- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

U Tech

-

Year:

-

2020

-

Voltage:

-

540V/50Hz

-

Dimension(L*W*H):

-

7.8x3.6x5.4m

-

Hollow part volume:

-

200~250L

-

Screw L/D Ratio:

-

30

-

Screw diameter (mm):

-

120 mm

-

Screw Heating Power(kW):

-

40 kW

-

Extruder Motor Power(kW):

-

90 kW

-

Mold Platen Size(Width)(mm):

-

1420 mm

-

Mold Platen Size(Height)(mm):

-

1600 mm

-

Air Pressure(MPa):

-

1.4 MPa

-

Air Comsumption(m³/min):

-

2.8 m³/min

-

Die Head Heating Power(kW):

-

32 kW

-

Accumulator Capacity(L):

-

25 L

-

Power (kW):

-

112

-

Weight (T):

-

38

-

Model Number:

-

BST-120

-

Blow Moulding Type:

-

200 litre double ring drum making machine

-

Material application:

-

PP PE PVC ABS EVA

-

After sales:

-

2 years

-

PLC:

-

JAPAN MITSUBISH

-

Cavity:

-

Single

-

Color:

-

Customer Choice

-

Max Size of Mold:

-

1300x1800mm

-

Parison Control:

-

MOOG 100 Point

-

Mold material:

-

Aluminium 6061/7075,P20,etc

Quick Details

-

Clamping Force (kN):

-

1200

-

Output (kg/h):

-

350 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

U Tech

-

Year:

-

2020

-

Voltage:

-

540V/50Hz

-

Dimension(L*W*H):

-

7.8x3.6x5.4m

-

Hollow part volume:

-

200~250L

-

Screw L/D Ratio:

-

30

-

Screw diameter (mm):

-

120 mm

-

Screw Heating Power(kW):

-

40 kW

-

Extruder Motor Power(kW):

-

90 kW

-

Mold Platen Size(Width)(mm):

-

1420 mm

-

Mold Platen Size(Height)(mm):

-

1600 mm

-

Air Pressure(MPa):

-

1.4 MPa

-

Air Comsumption(m³/min):

-

2.8 m³/min

-

Die Head Heating Power(kW):

-

32 kW

-

Accumulator Capacity(L):

-

25 L

-

Power (kW):

-

112

-

Weight (T):

-

38

-

Model Number:

-

BST-120

-

Blow Moulding Type:

-

200 litre double ring drum making machine

-

Material application:

-

PP PE PVC ABS EVA

-

After sales:

-

2 years

-

PLC:

-

JAPAN MITSUBISH

-

Cavity:

-

Single

-

Color:

-

Customer Choice

-

Max Size of Mold:

-

1300x1800mm

-

Parison Control:

-

MOOG 100 Point

-

Mold material:

