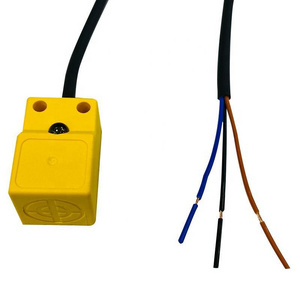

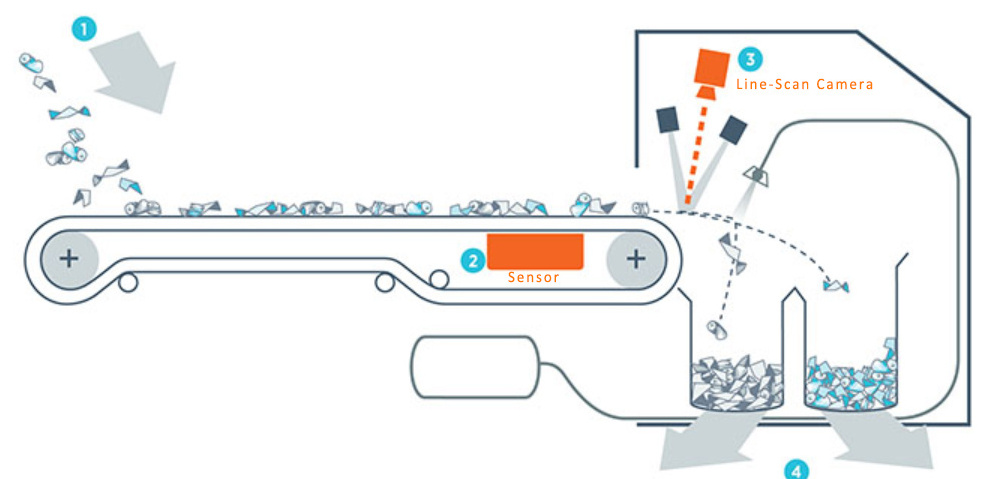

Induction sorting system includes an acceleration belt on which the sortable material is transported through the detection area while at rest. Under the conveyor belt, there is a modern inductive metal sensor that produces an electromagnetic field. Any conductive object passing through the sensor area is detected at a sensitivity of significantly less than 1 mm. Following detection , the metal part to be sorted is deflected from its trajectory using a targeted blast of compressed air and is ejected from the material stream.

For more complex tasks require more elaborate signal capture and interpretation combination sorting system controller. The purely digital sensor combines conductivity detection and image processing, thereby improving the sorting result because the sensor provides more accurate information about all particles detected. The sophisticated

view of the inductive metal signals enables enhanced sorting, for example, sorting between stainless steels, cables and circuit boards.combination sorting system controller.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

ISS 600-2400

-

Power:

-

5

-

Material:

-

in bulk

-

Warranty of core components:

-

8year

-

Core Components:

-

high frequency high intensity magnetic rotor, electromagnetic sensor technology, electromagnetic conductivity detector, combination sorting system controller, camera image processing system

-

Weight (KG):

-

4000 kg

-

Application:

-

Metal separation in different recycling industry

-

suitable material:

-

shredder residue recycling

-

installation ways:

-

after magnetic sorting and Eddy Current Separation

-

working principle:

-

electromagnetic sensor

-

Final product:

-

zurik scraps stainless steel fraction

-

Size:

-

600-2400mm belt width model available

-

working style:

-

all metal separator stainless steel style

-

Keywords:

-

metal sorter

-

Certification:

-

CE

-

Technology:

-

inductive metal sorter

Quick Details

-

Production Capacity:

-

1-10t/h

-

Applicable Industries:

-

Induction sensor for any metals, Waste Treatment Machinery, Scrap & salvage vehicle processors, Car Recycling Machinery, Vehicle waste recycling systems, Recycling Systems & Equipment, car recycling, Auto Recycling, Electronic Devices recycling, Small and large appliances recycling, aluminum profiles recycling, Construction Material recycling, household Items recycling, Industrial Scrap recycling, Auto salvage recycling, Wreckage Auto-Salvage recycling, JUNK CARS recycling, shredder residue recycling, recycled consumer processing

-

Place of Origin:

-

Liaoning, China

-

Model Number:

-

ISS 600-2400

-

Power:

-

5

-

Material:

-

in bulk

-

Warranty of core components:

-

8year

-

Core Components:

-

high frequency high intensity magnetic rotor, electromagnetic sensor technology, electromagnetic conductivity detector, combination sorting system controller, camera image processing system

-

Weight (KG):

-

4000 kg

-

Application:

-

Metal separation in different recycling industry

-

suitable material:

-

shredder residue recycling

-

installation ways:

-

after magnetic sorting and Eddy Current Separation

-

working principle:

-

electromagnetic sensor

-

Final product:

-

zurik scraps stainless steel fraction

-

Size:

-

600-2400mm belt width model available

-

working style:

-

all metal separator stainless steel style

-

Keywords:

-

metal sorter

-

Certification:

-

CE

-

Technology:

-

inductive metal sorter

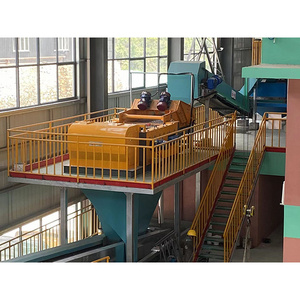

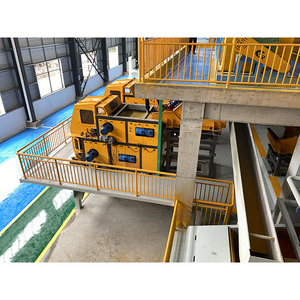

Working principle of electromagnetic sensor sorter :

two different types of sensors also could be avialiable depending on the requirement .

1.all-metal separator for simple applications, such as producing a residue containing no metal

2.conductivity detection and image processing combination sorting system also could avialiable to improve the sorting result.sensor provides more accurate information about all particles detected. The sophisticated view of the inductive metal signals enables enhanced sorting, for example, sorting between stainless steels, cables and circuit boards. available in working widths from 600 mm to 2400 mm.

process technology

After appropriate screening, classifying , Cyclone Separation steps , Induction Sorting System installed after #magnetic Separator and Eddy Current Sorter perfect for recovering Residual Metals Inductive Metal from a mix of materials.

Trommel for screening

Cyclone Separator for dust and fluff

Overband magnet for big flow ferrous

Drum Magnet for bottom ferrous

Both Eccentric & Concentric available

Inductive sensor sorting unit

Hot Searches