- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

JUBAO

-

Voltage:

-

110-480V or customized

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

50 KG

-

Product name:

-

Dia 1800 mm Food processing industry Tumbler sieve machine

-

Keyword:

-

tumbler sieve

-

Material:

-

Stainless steel304/316L, Q235

-

Layer(s):

-

1-5 Layers

-

Color:

-

Customers' Request

-

Function:

-

Screening\separation\sorting\sieving

-

Cleaning system:

-

Bouncing ball/rotary brush/ultrasonic system

-

Mesh size:

-

2-635

-

Surface treatment:

-

Mirror Polishing/brushed/sandblast/painted

-

Motor type:

-

Single Vibrating Motor

Quick Details

-

Type:

-

Circular

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

JUBAO

-

Voltage:

-

110-480V or customized

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

50 KG

-

Product name:

-

Dia 1800 mm Food processing industry Tumbler sieve machine

-

Keyword:

-

tumbler sieve

-

Material:

-

Stainless steel304/316L, Q235

-

Layer(s):

-

1-5 Layers

-

Color:

-

Customers' Request

-

Function:

-

Screening\separation\sorting\sieving

-

Cleaning system:

-

Bouncing ball/rotary brush/ultrasonic system

-

Mesh size:

-

2-635

-

Surface treatment:

-

Mirror Polishing/brushed/sandblast/painted

-

Motor type:

-

Single Vibrating Motor

Dia 1800 mm Food processing industry Tumbler sieve machine is a kind of large output and high efficiency powder particle material screening equipment. It is used for scarlping, impurity and filter all kinds of material. It's material can be carbon steel and stainles .

working principle: tumbler sieving machine imitate manual screening principle and use the elliptical motion to aid in screening of even very fine material. The fine particle will move toward the center and the larger go to the outside. It allows the material stay on the screen surface so that they can get efficient screening

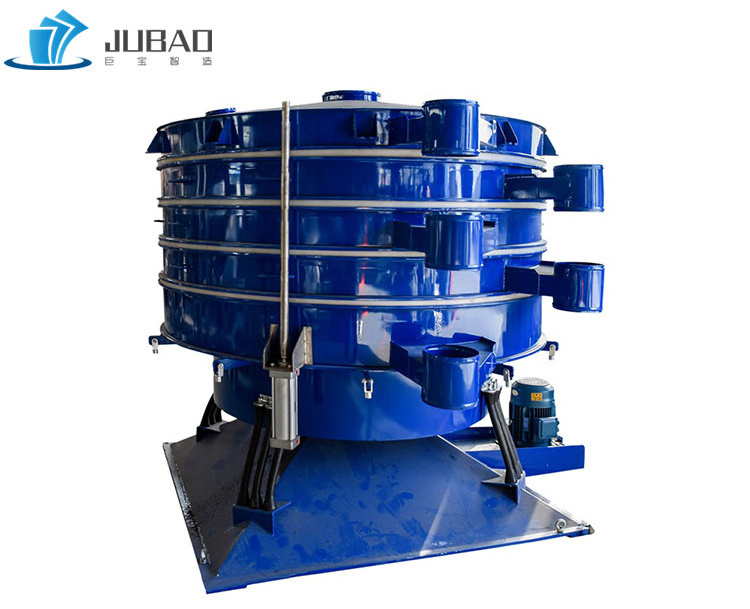

You can learn about the outter structures and apperance of the tumbler screeners s from the picture.

