- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2440*2080*2890MM

-

Voltage:

-

380V

-

Power:

-

0.22kw

-

Weight (KG):

-

4200

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

type:

-

biochar charcoal making machine

-

capacity:

-

2.5-3t/day

-

power:

-

none

-

advantage:

-

no pollution

-

raw material:

-

wood ,hard shells, sawdust briquettes etc

-

warranty time:

-

one year

-

operation:

-

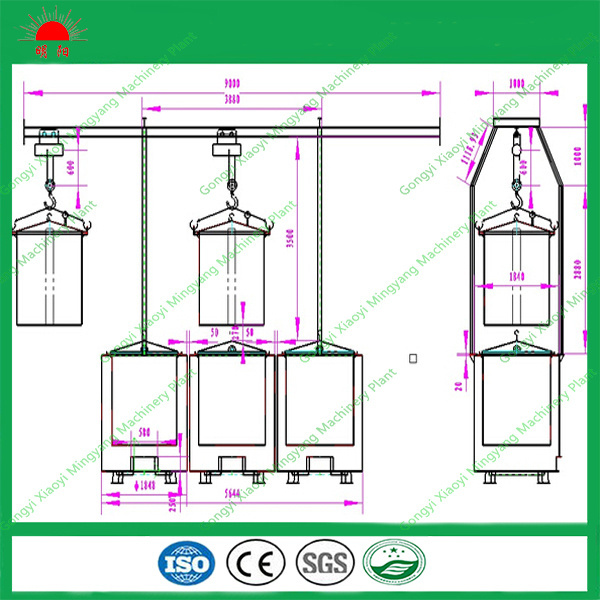

supply hoist equipment

-

certification:

-

ISO and CE

-

service life:

-

more than 5 years

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Mingyang

-

Effective Volume:

-

3 CBM

-

Dimension(L*W*H):

-

2440*2080*2890MM

-

Voltage:

-

380V

-

Power:

-

0.22kw

-

Weight (KG):

-

4200

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

type:

-

biochar charcoal making machine

-

capacity:

-

2.5-3t/day

-

power:

-

none

-

advantage:

-

no pollution

-

raw material:

-

wood ,hard shells, sawdust briquettes etc

-

warranty time:

-

one year

-

operation:

-

supply hoist equipment

-

certification:

-

ISO and CE

-

service life:

-

more than 5 years

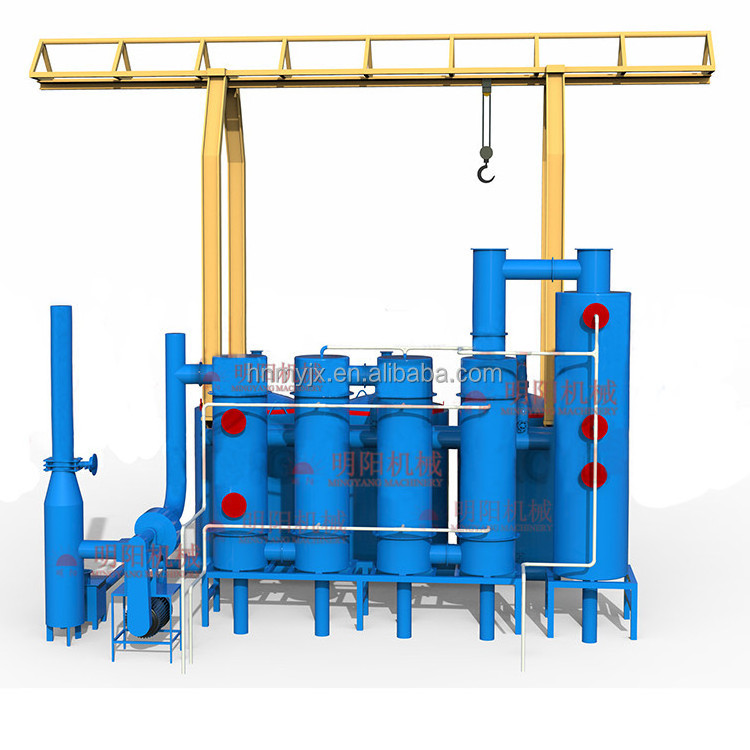

Factory plant sale environment friendly biochar making machine/ retorting biochar charcoal machine

The photos of the client visited our plant :

We are China professional charcoal making machines manufactuer with more than 30 years history . we believe that we can give you the most suitable machines with our best service .