-

Aluminium 6061/7075,P20,etc

Product Description

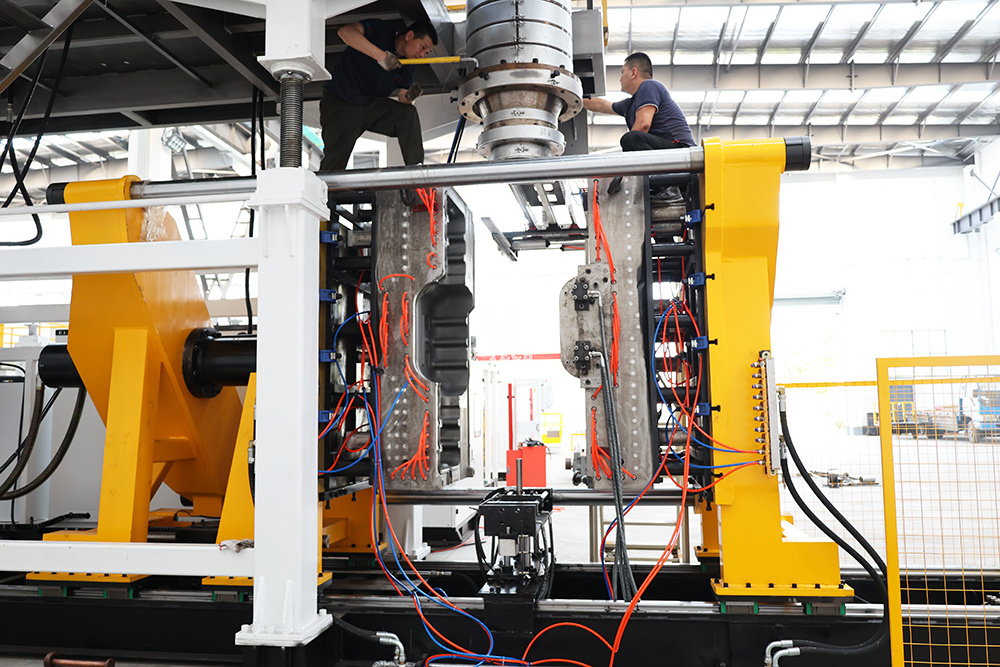

U Tech BST-120 Extrusion blow molding machine is used to produce the 200L, 250L double L-ring drum with multi-layers, such like chemical drum, plastic pallet and oil fuel tank, the machine with servo drive and high efficient HDPE extrusion output, quick and safe operation, easy for trouble shooting, maintenance and other benefit. By changing molds, can realize the production of all kind of plastic tank and drum.

Detailed Images

BST-120 250L Double-L Ring Extrusion blow molding machine

The BST-120 full automatic extrusion blow molding machine is specialized for the 250L Double-L drum volume range from 200L~250L. The machine with high efficient plasticizing screw and heating zones. The machine equips with LCD touch screen and Mitsubishi PLC system, very easy and high level operation. The blowing pin is designed to be at bottom with multi function.

LCD Touch Screen & MOOG Parison Control

MOOG 100 Points Parison Control is used to adjust the thickness of the product easily and accurately. Large LCD touch screen ensure the easy and digital operation.

Multi-function Bottom Blowing Pin & Clamp

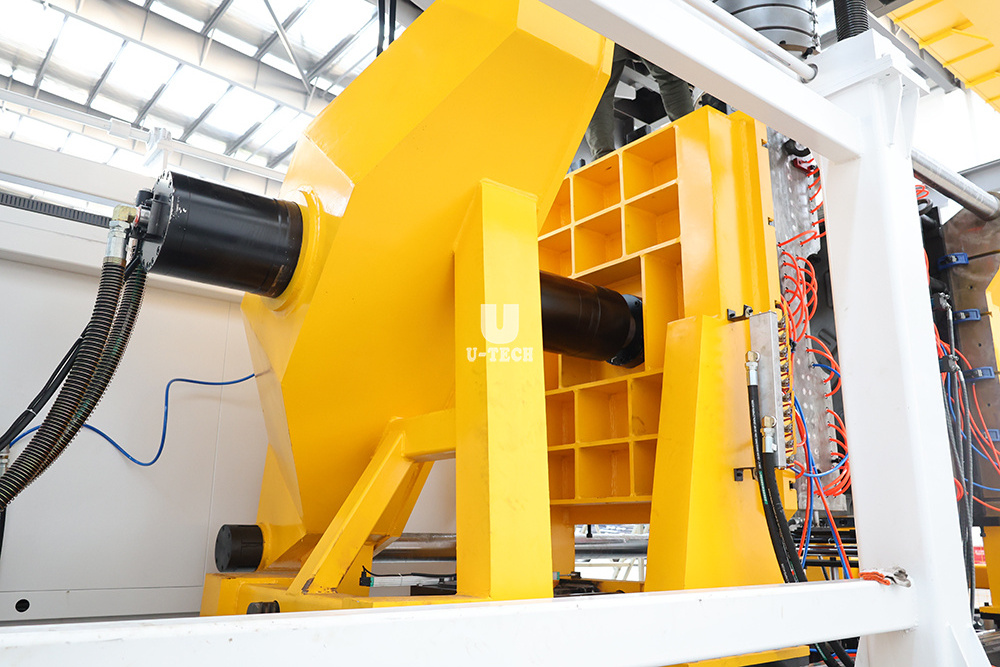

Servo Motor

Adopt International well-known brand servo motor, with accurate and energy-saving running, which can save approximate 30% energy compared to normal hydraulic system.

Electric Cabinet

Mitsubishi PLC, Omron relay, Schneider Air switch, Mean well Power resource

Product Features

1. Reasonable machine structure design and solid frame manufacturing to insure running stability.

2. Advanced die-head material runner deisgn and precision metal processing for plastic extrusion accurancy.

3. According to your specified request, our machine can be made with co-extrusion of 2~4 layers for the 250L drum and water tank.

4. Big LCD digital touch screen, cantilever operation box, bottle collective shelves, scraps sliding channel and safety protection.

