- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

0.25

-

Key words:

-

wood factory use sharpener tct saw blade grinding machine

-

Angle of grinding blade:

-

±20°

-

Angle of rotation frame:

-

L30°R45°

-

Diameter of saw:

-

80-700mm

-

Dimension:

-

430*430*335mm

-

Stipulation:

-

125*10*32mm

-

Voltage:

-

220v

-

Power:

-

250w

-

Revolution:

-

2850r/min

-

Weight:

-

32kg

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

NEWEEK

-

Weight (KG):

-

32 KG

-

Power (kW):

-

0.25

-

Key words:

-

wood factory use sharpener tct saw blade grinding machine

-

Angle of grinding blade:

-

±20°

-

Angle of rotation frame:

-

L30°R45°

-

Diameter of saw:

-

80-700mm

-

Dimension:

-

430*430*335mm

-

Stipulation:

-

125*10*32mm

-

Voltage:

-

220v

-

Power:

-

250w

-

Revolution:

-

2850r/min

-

Weight:

-

32kg

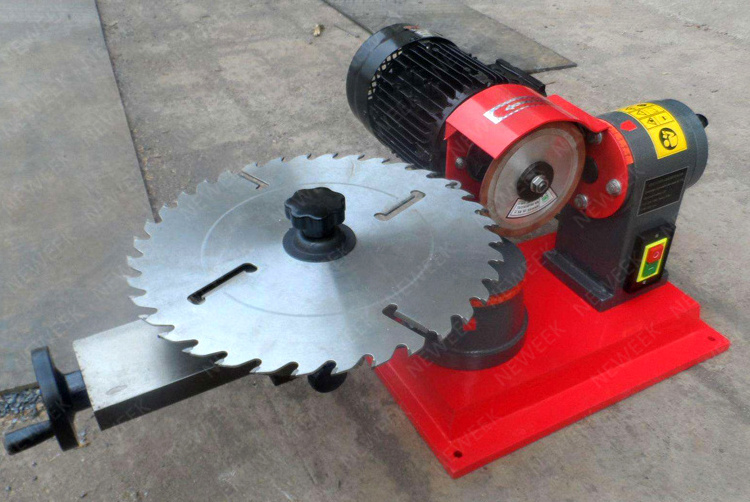

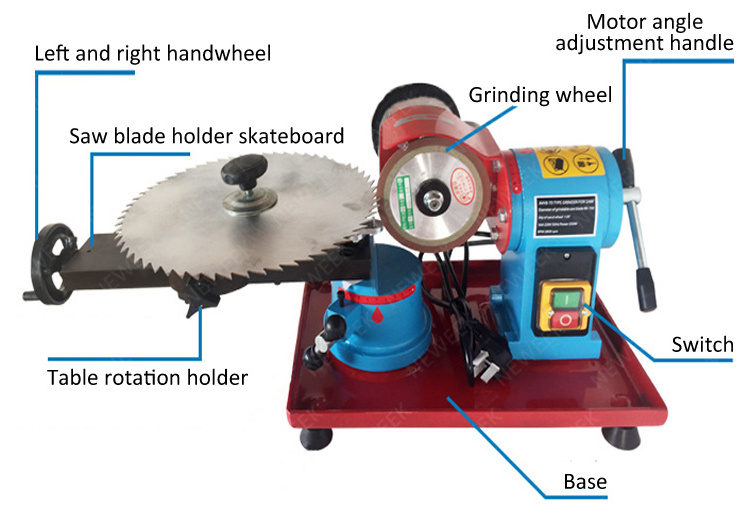

NEWEEK hard alloy wood factory use sharpener tct saw blade grinding machine

1. This machine is designed for grinding carbide saw blades, suit for all kinds of carbide saw blades, it is with adjustable annular pallet, it can maximum hold knob teeth or other grinding parts, with positioning pins, according to the diameter and size of the teeth of the saw blade, adjust to the best position, according to the size of the blade diameter can adjusted the blades in the best position, pallet with rotary table ensured the sharpening original angles or change it.

