- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

1L, 1L

-

Use:

-

Engine lubrication system cleaning

-

Expiration Date:

-

3 Years

-

Product name:

-

Engine Lubrication System Stubborn Dirt Cleaning Fluid

-

MOQ:

-

1000 pcs

-

OEM:

-

Accpet

-

Service:

-

7/24 Hours

-

Advantage:

-

Highly Effective

-

Color:

-

Customized Color

-

LOGO:

-

Accept Customized Logo

-

Packing:

-

Plastic Bottle

-

Payment:

-

T/T

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

LYYD

-

Model Number:

-

B3063

-

Weight:

-

1L, 1L

-

Use:

-

Engine lubrication system cleaning

-

Expiration Date:

-

3 Years

-

Product name:

-

Engine Lubrication System Stubborn Dirt Cleaning Fluid

-

MOQ:

-

1000 pcs

-

OEM:

-

Accpet

-

Service:

-

7/24 Hours

-

Advantage:

-

Highly Effective

-

Color:

-

Customized Color

-

LOGO:

-

Accept Customized Logo

-

Packing:

-

Plastic Bottle

-

Payment:

-

T/T

This product is a new type of cleaning agent developed for the engine due to piston ring deposits stagnation, resulting in "excessive oil loss" (commonly known as oil burning), and other failures caused by excessive deposits. It is a unique product in the industry, eliminating the use of rinsing fluid, significantly shortening the cleaning time, and avoiding the safety hazards of unclean waste fluid discharge.

The product is suitable for both diesel and gasoline engines, no special supporting equipment is needed, just a simple injection of alternative oil, and then run at low idling speed for 3 to 5 hours to solve the piston ring burning oil problem. For inadvertent use of shoddy engine oil, or delayed oil changes resulting in excessive deposits and other failures, the same applies to this product.

The product is non-corrosive to metal, non-swelling to rubber, plastic parts and resin coating, and has anti-wear property to the shaft tile, so the correct use can fully ensure its cleaning effect and application safety.

This product is a new type of cleaning agent developed for the engine due to piston ring deposits stagnation, resulting in "excessive oil loss" (commonly known as oil burning), and other failures caused by excessive deposits. It is a unique product in the industry, eliminating the use of rinsing fluid, significantly shortening the cleaning time, and avoiding the safety hazards of unclean waste fluid discharge.

The product is suitable for both diesel and gasoline engines, no special supporting equipment is needed, just a simple injection of alternative oil, and then run at low idling speed for 3 to 5 hours to solve the piston ring burning oil problem. For inadvertent use of shoddy engine oil, or delayed oil changes resulting in excessive deposits and other failures, the same applies to this product.

The product is non-corrosive to metal, non-swelling to rubber, plastic parts and resin coating, and has anti-wear property to the shaft tile, so the correct use can fully ensure its cleaning effect and application safety.

The five types of ester synthetic oils commonly used in high-end synthetic motor oil, because itself is the acid and alcohol of The product of water loss, under the catalyst of acid or alkali, it is easy to hydrolyze into the corresponding acid and alcohol, so the insufficient oxidation stability is also one of the important reasons for the generation of deposits.

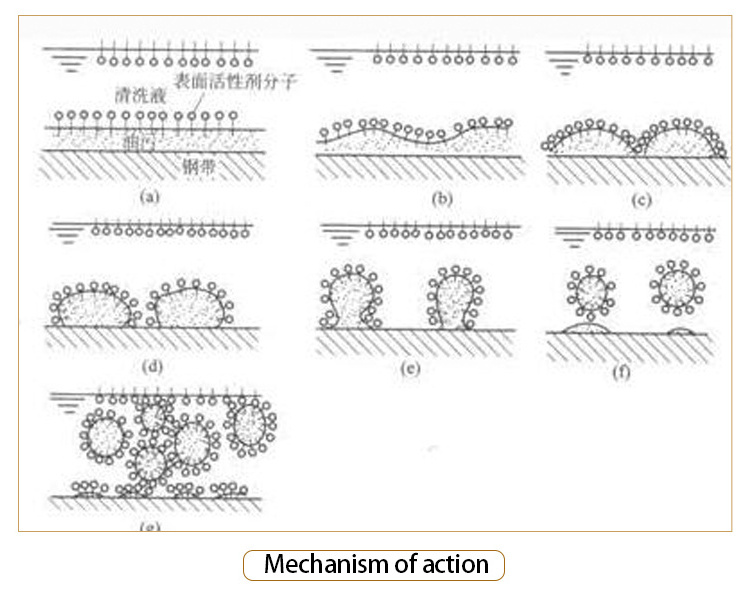

This product is a combination of specially developed nonionic surfactant with penetrant and synthetic co-solvent, and the system is extremely reactive to polar deposits. The two ends of the surfactant molecule are designed with special non-polar and polar groups that adsorb to the co-solvent and the deposit, respectively. The non-polar groups ensure that the molecules are fully soluble in the solvent, while the polar groups can be effectively adsorbed on the polar deposit surface.