Charcoals from the biochar charcoal making machine

INTRODUCTION of the biochar charcoal making machine

1,The whole gas flow type include the outer stove, three set of inner stoves , and the 3ton hoisting tools.

2,When one inner stove have been finished carbonization, we will use the hoisting tools hoist the inner stove from the outer stove, then let the inner stove natural cooling, at the same time, we can put another inner stove into the outer stove, which will save a lot of cooling time, so the productivity effect increase a lot, it is the ideal choice for mass production of charcoal.

FEATURES of the biochar charcoal making machine

1,Easy operate and maintain, higher safety, energy saving

2,High carbonization rate, no smoking, little pollution,

3,Newly developed carbonization stove, which can dry the materials with the superfluous energy produced in the process of carbonization. 6-8 hours per stove and can work continuously

4,the tube of fume extraction will recycle the gas flow which come from the inner stove during the carbonizing process for continue warming the stove, and it will save 70% energy consumption and recycle 95% smoking

ENVIRONMENT of the biochar charcoal making machine

1,Totally No pollution ( there are two reasons : the frog and the gas flow will be recycle from the smoke recycle device and use for heating the kiln again

2. We install a special device that can use the liquid gas as the energy to heating the carbonization kiln, and it will not produce any smoke.

all the models of the biochar charcoal making machine in our plant :

| model | capacity | inner volume | temperature | machine include |

| QHL-1 | 1.5-2t/24h | 2.75*3 | 400-600degree |

1outer stove, 3inner stoves with 3 caps, 1 3ton lifting device,

1smoking tank |

| QHL-2 | 3-4t/24h | 2.75*6 | 400-600 degree |

2 outer stove, 6 inner stoves with 6 caps, one 5-ton hoisting

equipment with e-motor, 1smoking tank |

| QHL-3 | 4.5-6t/24h | 2.75*9 | 400-600 degree |

3 outer stove, 9 inner stoves with 9caps, one 5-ton hoisting

equipment with e-motor, 1smoking tank |

| QHL-4 | 6-8t/24h | 2.75*12 | 400-600 degree |

4 outer stove, 12 inner stoves with 12caps, one 5-ton hoisting

equipment with e-motor, 4smoking tank |

|

Model No. |

QHL |

DESCRIPTION |

biochar charcoal making machine |

|

TECHNICAL DATAS & FEATURES |

|||

|

power |

exhaust fan (0.22kw, 2 phase,used for discharge the moisture

|

||

|

raw material could be |

wood ,coconut shell, wood briquette, bamboo, almond shell, plam shell, |

||

|

final product |

wood charcoal , coconut shell charcoal and so on |

||

|

capacity |

wood (6- 8ton/24hour) wood briquette (9-10ton/24hours),coconut shell (7-8ton/24hours) |

||

|

operation |

one people one shift ( one day two shift) |

||

|

carbonization time |

wood log ( 8-10hours). Wood briquette (8hours), coconut shell (6hours) |

||

|

energy consumption |

20-30kg firewood or 15kg liquid gas .This type will save 30% payment |

||

|

The stove include |

3 outer stove,9 inner stoves,3smoking recycle tube, 3 purification tank, 1 five-ton hoisting equipment with E-hoist |

||

|

introduction of the parts |

outer stove |

includes heating room (for heating the stove), furnace body and heat-keeping layer (it is made of the heat insulating material, used for keep the heating)

|

|

|

inner stove |

Consist of the stove tank body and the sealed top cap. Both of them are made of the heat resistance thermal steel. , and the three carbonization basket can be stack together, easy for loading and transporting ,and it will save a lot of space and transport charge.

|

||

|

smoking recycle tube |

When during the process of carbonizing, there will be some smoke.( can be burning) the smoke can return to the furnace through tube for purifying, after purification , the combustible smoking can be flow into the heating room of the outer stove for heating the stove again, |

||

|

purification tank |

This system is consisting of purification tank and the exhaust-heated cycle pipe. And Smoking purification tank are used for purify the smoking (can not Burning) and filter thewood tar. The smoking through the purification tank will Become water vapor, and it will not pollute the air.

|

||

|

hoisting equipment |

it include the steel hoisting frame and the E-hoist .And it is easy for loading and unloading the stove, and can reduce labor intensity, and it can be avoid the high-temperature burn when lift the carbonization basket

|

||

|

P.S.: 1. three inner stoves to recycle 2. 0.8-1MT/stove inside volume:1.8-2.0M 3 3. Carbonizing time:6-8hours Cooling type: Natural cooling or forced cooling Cooling time:8-12(natural cooling)

|

|||