2. This machine’s worktable with a rotary table, easy to adjust sharpening feed angle.

3. Rotary table with sliders, mandrel, limit screws, both easy to operate, but also to ensure sharpening radius center.

4. Grinding head has positive and negative 20 rotation mechanism, it meet the request of oblique edge blade sharpening.

|

Model |

WM 70 |

125*10*32mm |

|

|

±20° |

Voltage |

220v |

|

|

Angle of rotation frame |

Power |

250 w |

|

|

80-700mm |

|||

|

430*430*335 mm |

Weight |

3 2kg |

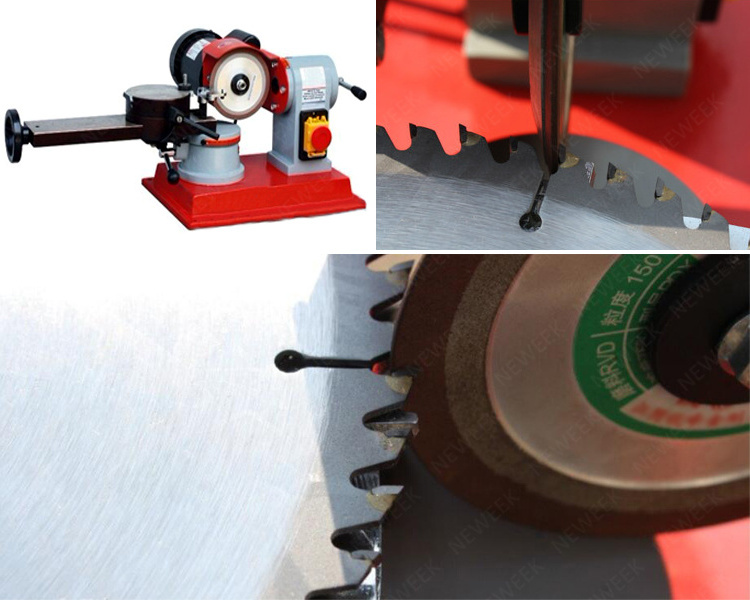

1.Saw on the plate is equipped with rotary table, easy to adjust feed grinding blade Angle.

2.Rotary table with a slider, spindle, such as the limit screw.

3.This machine is convenient operation and ensure.

Method of operation

1. Loosen the surround finder. Adjust the angle of the grinding plate to lock

2. Adjustment of the central axis

- Grind the small saw blade and add the center shaft to the rotating paper side: otherwise, adjust the distance

- Push the center shaft to the right end

- Mount the saw blade, rotate the handwheel, and position the initial serrated surface

- Rotate the rotary table to determine the angle of the serrated surface

- Rotate the table to confirm the feeding angle of the grinding surface. The angle between the general grinding surface and the working surface of the grinding wheel is 5 degrees (visual inspection).

3. Adjustment of positioning combination

Adjust the saw blade to the best sharpening state, rotate the positioning bracket and the positioning plate bracket, adjust the positioning slightly to the appropriate sawtooth root and leave the grinding clearance (custom) to tighten the fixing screws.

4. Adjust the axial direction of the center of gravity to the same amount of grinding clearance as above.

5. After checking that all the parts are fixed, the hand blade should be smoothly fed and ground.

Safety Precautions

1. Meet the voltage standard, good grounding.

2. The machine must be placed in a dry, non-corrosive, stable, horizontal position.

3. Loosen the surrounding pallet and adjust the angle of the grinding disc.

4. Lock all locking parts before starting.

5. After the boot, it works normally before it can work.

6. The end of the work, cut off the voltage.

7. Unauthorized changes to the unit may cause adverse consequences.

Packing:

Usually, we use standard export wooden cases for packing this machine. We will first wrap the entire machine with a plastic film to prevent the machine from being damaged and scratched. Then fix the fuselage with a wooden box to prevent the machine from being bumped and damaged during transportation. If you have special requirements, you can contact us.

Delivery:

For the machine, we support TNT, DHL, FedEx, UPS. If you need, we also support delivery by ship. We can also deliver the machine to your agent in China if you have.