Surfactants form large concentrations of micelles in the co-solvent. These micelles are normally Once they come into contact with polar substances (insoluble substances), the surfactants will break away from the micelles and rapidly disperse and adhere to their surfaces, forming an outer "oil-soluble film". The surfactants are rapidly dispersed and adhere to the surface of the micelles, forming an outer "oil-soluble film", so that the polar substances are wrapped and gradually dispersed in the system. The polar substances are wrapped and gradually dispersed in the system to achieve the dissolution and cleaning effect of the product on the sediment.

Similar to the mechanism of carbon formation and removal at the piston ring, the varnish formed at a slightly lower temperature in the lubrication system and even at a lower temperature is deposited. The varnish formed at a slightly lower temperature and even the low temperature sludge formed at a lower temperature can be quickly dissolved and dispersed by this product because it has the same It can be dissolved and dispersed by this product quickly because of its polar characteristics.

Under the engine idle speed, this product in the lubricating oil channel for continuous circulation cleaning, in high temperature (90-180℃) and mechanical agitation synergistic action, a certain period of time can be solid deposits dissolved in the cleaning fluid. Subsequently, through thorough evacuation, the engine lubrication system can be realized The engine lubrication system can be cleaned without disassembly.

(1) Super dissolution cleaning power, simulated/real car disassembly test can be seen with the naked eye

The piston ring (oil ring) collected in the overhaul shop was soaked in the quantitative liquid for 1h at 150℃ (simulating the operation temperature of the piston ring), and the deposit in the groove of the piston ring was completely dissolved, with the effect of renovation visible to the naked eye.

In the real car test organized all over the country (many times before and after the real car test dismantling comparison), the participating mechanics are generally impressed with the "new look" after cleaning, this product has excellent cleaning power to the lubrication system stubborn dirt of all models on the market.

(2) Excellent application safety

With reference to the corresponding index requirements of internal combustion engine oil standards, the product strictly controls the technical indexes of viscosity, low-temperature fluidity, resin/rubber swelling, metal corrosion, friction reduction and extreme pressure of the cleaning fluid. Through the wear and friction reduction test of the pasteurized alloy shaft tile, the product is self-lubricating and there is no need to worry about the problem of poor lubrication. In terms of metal corrosion prevention, it has passed the severe 150℃ high temperature (oil standard is usually 100℃) copper corrosion and aluminum corrosion weight loss test, and they all meet the requirements. When used under the specified conditions (100℃, 5h), there is no damage to the anti-wear coating on the piston skirt, the oil pan varnish and the rubber and plastic parts of the car.

This product can be completely dissolved in engine oil, does not contain ash, and has no significant negative impact on the original index of the engine oil, basically eliminating the blockage of the oil circuit due to the exhaustion of waste liquid discharge, and thus causing other construction accident potential problems.

(3) The operation process is simple and does not require professional supporting equipment

The cleaning time of this product is usually 3-5h, the inspection and waste liquid emptying can be completed within 30 minutes, with low labor cost. One person can complete the whole process without heavy physical and intellectual requirements. The construction process only requires pneumatic oil extractor (for oil sump residual oil), no other special cleaning equipment is required.

(4) Comprehensive "intergenerational" advantages over other governance methods

For the oil burning caused by the piston ring carbon stagnation, other feasible ways of treatment are mainly "disassembly overhaul" and "combustion chamber liquid injection cleaning".

The cost of disassembly overhaul is high (at least not less than 10,000 yuan), and the risk and cost of maintenance are not low, and there are problems of assembly precision, which is difficult to be accepted by car owners.

The cost of "combustion chamber cleaning" is slightly lower, but it still requires at least 2-3 people to work continuously for more than 10 hours, and it is difficult to avoid the threat to the lubrication system, and the efficiency is usually less than 60%, which is not satisfactory to the users.

This product has the characteristics of high efficiency, low cost and low risk, with a pioneering comprehensive advantage is clearly better than the first two, easy to be accepted by car owners, maintenance terminals and brand operators and other parties.

1. Start the engine to warm up (if you want to shorten the warm-up time, you can increase the speed moderately), connect the testing computer, read the oil temperature data, turn off the engine after the curved oil temperature reaches 90℃, then empty the old oil.

Note: High temperature when the oil viscosity is small, easy to empty thoroughly, to avoid the old oil hanging wall and residue; residual larger will dilute the cleaning fluid, and consume the effective concentration of cleaning fluid, and then affect the cleaning performance.

2. Use the "negative pressure oil extractor" to thoroughly pump out the residual oil from the oil pan and the base of the filter, and disassemble the oil filter and oil radiator to completely empty the residual fluid inside and replace it with a new oil filter.

Note: Gravity (self-flow) oil draining method will leave more old oil inside the oil pan, therefore, "negative pressure oil pumping equipment" should be used for construction; the old oil in the oil filter and oil radiator is often neglected and should be emptied with attention.

3. Add the same amount (or slightly higher, not higher than the upper limit of the dipstick) of this product according to the specified oil dosage, start the engine and keep idling for 3-5h, connect the testing computer during the operation and pay attention to the changes of engine running conditions.

