- Product Details

- {{item.text}}

Quick Details

-

Core Components:

-

Other

-

Product Name:

-

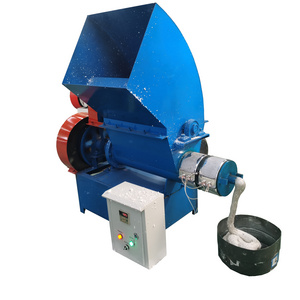

EPS Foam Polyethylene foam shredding melting recycling machine

-

Processing type:

-

cold press compactor

-

compress volume:

-

6-20 m3/h

-

Production Capacity (kg/h):

-

100 - 2000 kg/h

-

Name:

-

Waste Palstic Compactor

-

Type:

-

Single screw

-

Usage:

-

EPS foam block compacting machine

Quick Details

-

Place of Origin:

-

China

-

Machine Type:

-

EPS Shape Moulding Machine

-

Weight (KG):

-

500 KG

-

Core Components:

-

Other

-

Product Name:

-

EPS Foam Polyethylene foam shredding melting recycling machine

-

Processing type:

-

cold press compactor

-

compress volume:

-

6-20 m3/h

-

Production Capacity (kg/h):

-

100 - 2000 kg/h

-

Name:

-

Waste Palstic Compactor

-

Type:

-

Single screw

-

Usage:

-

EPS foam block compacting machine

Introduction of

Foam compactor adopts the principle of pressure

produced by the rotation of screw extrusion foam, to cold compression processing machinery and environmental protection

equipment.When used, the operator as long as the bubble into the hopper, torn and broken through equipment institution for bubble

break spiral compression, after dealing with the screw mechanism to produce square block foam compression.Have multiplied reducing

bubble size, density, foam recycling.

produced by the rotation of screw extrusion foam, to cold compression processing machinery and environmental protection

equipment.When used, the operator as long as the bubble into the hopper, torn and broken through equipment institution for bubble

break spiral compression, after dealing with the screw mechanism to produce square block foam compression.Have multiplied reducing

bubble size, density, foam recycling.

Advantages of our foam block compactor:

1.Non-toxic, no smell.Green environmental

protection.

2.Cold pressing type EPS block making machine, in the absence of heating directly on the EPS foam, refrigerator inner pushing

extrusion, PU foaming cotton.

3.Compression ratio is big, the biggest can reduce capacity 50 times.Foam cotton minus volume 8 times.

4.To save storage space, save transportation and warehousing costs.

5.Large machine with conveyor belt can be synchronous operation, improve production efficiency.

protection.

2.Cold pressing type EPS block making machine, in the absence of heating directly on the EPS foam, refrigerator inner pushing

extrusion, PU foaming cotton.

3.Compression ratio is big, the biggest can reduce capacity 50 times.Foam cotton minus volume 8 times.

4.To save storage space, save transportation and warehousing costs.

5.Large machine with conveyor belt can be synchronous operation, improve production efficiency.

Used for

Final production

Machine details show

Main parameter of

Picture shows of

Hot sale and good feedback

How to contact us

FAQ

|

MOQ

|

Normal product is 1set, the price is negotiable for large quantity

|

|

Voltage

|

110V 220V 380V 400V 50HZ/60HZ Single /three phase custom-made voltage

|

|

Guarantee

|

Quality guarantee term is for one year.

|

|

Payment

|

T/T , L/C Credit card .Alipay wechat, Western Union . cash E-checking , MoneyGram.RMB

|

|

The Date of delivery

|

Generally within 7working days. If there is a need for special customization, it may take a little longer.

|

|

After-sales service

|

Before sales

24 hours online service .in time reply Any inquiries will be replied within 12 hours provide professional machine details and technology information. After sales Fast delivery and test and adjust machine working well before delivery sending manual book and technical support in order to use well providing install pictures or videos and dispatch the engineer if necessary |

|

Address

|

Our factory is located in Zhengzhou, Henan Province, China. Welcome to our company

|

Hot Searches