5. Total machine control system well match with scraps on-line deflashing, angle adjustable blowing unit, neck rotary cutting, in-mould labeling, weight testing and leakage testing, product conveying & packing.

6. The die-head, electric parts, parision thickness controller, and motor , etc all adopt international well-known brands, to ensure the machine quality and easy to get in clients local areas.

2. Advanced die-head material runner deisgn and precision metal processing for plastic extrusion accurancy.

3. According to your specified request, our machine can be made with co-extrusion of 2~4 layers for the 250L drum and water tank.

4. Big LCD digital touch screen, cantilever operation box, bottle collective shelves, scraps sliding channel and safety protection.

5. Total machine control system well match with scraps on-line deflashing, angle adjustable blowing unit, neck rotary cutting, in-mould labeling, weight testing and leakage testing, product conveying & packing.

6. The die-head, electric parts, parision thickness controller, and motor , etc all adopt international well-known brands, to ensure the machine quality and easy to get in clients local areas.

Technical Parameter

|

Model

|

Unit

|

BST-120

|

|

Max. Product Volume

|

(L)

|

250L

|

|

Dry cycle

|

(pc/h)

|

400

|

|

Screw Diameter

|

(mm)

|

120

|

|

Screw L/D ratio

|

(L/D)

|

30

|

|

Screw drive power

|

(KW)

|

90

|

|

Screw heating capacity

|

(KW)

|

40

|

|

No. of heating zone

|

(ZONE)

|

6~8

|

|

Max. Output of HDPE

|

(Kg/hr)

|

350

|

|

Oil pump drive power

|

(KW)

|

30

|

|

Clamping force

|

(KN)

|

1000~1200

|

|

Platen distance

|

(mm)

|

650

|

|

Mold moving stroke

|

(mm)

|

800-1800

|

|

Max. Size of Mold(W*H)

|

(mm)

|

1300x1800

|

|

Max. Die diameter

|

(mm)

|

400

|

|

Die heat capacity

|

(KW)

|

32

|

|

No. of Die heating zone

|

(ZONE)

|

4~6

|

|

Central distance of Double head

|

(mm)

|

/

|

|

MOOG Parison controller power

|

(KW)

|

4

|

|

Average Power Consumption

|

(KW)

|

272

|

|

Blowing pressure

|

(Mpa)

|

1.0—1.4

|

|

Air volume

|

(M3/MIN)

|

2.8

|

|

Cooling water pressure

|

(Mpa)

|

1

|

|

Water consumption

|

(L/MIN)

|

100

|

|

Size of machine ( L*W*H)

|

(m)

|

7.80*3.60*5.40

|

|

Weight of machine

|

(TON)

|

38

|

Machine components

|

A. Hydraulic Parts

|

|

|

|

Name

|

Brand

|

|

|

valve

|

YUKEN /JAPAN

|

|

|

Proportional pressure flow valve

|

YUKEN/ JAPAN

|

|

|

Oil tuding 、attachment

|

Pike PARKER SIR/USA

|

|

|

Sealing element

|

HANSEN / JAPAN

|

|

|

B. Electric appliance

|

|

|

|

Name

|

Brand

|

|

|

Microcomputer control system

|

MITSUBSHI PLC / JAPAN

|

|

|

Touch screen

|

HIM/HITECH/TAIWAN

|

|

|

Temperature control components

|

OMRON /JAPAN

|

|

|

relay

|

SCHNEIDER/FRANCE

|

|

|

Heating method

|

SCHNEIDER/FRANCE

|

|

|

Air switch

|

SCHNEIDER/FRANCE

|

|

|

motor

|

SIEMENS/GERMANY

|

|

|

power

|

MINGWEI

|

|

|

transducer

|

DELTA/TAIWAN

|

|

|

C. Pneumatic System

|

|

|

|

Name

|

Brand

|

|

|

Control valve

|

AIRTAC/TAIWAN

|

|

|

cylinder

|

AIRTAC/TAIWAN

|

|

U Tech Advantages

|

1. Suitable for chemical raw material container, pesticide barrels, car fuel tanks, water tanks and other large amount of plastic hollow products.

|

|

|

|

|

||||

|

2. Using the Japan Mitsubishi High speed PLC and Hitech T700 colorful touch screen

|

|

|

|

|

||||

|

3. With platform lifting function which can adapt to different mold height and blow molding process requirements.

|

|

|

|

|

||||

|

4. The hydraulic system adopts proportional technology to optimize the design of hydraulic circuit and has the characteristics of electricity saving, quick movement and easy to adjust the parameters.

