- Product Details

- {{item.text}}

Quick Details

-

Application:

-

grow fodder trays vegetable plant greenhouse

-

Voltage:

-

220V, according to local voltage requirements

-

Power(W):

-

10KW

-

Dimension(L*W*H)::

-

5500*2200*2100MM

-

Certification:

-

CE ISO

-

Character:

-

Much different from market low cost quality machine

-

After-sales Service Provided::

-

Overseas service center available

-

Warranty:

-

1 year/10Years

-

Features:

-

Hydroponic growing system

Quick Details

-

Size:

-

Large

-

Type:

-

Multi-Span Agricultural Greenhouses

-

Place of Origin:

-

Henan, China

-

Application:

-

grow fodder trays vegetable plant greenhouse

-

Voltage:

-

220V, according to local voltage requirements

-

Power(W):

-

10KW

-

Dimension(L*W*H)::

-

5500*2200*2100MM

-

Certification:

-

CE ISO

-

Character:

-

Much different from market low cost quality machine

-

After-sales Service Provided::

-

Overseas service center available

-

Warranty:

-

1 year/10Years

-

Features:

-

Hydroponic growing system

canaleta para hidroponia hydroponic garlic growing system sprinkler irrigation system

Product Description

Introduction:

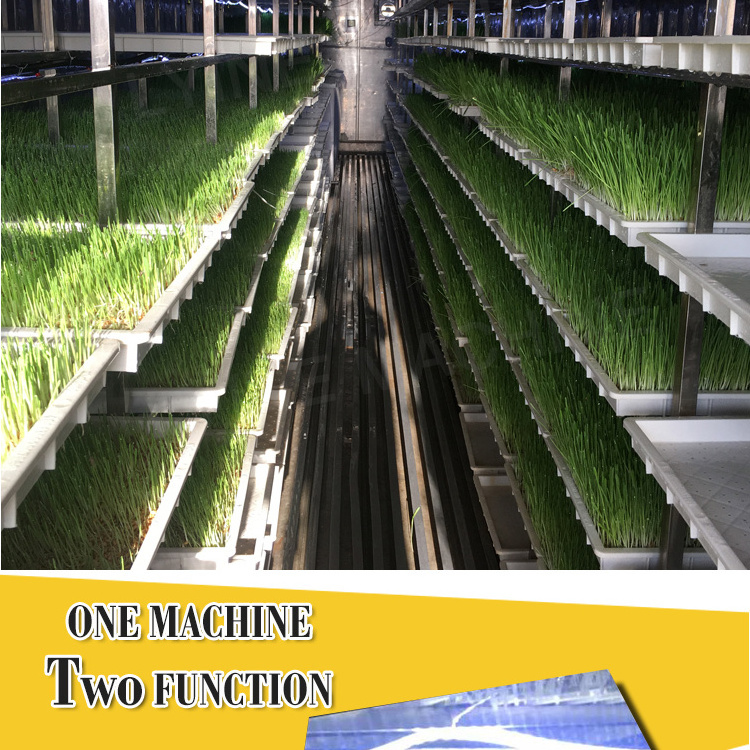

Hydroponic fodder machine is automatically controlled by microcomputer, which is energy-saving and water saving. It is easy to be managed which makes cultivation of green grass in large, small and medium farm (for camels, cattle, horse, deer and sheep ect.) It is a perfect room providing fresh green fodder to animals. 1. The fodder will grow from a dry seed to a 12 -15 cm plant within 4 days. 2. The system can bring down your feed costs by up to 60% and further more 3. You will have guaranteed supply of Green Feed all the 12 months of the year no matter the weather conditions.

Four Type of the Hydroponic fodder machine:

|

Type |

Daily Output |

Weight |

Tray Quantity(PCS) |

Size(L,W,H) |

|

LY DM - 200 |

100 KG |

400KG |

50 |

2.9x1.1x 2 .1m |

|

LY DM - 1000 |

500 KG |

3000KG |

210 |

6.08x2.43x 2 .69m |

|

LY DM - 2000 |

1000 KG |

5000KG |

420 |

12.8x2.45x 2 .9m |

|

LY DM - 3000 |

1500KG |

6000KG |

630 |

12.8 x2.45x 2 .9m |

|

LY DM - 4000 |

20 00KG |

7000KG |

840 |

12.8 x2.45x 2 .9m |

Features

HOW IT WORKS

The principle of a Hydroponic fodder machine is simple:

Day 1: Pre-soaked swollen grains evenly spreading in the plastic tray. Day 2: Seeds have begun to sprout roots and head after soaked for 24 hours. Day 4: Tremendous growth in root bed occurs before growth of shoots/ heads. Healthy root beds will create a m ass that resembles that of a tight knit carpet lifting the seed and shoot from the tray. Day 6: Root bed is almost fully developed and growth transfers to shoots that have grown to 4-6 inches in overall height. Day 7: Feeding Day--Growth so fast you can nearly see it! Fully developed shoots and root bed ready for feeding. Healthy root beds are hard to separate and shoots are 8-10 inches in overall height.

Advantages

The advantages of Hydroponic fodder machine

• 7-day cycle lets you produce nutrient-rich fodder daily for just pennies a pound.

• Water-saving nutrient film technique watering regimen eliminates the need for overhead watering and reduces humidity levels that may promote fungus and mold growth.

• UV-stabilized, NSF-quality PE growing trays are supported by galvanized framing.

• Multi-system control allows you to easily get the amount of fresh animal feed you seek.

Animal feed fodder hydroponic greenhouse system also allows for the exclusion of chemicals like pesticides and herbicides because the plants are in a more protected growing environment making for a totally green and sustainable way to produce feed – an important factor for farmers trying to meet the demands of consumers who are increasingly seeking non-GMO products.

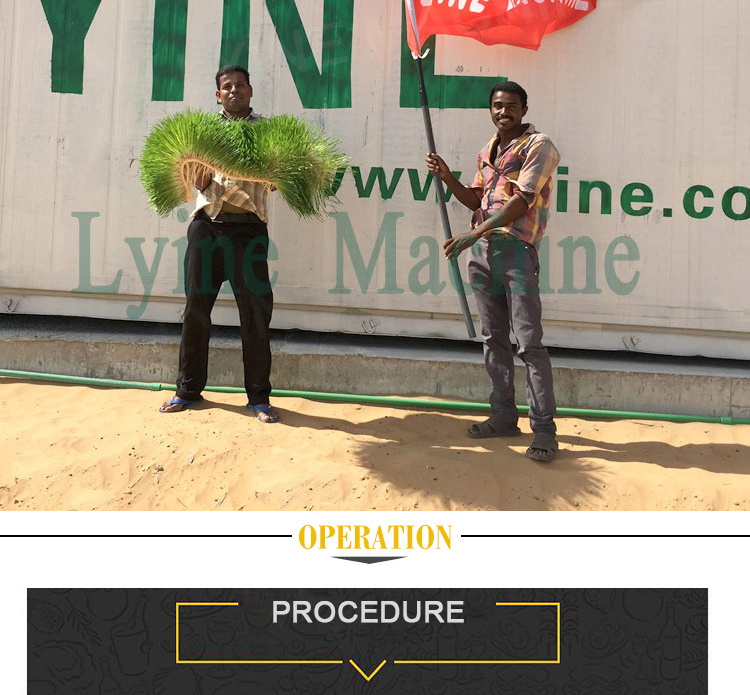

Project show

The Project Shows of the g rass seeds sprouting Hydroponic fodder machine are widely applied in all kind of hydroponic farms all over the world.

Related Products

More Commercial Greenhouse Hydroponics System for Your Choices :

Packaging & Shipping