Note: Simulation and real car tests show that when the amount of cleaning fluid dissolved sediment reaches a critical value, its cleaning power will rapidly decay; usually burn oil vehicles at idle speed within 5h have good cleaning ability, no need to extend the length of cleaning.attention.

4. Repeat step 2 after turning off the engine, empty the product completely, replace the new oil filter at this time, add the specified grade of new engine oil and start the vehicle.

5. Check the engine running condition and read the relevant data, compare with the data record before the construction, confirm no abnormalities and then finish the construction.

●Vapors are irritating to eyes and nose; eye contact can cause damage, skin contact causes stinging and burns; oral exposure damages the mouth and respiratory tract; goggles, goggles, rubber gloves should be worn when exposure is possible gas mask or rubber gloves when exposure is possible.

●It has the risk of causing combustion when exposed to high temperature, open fire or in contact with oxidizer; use fog water, carbon dioxide, sand, foam, dry powder, etc. when extinguishing the fire.

●It is easy to be oxidized in contact with air and high temperature, and should be stored in a cool and dry place under seal.

|

Test item

|

Technical index

|

Typical index

|

Test method

|

|||

|

Appearance

|

Clear, transparent, yellow Color liquid

|

Clear, transparent, yellow Color liquid

|

Visual inspection

|

|||

|

Density (20℃)

|

0.8901±0.015

|

0.8919

|

GB/T 1884

|

|||

|

Kinematic viscosity (40℃), mm2 /s

|

40.5±5.0

|

39.4

|

GB/T 265

|

|||

|

Kinematic viscosity (100℃), mm2 /s

|

5.9±0.5

|

5.84

|

GB/T 265

|

|||

|

Pour point, °C

|

≤-5

|

-11

|

GB/T 3535

|

|||

|

Flash point (open), ℃

|

≥110

|

113

|

GB/T 3536

|

|||

|

Refractive index (30℃)

|

1.4755±0.0015

|

1.4759

|

GB/T 6488

|

|||

|

Moisture, %

|

≤0.5

|

0.1

|

GB/T 260

|

|||

|

Mechanical impurities, %

|

≤0.1

|

None

|

GB/T 511

|

|||

|

Copper sheet corrosion (150℃, 3h), grade

|

≤1

|

1a

|

GB/T 5096

|

|||

|

Corrosion of aluminum sheet (150℃, 3h) Corrosion rate, g/(m²-h) Total corrosion, g/m²

|

≤0.5

≤1.5

|

0.1

0.3

|

GB/T 25147

|

|||

|

Swelling property of lubricating polymer (100℃, 120min) Polyamide plastic Epoxy resin coating Silicone rubber (standard seal)

|

None

None

None

|

None

None

None

|

Q/DXLZ 040S

|

|||

|

Lubrication system coking deposit dissolution decline Rate, %

|

≥90

|

96.2

|

Q/DXLZ 041S

|

|||

|

a. The specimen is injected into a 100mL glass measuring cylinder and observed at room temperature (20℃±5℃) and should be transparent, without turbidity, no stratification, no suspended and settled water and impurities.

|

|

|

|

|||

LYYD, registered in Daxing District, Beijing, China, is a well-known supplier of automotive maintenance (new) chemicals in the industry, serving more than 130 brand operators such as 3M in the United States in a business-to-business manner.

Products include: all kinds of fuel/lubricating oil additives, engine carbon cleaning agent, automotive aftertreatment system cleaning agent, automotive air conditioning cleaning fluid, automotive appearance cleaning agent, automotive beauty chemicals, etc.

The technology comes from LZLY (Beijing) Energy Conservation and Environmental Protection Technology Research Institute, a famous scientific research institution in the industry, which is the only market transformation party of its technological achievements.

Through technology transfer, LYYD will organize production and sales, and be responsible for user technical services.LYYD has two product blending production bases and one organic synthesis production base, located in Tianjin, Shandong and Anhui respectively. By purchasing raw materials and dispatching personnel, LYYD cooperates with factories to complete product production.In terms of technical services, we provide a full range of pre-sales, sales and after-sales services for brand operators.

Including: product selection, competition PK, use process, dilution and blending content, so that brand users can focus on marketing, at the same time in product quality in an advantageous position. Form highly "specialized division of labor" cooperation mode, obtain long-term, sustainable and stable competitive advantage.

Lingzhi Liaoyuan (Beijing) Energy Conservation and Environmental Protection Technology Research Institute (hereinafter referred to as Lingzhiyan) is located in Yizhuang Economic and Technological Development Zone, Beijing. At present, it is the only independent research and development institution of automobile maintenance chemicals in China, and has extensive influence in the industry. There are 6 R&D project groups under the research institute, mainly Carry out research and development of related products such as engine-free cleaning, oil additives, car cleaning and beauty, industrial and mining cleaning and protection, involving basic research, material synthesis, formula design and instrument development and other professional fields.

Hot Searches