|

|

|

|

|

||||

|

5. Oil path flow velocity and pressure controlled by double-proportion valve; flow direction controlled by reversing valve; deceleration valve brake functions smoothly and quickly. The automatic lubrication system to reduce equipment maintenance workload.

|

|

|

|

|

||||

|

6. It adopts famous factory’s pneumatic, hydraulic and electrical control components which has long service life.

|

|

|

|

|

||||

|

7. Diehead plastic pressurizing piston and material accumulation chamber use extremely hard wear-resistant material and hence long service life and durable.

|

|

|

|

|

||||

|

8. The machine is equipped with down widen device, which can stretch the material tube to both sides, and then blow up to make the bottle shape more symmetrical and full.

|

|

|

|

|

||||

|

9. For large diameter pipe, the machine is equipped with pre-clamped embryo device adhesive nozzle to pen blowing.

|

|

|

|

|

||||

|

10. Pre-sealed cutter device can ensure that the length of the extruded tube is consistent so as to avoid the waste of raw materials and can not be blow molding caused by the too long tube.

|

|

|

|

|

||||

|

11. Strengthen and hard cold processing screw, equipped with plastic die head, double plasticizing, good plasticizing effect, large amount of extrusion screw, barrel wear resistance.

|

|

|

|

|

||||

|

12. The force design of the mould plate center ensures the balance of clamping force.

|

|

|

|

|

||||

|

13. The whole mold template system are used ductile iron, which is stable and solid, durable and not deformed.

|

|

|

|

|

||||

|

14. Pressure gauge, die blowing throttle valve, pen blowing throttle valve arranged in a centralized placement and equipped with platform fence.

|

|

|

|

|

||||

Mold Details

Company Introduction

Zhangjiagang U Tech Machine Co., Ltd. is a manufacturer of filling machine and packing with well-equipped testing facilities and strong technical force. With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in beverage and other packing equipment.Our products include: liquid filling machines (water, fruit juice/tea, carbonated drink, oil, alcohol, plant protein drink, etc.), barreled filling line (3-5 gallon) water treatment machines, labeling & packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC...) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.We can provide best services for customers, from plant layout, equipment manufacture and production line setup to operator training and best after-sales service. All machines are two years' service for all parts, 24 hours for engineer response (all services part 5days in customer hand by Intl' courier). Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success !

FAQ

What service U Tech Machine Co.,Ltd can offer you ?

• Well-trained & experienced staff are to answer all your inquiries in English and Chinese

• 24 hours for engineer response (all services part 5days in customer hand by Intl' courier).

• 2 Years guarantee

• Your business relationship with us will be confidential to any third party.

• Good after-sle service offered, please get back to us if you got any questions

FAQ

Factory Automatic 1-5Liter plastic Jerry can extrusion blow molding machine for good price

Q1:Are you a trading company or a manufactory?

A1:We are a manufactory,can give u best service .

Q2:What’s your guarantee or the warranty of the quality if we buy your machines?

A2:We offer you high quality machines with 2 years guarantee . we will give u spare part free in 2 years

Q3:When can I get my machine after I paid?

A3:We will deliver the machines on time as the date we agreed both side.

Q4:How can I install my machine when it arrives?

A4:We will send our engineer to your side as soon as you get all your machines ready , for testing and teaching your technicians how to run the machines.

Q5:How about the spare parts?

A5:After we deal down all the things , we will offer you a spare parts list for your reference.

• 24 hours for engineer response (all services part 5days in customer hand by Intl' courier).

• 2 Years guarantee

• Your business relationship with us will be confidential to any third party.

• Good after-sle service offered, please get back to us if you got any questions

FAQ

Factory Automatic 1-5Liter plastic Jerry can extrusion blow molding machine for good price

Q1:Are you a trading company or a manufactory?

A1:We are a manufactory,can give u best service .

Q2:What’s your guarantee or the warranty of the quality if we buy your machines?

A2:We offer you high quality machines with 2 years guarantee . we will give u spare part free in 2 years

Q3:When can I get my machine after I paid?

A3:We will deliver the machines on time as the date we agreed both side.

Q4:How can I install my machine when it arrives?

A4:We will send our engineer to your side as soon as you get all your machines ready , for testing and teaching your technicians how to run the machines.

Q5:How about the spare parts?

A5:After we deal down all the things , we will offer you a spare parts list for your reference.

Hot Searches