- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

XKJ

-

Dimension(L*W*H):

-

875*1090*950

-

Weight:

-

1000 KG

-

Warranty:

-

12 month

-

Product name:

-

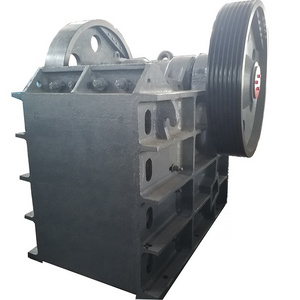

150x250 stone jaw crusher

-

Max Feeding Size:

-

125mm

-

Adjustable range of discharging:

-

10-40mm

-

Main Shaft RPM:

-

300r/m

-

Color:

-

as per your demand

-

Installation:

-

under technician guidance

-

Price:

-

Negotiable

-

Market:

-

Africa,Europe,Asia,etc

-

Running Cost:

-

Low

Quick Details

-

Application:

-

Rock Crushing, Stone Crushing

-

Capacity(t/h):

-

1-4t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

XKJ

-

Dimension(L*W*H):

-

875*1090*950

-

Weight:

-

1000 KG

-

Warranty:

-

12 month

-

Product name:

-

150x250 stone jaw crusher

-

Max Feeding Size:

-

125mm

-

Adjustable range of discharging:

-

10-40mm

-

Main Shaft RPM:

-

300r/m

-

Color:

-

as per your demand

-

Installation:

-

under technician guidance

-

Price:

-

Negotiable

-

Market:

-

Africa,Europe,Asia,etc

-

Running Cost:

-

Low

Brief Introduction of jaw crusher:

The jaw crusher of the Henan Xingyang Mining Machinery Manufactory offers is ideal for primary and secondary crushing. Jaw Crusher is one of the main types of primary crushers in a mine or ore crushing process plant and also is one of the most widely used crushing equipment in mining industry. XKJ is a famous jaw crusher manufacturer in China, and sold crusher machines to all over the world. This series of jaw crusher can reach the crushing ratio of 4-6 and the shape of final product is even. Because it is primary crusher, Jaw crusher is designed for long life service with minimum maintenance for hard, tough, abrasive material and overload high capacity.

Application:

The jaw crushers are widely used in mining, building materials, chemical industry, and metallurgy and so on. It is suitable for primary and secondary crushing for all and rocks with compressive strength less than 320 MPa. In construction, road and railway building, construction and other industries are widely applied to crush high hardness, mid hardness and soft rocks and ores such as slags, construction materials, marble, etc.

Mechanism composition:

Strong jaw crusher is main part of the main frame, partiality axis rotation part, crushing cavity working part, insurance device, discharging mouth adjusting devices components, etc.

1, Frame part: the board, former box, back box welding components, etc.

2, Eccentric shaft rotational part: mainly by dynamic jaw, eccentric shaft, bearing, housing, pulley etc. Which is the main part of the power transmission.

3, Crushing cavity working part: mainly by set jaw plate, dynamic jaw plate, side lining board, guard board and other components, which is broken material working parts.

4, Insurance device: by cubits board, cubits, spring, spring board a lever and other components, which is abnormal cases on the auto-balance insurance effect parts.

5, Discharging mouth adjusting device: this device used to adjust the size of discharging mouth size, control the grain-size. Mainly by the adjustment of fixed inclined, adjust the sliding block, top inclined silk bolt, the slider lock bars etc.

Performance characteristics:

1, unique structure of jaw head, seal guarantee, extend working life of the bearing.

2, integral casting of the bearing base, adopt the new assembly process to perfectly match with the frame, increase the radial intensity.

3, adopting deep cavity "V" type structure, to greaten the feeding size (compared with ordinary jaw crusher) and increase the capacity.

4, adjust the structure of the discharging opening, which is convenient, quick, safe

5, tension bar protection device, more safer

6, increase the bearing capacity of the jaw head, make the machine more efficient, safe, extend the working life of the bearing and main shaft.

7, new oil road design, matched with the oil pump, more simple and efficient on the operation and maintenance.

8, unique flywheel design, effectively reduce the vibration, running more smoothly.

Working Principle of jaw crusher:

1.The Jaw crusher plant price adopts the electric motor as the power.

2.The eccentric shaft is revolved by an electric motor through v-belts.

3.They make the swing jaw to follow the preconcerted path to crush the material.

4.The crushing chamber is composed of the stationary jaw plate, swing jaw plate and the liner plate.

5.The material is discharged from the lower part of machine.

Packing: Standard export containers,bare main machine,motors and small parts are packed in wooden cases.

|

Model |

Feed Opening (mm) |

Max. feeding size (mm) |

Adjusting range of discharge opening (mm) |

Capacity (t/h) |

Rotation speed of eccentric shaft (r/min) |

Motor powe r (kw) |

Total weight (t) |

Dimensions (L*W*H)(mm) |

|

PE-150*250 |

150*250 |

125 |

10-40 |

1-3 |

250 |

5.5 |

0.8 |

720*660*850 |

|

PE-200*300 |

200*300 |

180 |

15-50 |

2-6 |

260 |

7.5 |

1.2 |

910*750*990 |

|

PE-200*350 |

200*350 |

180 |

18-70 |

3-10 |

260 |

11 |

1.5 |

1000*870*990 |

|

PE-250*400 |

250*400 |

210 |

20-60 |

5-20 |

300 |

15 |

2.8 |

1300*1090*1270 |

|

PE-400*600 |

400*600 |

340 |

40-100 |

16-60 |

275 |

30 |

7 |

1730*1730*1630 |

|

PE-500*750 |

500*750 |

425 |

50-100 |

40-110 |

275 |

55 |

12 |

1980*2080*1870 |

|

PE-600*750 |

600*750 |

500 |

150-200 |

80-240 |

275 |

55 |

15.8 |

2070*2000*1920 |

|

PE-600*900 |

600*900 |

500 |

65-160 |

50-180 |

250 |

55 |

17 |

2190*2206*2300 |

|

PE-750*1060 |

750*1060 |

630 |

80-140 |

110-320 |

250 |

110 |

29 |

2660*2430*2800 |

|

PE-800*1060 |

800*1060 |

640 |

130-190 |

130-330 |

250 |

110 |

29.8 |

2710*2430*2800 |

1.Design most suitbale flow chart and layout freely according to your request.

2.Provide operating instruction and relative drawing.

3.We can send 1-2 technicians to the site for guiding the installation and commissioning.

4.We offer training service for free.

5.We offer the components with favorable price.

6.Lifetime Warranty.