- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

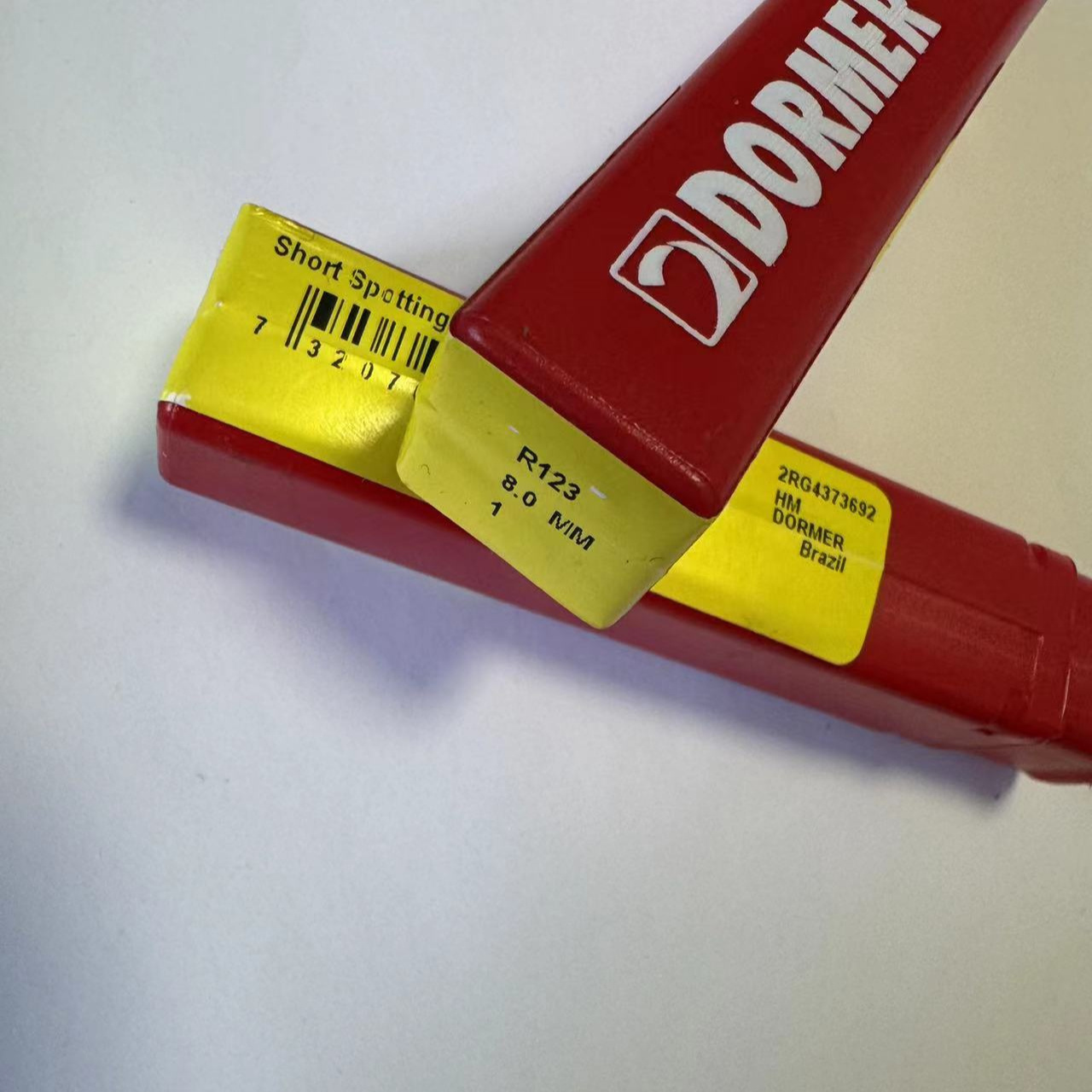

DORMER

-

Model Number:

-

R123 8.0 MM 1

-

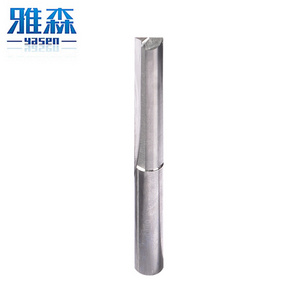

Product name:

-

bit

Quick Details

-

Type:

-

bit

-

Use:

-

bit

-

Finish:

-

Other

-

Place of Origin:

-

China

-

Brand Name:

-

DORMER

-

Model Number:

-

R123 8.0 MM 1

-

Product name:

-

bit

1.The problem of broken knives

Impact: Sudden changes in workpiece size or surface finish, resulting in burrs on the sparked surface

Reason: The parameter setting is not suitable, the blade material selection is not suitable, the workpiece rigidity is not good,

and the clamping is unstable.

Measures: Check whether the parameter design is reasonable, and select the corresponding tool according to the workpiece material.

Reason: The parameter setting is not suitable, the blade material selection is not suitable, the workpiece rigidity is not good,

and the clamping is unstable.

Measures: Check whether the parameter design is reasonable, and select the corresponding tool according to the workpiece material.

2.Severe breakage

Impact: Sudden and unpredictable occurrence, resulting in scrapping of tool holders or defective workpieces and

scrapping

Cause: Incorrect design of machining parameters: The vibrating workpiece or insert is not installed in place.

Measures: Set reasonable processing parameters, reduce the feed and reduce the chip selection of the corresponding processing

blade, strengthen the rigidity of the workpiece and the blade.

scrapping

Cause: Incorrect design of machining parameters: The vibrating workpiece or insert is not installed in place.

Measures: Set reasonable processing parameters, reduce the feed and reduce the chip selection of the corresponding processing

blade, strengthen the rigidity of the workpiece and the blade.

3.The flanks are worn

Effects: Workpiece size gradually changes or surface finish decreases

Reason: The linear speed is too high, reaching the tool life

Action: Adjust processing parameters, such as reducing the linear speed and switching to a blade with higher wear resistance

4.Built-up edge

Effects: Inconsistent workpiece size, poor surface finish, pile or burrs attached to the workpiece surface

Reason: Cutting speed too low, underfeed insert/not sharp enough

Action: Increase cutting speed, feed with sharper inserts

1.The problem of broken knives

Impact: Sudden changes in workpiece size or surface finish, resulting in burrs on the sparked surface

Reason: The parameter setting is not suitable, the blade material selection is not suitable, the workpiece rigidity is not good,

and the clamping is unstable.

Measures: Check whether the parameter design is reasonable, and select the corresponding tool according to the workpiece material.

Reason: The parameter setting is not suitable, the blade material selection is not suitable, the workpiece rigidity is not good,

and the clamping is unstable.

Measures: Check whether the parameter design is reasonable, and select the corresponding tool according to the workpiece material.

2.Severe breakage

Impact: Sudden and unpredictable occurrence, resulting in scrapping of tool holders or defective workpieces and

scrapping

Cause: Incorrect design of machining parameters: The vibrating workpiece or insert is not installed in place.

Measures: Set reasonable processing parameters, reduce the feed and reduce the chip selection of the corresponding processing

blade, strengthen the rigidity of the workpiece and the blade.

scrapping

Cause: Incorrect design of machining parameters: The vibrating workpiece or insert is not installed in place.

Measures: Set reasonable processing parameters, reduce the feed and reduce the chip selection of the corresponding processing

blade, strengthen the rigidity of the workpiece and the blade.

3.The flanks are worn

Effects: Workpiece size gradually changes or surface finish decreases

Reason: The linear speed is too high, reaching the tool life

Action: Adjust processing parameters, such as reducing the linear speed and switching to a blade with higher wear resistance

4.Built-up edge

Effects: Inconsistent workpiece size, poor surface finish, pile or burrs attached to the workpiece surface

Reason: Cutting speed too low, underfeed insert/not sharp enough

Action: Increase cutting speed, feed with sharper inserts

Hot Searches