- Product Details

- {{item.text}}

Quick Details

-

Ejector Force(kN):

-

77 kN

-

Theoretical Shot Volume(cm³):

-

929 cm³

-

Injection Rate (g/s):

-

700 g/s

-

Injection Weight (g):

-

845 g

-

Screw Speed (rpm):

-

1 - 150 rpm

-

Screw diameter (mm):

-

65 mm

-

Weight (KG):

-

9000 kg

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

570 mm

-

Power (kW):

-

22 kW

-

Product name:

-

4000 Ton Injection Molding Machine

-

Marketing Type:

-

New Product 2022

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

590mm

-

Distance between Tie Bars(Height)(mm):

-

610mm

-

Ejector Stroke(mm):

-

160 mm

-

Ejector Force(kN):

-

77 kN

-

Theoretical Shot Volume(cm³):

-

929 cm³

-

Injection Rate (g/s):

-

700 g/s

-

Injection Weight (g):

-

845 g

-

Screw Speed (rpm):

-

1 - 150 rpm

-

Screw diameter (mm):

-

65 mm

-

Weight (KG):

-

9000 kg

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

570 mm

-

Power (kW):

-

22 kW

-

Product name:

-

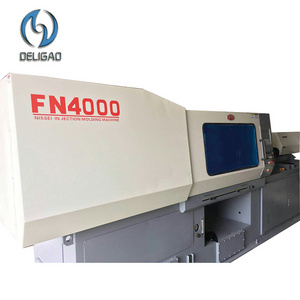

4000 Ton Injection Molding Machine

-

Marketing Type:

-

New Product 2022

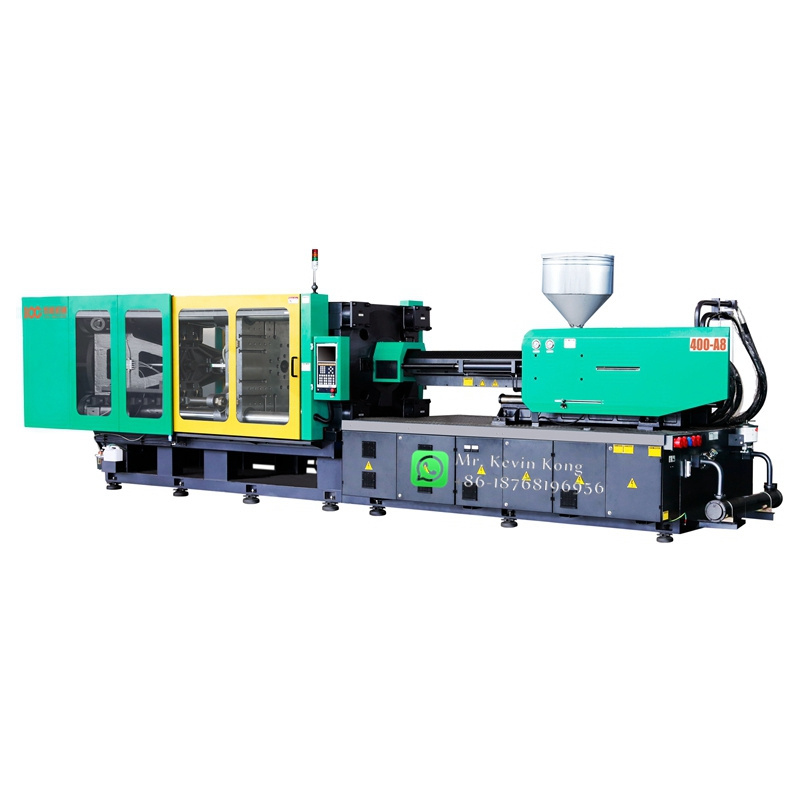

4000 Ton Injection Molding Machine

Contact: Mr. Kevin Kong

Mobile&WhatsApp&Wechat: +86-18768196956

| LOG PLASTIC INJECTION MOLDING MACHINE | ||

|

MODEL

NO. |

Tie-Bar

Distance (mm) |

B Screw

Injection Weight (g) /PS |

| LOG-90 | 360X360 | 144 |

| LOG-110 | 405X370 | 175 |

| LOG-130 | 410X410 | 239 |

| LOG-160 | 460X460 | 298 |

| LOG-210 | 510X510 | 429 |

| LOG-250 | 560X530 | 625 |

| LOG-300 | 610X590 | 845 |

| LOG-320 | 710X655 | 1120 |

| LOG-400 | 770X705 | 1646 |

| LOG-500 | 830X830 | 1919 |

| LOG-650 | 930X900 | 2488 |

| LOG-800 | 1030X940 | 2907 |

| LOG-900 | 1080X1030 | 3571 |

| LOG-1100 | 1150X1100 | 5403 |

LOG MACHINE is located in the kingdom of china plastic products—Yuyao. It’s a professional enterprise of high-tech injection molding machine. Since LOG officially came out to the market, the company's sales network has already throughout the world and has set up more than 50 dealers in mainland China ;Also set up distributors and service stations in more than 20 overseas countries such as in North and South America, in the Commonwealth of Independent States, in Southeast Asia, in Africa, in the Middle East, and as well as in the European region.

Factory land area: more than Production capacity :mroe thans

100000 4000

square meters sets

Machine Features

Dual-cylinder balanced injection system

Dual-cylinder base moving

Multi-stage injection Pressure/Speed & Position Control

Multi-stage stroing pressure, speed & position control

High-torque Oil Motor Drive Screw Preplasticizing device

Hopper temperature control by computer PID

Ceramic Hopper Heating Device

Hopper cooling system

Screw speed testing device

Super Energy Saving

40% more energy efficient than the variable pump system. 60% energy saving than the fixed pump + fixed speed motor (depending on the product can not save energy)

High Precision, High Response

The high-precision, high-sensitivity pressure sensor and rotary encoder realize closed-loop control of pressure and flow, and the repeat progress error is less than 1%. The servo motor reaches the maximum output power in only 0.05 seconds.

Low Noise

The noise value is within 78 db. When the machine is not operating, the servo motor stops almost no noise.

Save Cooling Water

Overflow heating of the non-quantitative pump + fixed speed motor system. Low temperature of hydraulic oil, greatly reducing the amount of cooling water

New Clamping Structure

The involute five-point elbow type clamping mechanism, the connecting rod and template of the cast-connected structure strengthened by finite element analysis effectively reduce the stress and deformation, and improve the rigidity and precision of the clamping part

New Power Composition

The servo motor, servo drive, pressure sensor, rotary encoder, gear pump and high-precision injection molding machine special injection molding controller constitute a new power system, so that the energy demand of the injection molding machine is best matched.

Contact us: