>>High specific output for gentle plastification of PVC material

>>

High melt homogenity even with high-filled material formulations

>>

Optimized material feeding system for stable production of PVC-U powder

>>

Bimetallic material screw and barrel ensuring long time working without trouble

>>

Suitable for PVC-U high-filled pipe production

>>

Output range from 150kg/h-900kg/h

>>

Touch screen control panel

>>

User friendly software developed by KITECH

>>

AC motor drive by inverter

>>

Vertical integrated structured gear box

>>

Equipped with degassing zone

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

30 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Kitech

-

Voltage:

-

380V , 50Hz or Customized

-

Dimension(L*W*H):

-

25000x5000x6000mm

-

Power (kW):

-

120

-

Weight:

-

36000 KG

-

Name:

-

Plastic PVC Pipe Making Machine PVC Pipe Extruder Machine

-

Keywords:

-

pvc pipe making machine

-

Raw material:

-

PVC Powder

-

Product Type:

-

PVC Pipes

-

Automatic Grade:

-

High Automation

-

Color:

-

Customers' Require

-

Motor:

-

Siemens Beide

-

Inverter:

-

ABB Brand

-

Screw type:

-

Twin Conical Screw

-

Temperature control:

-

Omron Brand

-

Marketing Type:

-

New Product 2022

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

Other

-

Screw diameter (mm):

-

Other

-

Screw Speed (rpm):

-

30 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Kitech

-

Voltage:

-

380V , 50Hz or Customized

-

Dimension(L*W*H):

-

25000x5000x6000mm

-

Power (kW):

-

120

-

Weight:

-

36000 KG

-

Name:

-

Plastic PVC Pipe Making Machine PVC Pipe Extruder Machine

-

Keywords:

-

pvc pipe making machine

-

Raw material:

-

PVC Powder

-

Product Type:

-

PVC Pipes

-

Automatic Grade:

-

High Automation

-

Color:

-

Customers' Require

-

Motor:

-

Siemens Beide

-

Inverter:

-

ABB Brand

-

Screw type:

-

Twin Conical Screw

-

Temperature control:

-

Omron Brand

-

Marketing Type:

-

New Product 2022

Products Description

>>

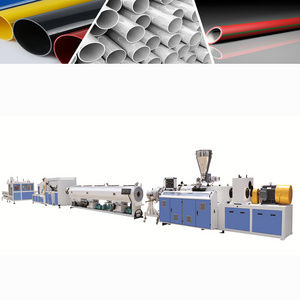

PVC Plastic pipe making machine

is mainly used in the production of Agricultural water supply & water discharge system, architectural water supply & discharge system, wire laying system, etc. purposes.

>>

The unit consists of Conical (Parallel) double screw extruder-PVC pipe mold-Vacuum forming tank-Haul-off machine-Cutting machine-Stacker/Belling machine.

>>

And the line can be equipped with Comptroller thickening instrument or computer ink-jet printer, etc. to achieve the production and manufacture of high-grade tubing.

>>

Process Flow:

Screw Loader for Mixer→ Mixer unit→ Screw Loader for Extruder→ Conical Twin Screw Extruder → Mould → Vacuum Calibration Tank → Four claws Haul-off → Planetary Saw Cutter → Belling machine/ Tripping Table → Final Product Inspecting &Packing

Details Images

Conical twin screw extruder

PVC pipe die head

>>Suitable for PVC-U and CPVC pipe production

>>Diameter range from Ø16 to Ø1000 mm

>>High melt homogenity

>>Low pressure built up even with high outputs

>>Melt channel distribution system

>>Equipped with seramic heaters

>>Pipe head carriage for easy movement

>>Pipe heads are designed according to application requirements.

>>Easy maintenance thanks to the optimized and proven designed construction

>>Diameter range from Ø16 to Ø1000 mm

>>High melt homogenity

>>Low pressure built up even with high outputs

>>Melt channel distribution system

>>Equipped with seramic heaters

>>Pipe head carriage for easy movement

>>Pipe heads are designed according to application requirements.

>>Easy maintenance thanks to the optimized and proven designed construction

Vacuum cooling tank

>>

Suitable for PVC pipe production

>> Diameter range from Ø16 to Ø1000 mm

>> Length up to 12000mm

>> 304 stainless steel with painted outer surface

>> Special water sprays are located on the best position for cooling the pipe efficiently

>> Special and easy adjusted pipe supports for each pipe diameter

>> Installed vacuum and water pumps can work without any maintenance for long times

>> Special cooling baths can be designed for specific extrusion production

>> Diameter range from Ø16 to Ø1000 mm

>> Length up to 12000mm

>> 304 stainless steel with painted outer surface

>> Special water sprays are located on the best position for cooling the pipe efficiently

>> Special and easy adjusted pipe supports for each pipe diameter

>> Installed vacuum and water pumps can work without any maintenance for long times

>> Special cooling baths can be designed for specific extrusion production

Haul off

>>

Pipe range from Ø16 to Ø1000 mm

>> High pulling force without lose the shape of the pipes

>> Equipped with 2, 3, 4, 6, 8 or 10 caterpillars according to the application

>> Motorized positioning of the lower caterpillars

>> Simple operation

>> Completely closed protection for maximum safety

>> Chain conveyors with special rubber pads on chains which do no mark on the pipe.

>> Synchronization with the extruder screw speed allows stable production during changing the production speed

>> High pulling force without lose the shape of the pipes

>> Equipped with 2, 3, 4, 6, 8 or 10 caterpillars according to the application

>> Motorized positioning of the lower caterpillars

>> Simple operation

>> Completely closed protection for maximum safety

>> Chain conveyors with special rubber pads on chains which do no mark on the pipe.

>> Synchronization with the extruder screw speed allows stable production during changing the production speed

Planetary cutter

>>

Automatic synchronisation with extrusion speed

>> Planetary equipped with disk and milling cutter for cut and chamfering

>> Touch screen control panel

>> User friendly software developed by KITECH

>> All movements are motorised and controlled by control panel

>> Pipe blocking vices device

>> Type of the cutting unit is chose depend on pipe

>> Less maintenance needs

>> Completely closed and secured machine for maximum safety

>> Planetary equipped with disk and milling cutter for cut and chamfering

>> Touch screen control panel

>> User friendly software developed by KITECH

>> All movements are motorised and controlled by control panel

>> Pipe blocking vices device

>> Type of the cutting unit is chose depend on pipe

>> Less maintenance needs

>> Completely closed and secured machine for maximum safety

Belling machine

>>

Suitable for PVC pipe production

>> Universal automatic belling machines for 4 different socketing types

>> Diameter range from Ø20 mm to Ø1000 mm

>> Socket forming: smooth (solvent cemented)

>> Socket forming: shaped for insertion of rubber gasket (blowing system)

>> Socket forming: collapsible system

>> Socket forming: auto-load rubber gasket

>> Touch screen control panel

>> User friendly software developed

>> Automatic synchronisation with extrusion speed

>> Pneumatic, hydraulic and motorized movements

>> High quality belling tools

>> Universal automatic belling machines for 4 different socketing types

>> Diameter range from Ø20 mm to Ø1000 mm

>> Socket forming: smooth (solvent cemented)

>> Socket forming: shaped for insertion of rubber gasket (blowing system)

>> Socket forming: collapsible system

>> Socket forming: auto-load rubber gasket

>> Touch screen control panel

>> User friendly software developed

>> Automatic synchronisation with extrusion speed

>> Pneumatic, hydraulic and motorized movements

>> High quality belling tools

Product Paramenters

|

Diameter ranges(mm)

|

Extruder model

|

Max. Capacity(kg/h)

|

Max. lineal speed(m/min)

|

Extruder motor power(kw)

|

|

16-32 (4-cavities)

|

ACE65/132

|

300

|

10*4

|

37

|

|

20-63 (Dual)

|

ACE65/132

|

300

|

15*2

|

37

|

|

50-160

|

ACE65/132

|

300

|

8

|

37

|

|

75-250

|

ACE80/156

|

500

|

6

|

55

|

|

110-315

|

ACE80/156

|

500

|

4

|

55

|

|

75-160 (Dual)

|

ACE92/188

|

850

|

6

|

110

|

|

315-630

|

ACE92/188

|

850

|

1.2

|

110

|

|

Technical Parameter of Main extruder

|

|

|

|

|

|

|||||

|

Model

|

Power

(kw)

|

Screw Diameter (mm)

|

Screw Qty.

|

Designed Output (kg/h)

|

Dimension(L*W*H)

(mm)

|

|||||

|

ACE-45/90

|

15

|

Φ45/90

|

2

|

70

|

3360x1290x2127

|

|||||

|

ACE-51/105

|

18.5

|

Φ51/105

|

2

|

100

|

3360x1290x2127

|

|||||

|

ACE-55/110

|

22

|

Φ55/110

|

2

|

150

|

3620x1050x2157

|

|||||

|

ACE-65/132

|

37

|

Φ65/132

|

2

|

300

|

3715x1520x2450

|

|||||

|

ACE-80/156

|

55

|

Φ80/156

|

2

|

400

|

4750x1550x2460

|

|||||

|

ACE-92/188

|

110

|

Φ92/188

|

2

|

750

|

6725x1550x2814

|

|||||

Why Choose Us

Customer Photos

Hot Searches