grinding roller and tire-shaped grinding roller. Shanghai Yingyong Company can provide customized production according to different processing requirements and drawing requirements of customers. In addition, it can also provide finished roll manufacturing services such as casting, precision machining, and flaw detection for grinding rollers.

|

Core Components

|

vertical mill

|

|

Place of Origin

|

shanghai, China

|

|

Dimension(L*W*H)

|

According to capacity

|

|

Product name

|

Vertical grinding milling machine parts roller assembly

|

|

Spare Parts

|

rocker arm,roller shell,sealing set etc

|

|

After Warranty Service

|

Video technical support, Online support, Spare parts

|

|

price

|

negotiability

|

Processing and manufacturing strength

We have several sets of hobbing machines with a diameter of 3m-10m; several sets of various submerged arc welding machines; we have processing equipment such as heat treatment electric furnaces and CNC vertical lathes and CNC lathes, with mechanical

performance testing, impact testing machines, UT and MT flaw detection equipment Complete testing system

performance testing, impact testing machines, UT and MT flaw detection equipment Complete testing system

Production Process Introduction

Making wooden molds, modeling, smelting and pouring, heat preservation, pit clearing, heat treatment, roughing, finishing,inspection, and delivery

Product Display

Quality Control

Product quality inspection

1. Before machining, control the dimensions according to the tolerance casting; ensure the precise control of the internal quality of the casting;

2. During processing, the inspection of the bearing surface is carried out. The main inspection techniques are: ultrasonic inspection (UT), magnetic particle inspection (MT), and color inspection (PT). As a whole, it can reach level three flaw detection, and key parts can reach level two flaw detection; improve the stress capacity and wear resistance.

3. After processing, strict inspection before leaving the factory to ensure the hardness and abrasion resistance of the vertical rollers, sand blasting equipment effectively assists and improves the surface quality.

2. During processing, the inspection of the bearing surface is carried out. The main inspection techniques are: ultrasonic inspection (UT), magnetic particle inspection (MT), and color inspection (PT). As a whole, it can reach level three flaw detection, and key parts can reach level two flaw detection; improve the stress capacity and wear resistance.

3. After processing, strict inspection before leaving the factory to ensure the hardness and abrasion resistance of the vertical rollers, sand blasting equipment effectively assists and improves the surface quality.

Company Introduction

Our Business

Customer Visiting

After-sales service

Delivery provides a full set of test reports, material certificates, certifications, etc., and provides technical guidance installation services.

FAQ

Hot Searches