- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

8.7*2.74*2.67

-

Year:

-

2022

-

Power (kW):

-

20 kW

-

Weight (KG):

-

38000 KG

-

Applicable Industries:

-

Waste Recycling

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine Type:

-

Tire /Plastic /Rubber Recycling Machine

-

Raw Material:

-

Tire/Plastic/Fishing net/Nylon

-

By-Products:

-

Carbon Black&steel Wire&Oil&Gail gas

-

Certificates:

-

ISO9001, CE ISO14001

-

Material Of Reactor:

-

Boiler Steel Q245R,Q345R

-

The whole time of oil yield:

-

8-10 hours

-

Heating Mode:

-

Direct Heating

-

Length:

-

5500mm--7500mm

-

Diameter:

-

2200mm--2800mm

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HUAYIN

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

8.7*2.74*2.67

-

Year:

-

2022

-

Power (kW):

-

20 kW

-

Weight (KG):

-

38000 KG

-

Applicable Industries:

-

Waste Recycling

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine Type:

-

Tire /Plastic /Rubber Recycling Machine

-

Raw Material:

-

Tire/Plastic/Fishing net/Nylon

-

By-Products:

-

Carbon Black&steel Wire&Oil&Gail gas

-

Certificates:

-

ISO9001, CE ISO14001

-

Material Of Reactor:

-

Boiler Steel Q245R,Q345R

-

The whole time of oil yield:

-

8-10 hours

-

Heating Mode:

-

Direct Heating

-

Length:

-

5500mm--7500mm

-

Diameter:

-

2200mm--2800mm

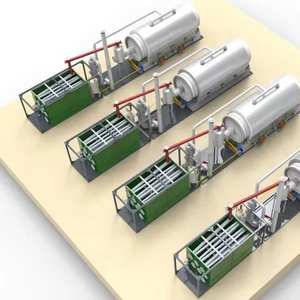

Product Application

Pyrolysis machine is designed for recycling waste tire/plastic/rubber into fuel oil to replace landfill or incineration which causes serious environmental pollution. The main output product is fuel oil that finds good market in industrial field.

Applicable raw materials : PP ,PE ABS etc.

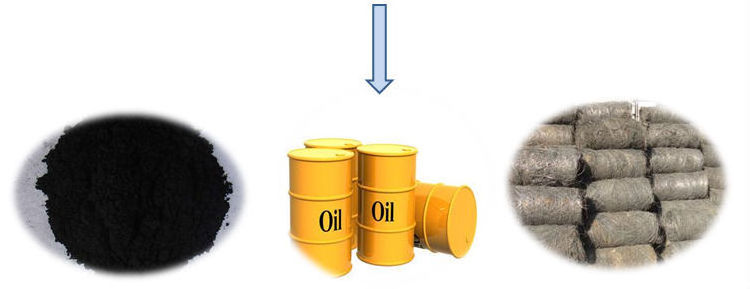

Usage of the output product

1. Fuel oil: Widely used as fuel oil in industries such as steel and iron factories, ceramics or chemical industries or hotels, restaurants etc. or used for generators to get electricity.

2. Carbon black: used for construction bricks with clay, also can be used as fuel.

3. Steel wires: Sold or reprocessing

4. Combustible gas: Can be recycled and used during process as fuel.

2. Carbon black: used for construction bricks with clay, also can be used as fuel.

3. Steel wires: Sold or reprocessing

4. Combustible gas: Can be recycled and used during process as fuel.

Product Paramenters

|

Model

|

Reactor size

|

Capacity

|

Power

|

Landing area(m)