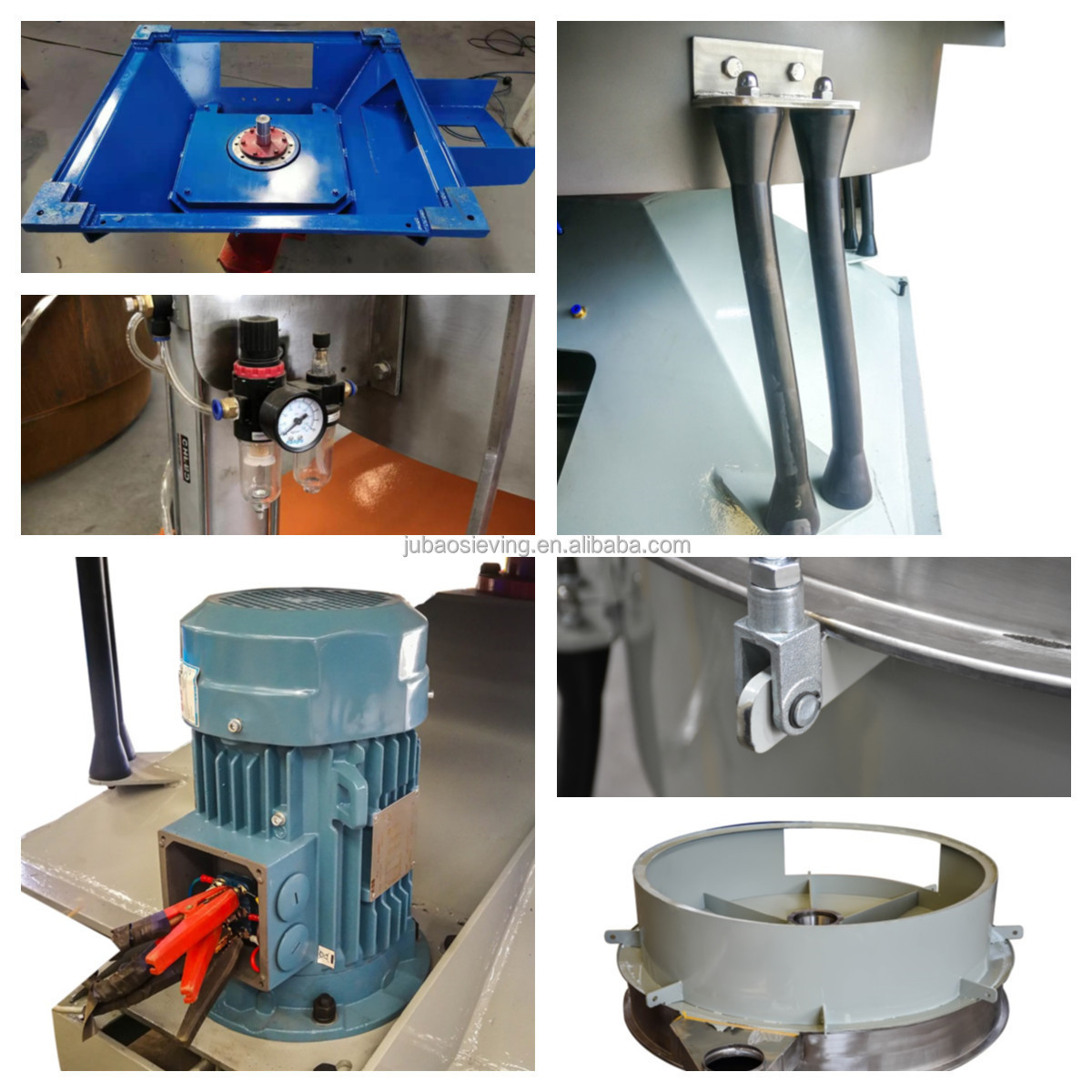

The components photo

Tumbler sieve process

It is suitable the material like ball,column, flake and irregular and easy to plug fine screening.

|

Model |

BY1000 |

BY1200 |

BY1600 |

BY1800 |

BY2000 |

BY2600 |

|

Diameter |

1000mm |

1200mm |

1600mm |

1800mm |

2000mm |

2600mm |

|

Area(M2) |

0.71 |

1.11 |

1.83 |

2.46 |

3.05 |

5.31 |

|

Mesh Size |

0.028mm-12mm |

|||||

|

Layer |

1-3 |

1-5 |

||||

|

Power |

1.5KW |

1.5KW |

3.0KW |

4.0KW |

4.0KW |

5.5KW |

|

Material |

SS: Stainless steel - MS: mild steel |

|||||

|

Feeding material size |

0-20mm |

|||||

|

Product sort size variety |

2-5 different sized product |

|||||

|

Screen motion |

Three dimensional: Eccentric, Radial and Tangent |

|||||

|

Net Cleaning |

Bouncing ball,Ultrasonic device,Rolling brush |

|||||

|

Leakage proof design |

100% full enclose dust proof |

|||||

|

Remark: we can custom feeding port, discharging port |

||||||

The machines rae wrapped in film firstly, and the machines of small size are put into wooden cases while super large machines without the cases.The delivery for 7Woriking Days after receiving the payment.