|

|

HY-10kg

|

HY800*1880

|

10kg/batch

|

250W

|

1*4

|

|

HY-1T

|

HY1500*3000

|

1 T/batch

|

13.5KW

|

8*20

|

|

HY-5T

|

HY2200*5500

|

5 T/batch

|

29.4KW

|

10*35

|

|

HY-7T

|

HY2200*7500

|

7 T/batch

|

29.4KW

|

10*35

|

|

HY-8T

|

HY2600*6600

|

8 T/batch

|

29.4KW

|

12*35

|

|

HY-9T

|

HY2800*6000

|

9 T/batch

|

29.4KW

|

12*35

|

|

HY-10T

|

HY2800*6600

|

10 T/batch

|

32KW

|

15*35

|

|

HY-15T

|

HY2800*8000

|

15 T/batch

|

34KW

|

15*35

|

Our Advantages

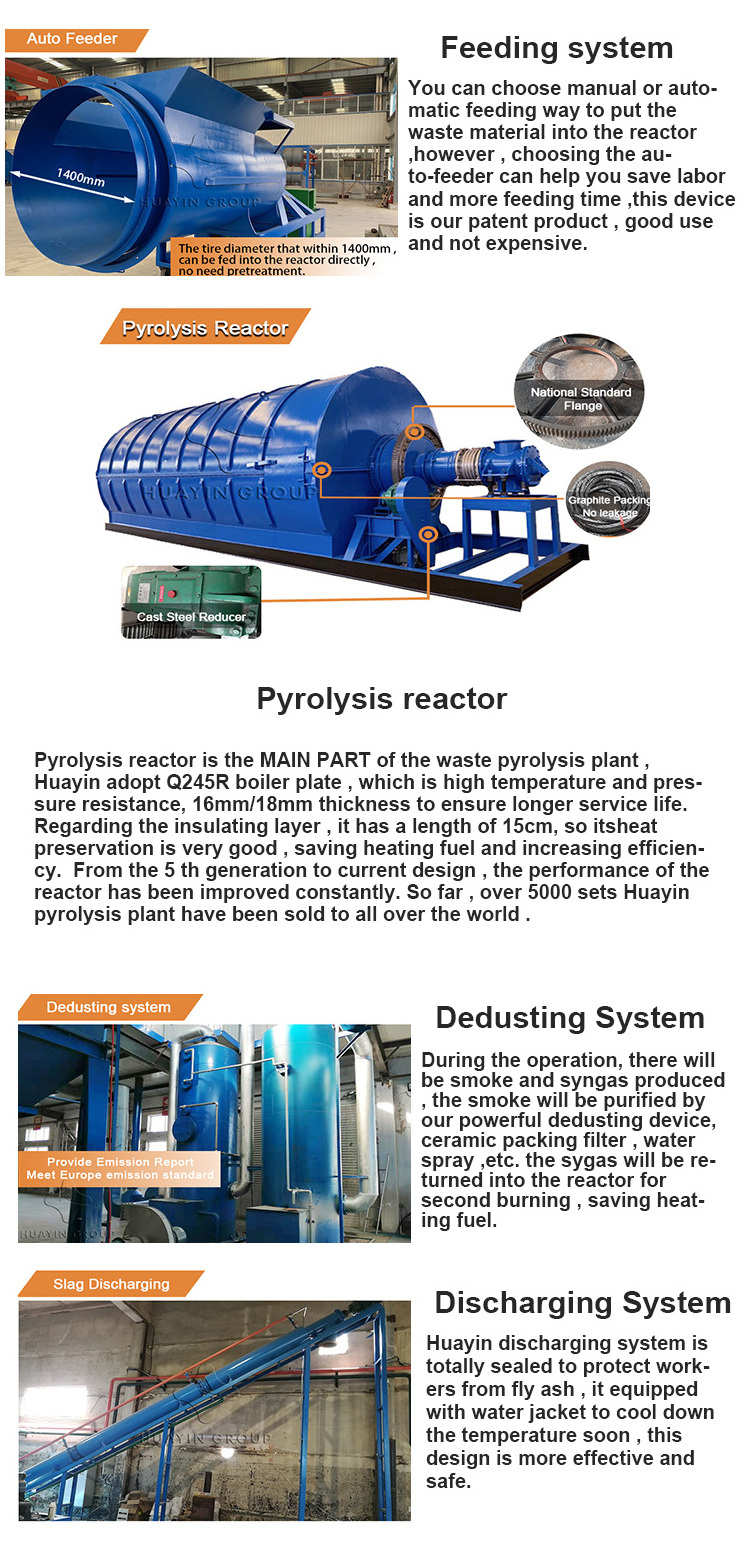

Safety:Alarm , auto pressure releasing device , and anti back fire device , vacuum pump to ensure the machine working smoothly.

Oil water separator: Its water sealing design ensures that oil and gas are separated and combustible gas can not return into the reactor.

Energy saving:

The inner reactor body and outside insulation cover have good airtightness,avoding heating loss and saving fuel.

The combustible gas below C4(oil and gas that cannot be further cooled down into fuel oil under normal temperature and pressure)will be recycled to furnace for heating the reactor,maximizing resource utilization.

The cooling water adopts circulating mode,which is pollution-free,no discharging,and recyclable.

High efficiency discharging :Adopt screw converyor discharging device , discharge carbon black in sealed condition , no pollution and save labour and time .

Integrated condensing device:All of the condensing parts have been installed together before delivery from factory , save installation time and ensure welding quality .Auto feeder machine to feed raw material automatically , save labour and time.

Motor:All of the motors can be customized.

Oil water separator: Its water sealing design ensures that oil and gas are separated and combustible gas can not return into the reactor.

Energy saving:

The inner reactor body and outside insulation cover have good airtightness,avoding heating loss and saving fuel.

The combustible gas below C4(oil and gas that cannot be further cooled down into fuel oil under normal temperature and pressure)will be recycled to furnace for heating the reactor,maximizing resource utilization.

The cooling water adopts circulating mode,which is pollution-free,no discharging,and recyclable.

High efficiency discharging :Adopt screw converyor discharging device , discharge carbon black in sealed condition , no pollution and save labour and time .

Integrated condensing device:All of the condensing parts have been installed together before delivery from factory , save installation time and ensure welding quality .Auto feeder machine to feed raw material automatically , save labour and time.

Motor:All of the motors can be customized.

Our services

1. One-stop solution.We have more than 20 years of rich experience and a good reputation. We attach great importance to customer experience and satisfaction.As long as you need, we are able to provide you with a whole high-quality production line.

2.We have our own factory and trading company, no middlemen, all products provide you with ex-factory prices, it is more convenient for you to replace related parts (as long as there is a problem, we can provide a solution immediately, product quality is guaranteed.

3.We promise that our products are efficient and have a long service life to ensure that you can quickly produce in batches.

4. Very short delivery time.

5. We can send engineer on-site to guide installation and train your workers , Lifelong maintenance of the product, providing professional use guidance services.

2.We have our own factory and trading company, no middlemen, all products provide you with ex-factory prices, it is more convenient for you to replace related parts (as long as there is a problem, we can provide a solution immediately, product quality is guaranteed.

3.We promise that our products are efficient and have a long service life to ensure that you can quickly produce in batches.

4. Very short delivery time.

5. We can send engineer on-site to guide installation and train your workers , Lifelong maintenance of the product, providing professional use guidance services.

Hot Searches