- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

customed

-

Power:

-

customed

-

Weight (KG):

-

15000

-

Powder coating line:

-

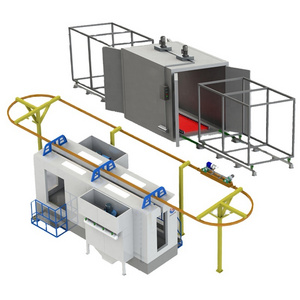

Power and Free Conveyor Powder Coating Line Machine

-

Powder coating booth:

-

Pass through type

-

Application:

-

Metal Surface Coating

-

Powder coating machine:

-

Electrostatic

-

Coating film:

-

20-80um

-

Control System:

-

SIEMENS PLC+Touch Screen Automatic

-

Powder coating oven:

-

Gas;Electric;Diesel

-

Usage:

-

Automatic Powder Coating System

-

Powder recycle system:

-

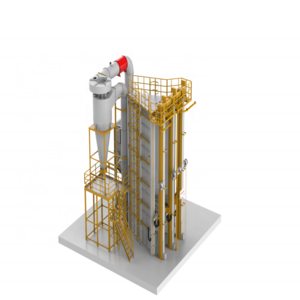

Cyclone Powder Recycle System

-

After-sales Service Provided:

-

Field installation, commissioning and training

Quick Details

-

Machine Type:

-

cnc, Spray Booths, Painting Equipment, Plc Controller Programmable Logic Controller, Pre-treatment Equipment, Conveying Equipment, Drying Oven, Curing oven, Coating Equipment, Anodized Equipment, Sandblasting Machine, Powder coating line, Powder coating booth, Powder coating system, Metal coating machinery

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Hanna

-

Voltage:

-

customed

-

Power:

-

customed

-

Weight (KG):

-

15000

-

Powder coating line:

-

Power and Free Conveyor Powder Coating Line Machine

-

Powder coating booth:

-

Pass through type

-

Application:

-

Metal Surface Coating

-

Powder coating machine:

-

Electrostatic

-

Coating film:

-

20-80um

-

Control System:

-

SIEMENS PLC+Touch Screen Automatic

-

Powder coating oven:

-

Gas;Electric;Diesel

-

Usage:

-

Automatic Powder Coating System

-

Powder recycle system:

-

Cyclone Powder Recycle System

-

After-sales Service Provided:

-

Field installation, commissioning and training

Product Description

Automatic Overhead Conveyor Electrostatic Spray Powder Coating Painting Production Line

1. Advantages of automatic spraying: When the automatic spraying production line is used for a large number of single workpieces, it can greatly reduce labor costs and energy consumption, has a larger daily production capacity, lower investment than automatic spraying equipment, and less equipment maintenance costs.

2. Advantages of fully automatic spraying: The quality of the workpieces sprayed by the fully automatic spraying production line is stable, and when mass spraying produces the same workpiece, it has a considerable output advantage because compared to manual spraying, semi-automatic spraying, For automatic spraying, energy consumption and labor costs can be greatly reduced, thereby greatly reducing spraying costs.

Case Stories

Let us show and tell

The full powder coating line is specially designed and manufactured by Hanna for Bulgaria customer, they Powder coating for the aluminium panel, supermarket and shopping mall storage equipment and aircraft parts. They are the biggest manufactures in Balkan Peninsula.

The full powder coating line is specially designed and manufactured by Hanna for Bulgaria customer, they Powder coating for the aluminium panel, supermarket and shopping mall storage equipment and aircraft parts. They are the biggest manufactures in Balkan Peninsula.

For more project cases, welcome contact us...

Application

ALUMINUM PROFILES WINDOWS

STORAGE EQUIPMENTS

METAL CABINET/FURNITURE

Detailed Picture

Powder coating booth

The powder coating booth is made of anti stick powder material, the recovery model can chose cyclone and filter type.

Powder coating oven

The powder coating oven is made of 150mm thickness insulation rock wool.We can chose gas, diesel, electric as heating fuel.

|

Powder coating booth type

|

|

|

Pass through

|

|

|||

|

Material

|

|

|

PVC or PP

|

|

|||

|

Size

|

|

|

L6.5m*W1.5m*H3m (Accept customized)

|

|

|||

|

Recovery system

|

|

|

Filter direct recovery or cyclone recovery

|

|

|||

Certifications

About Us

Since 1990,From simple manual spraying to automatic powder spraying system.

We can provide you with innovative, rational and economical solutions. We can support you with advanced technologies.Delivering the best powder coating equipments and turn-key solutions.

We’ve built thousands of optimal customized lines and systems for powder coating operations across China

and around the world.

Our continuous research on the field as well as our constantly developing techniques and innovative nature

of our engineering dpt. enable our customers to catch up to the latest developments by modernizing their

equipment partly or wholly, so as to improve performance, increase profits and maintain their

competitiveness in the world of trade.

Our company has passed ISO9001 certification,CE certification, and has obtained more than 70 paten.

We can provide you with innovative, rational and economical solutions. We can support you with advanced technologies.Delivering the best powder coating equipments and turn-key solutions.

We’ve built thousands of optimal customized lines and systems for powder coating operations across China

and around the world.

Our continuous research on the field as well as our constantly developing techniques and innovative nature

of our engineering dpt. enable our customers to catch up to the latest developments by modernizing their

equipment partly or wholly, so as to improve performance, increase profits and maintain their

competitiveness in the world of trade.

Our company has passed ISO9001 certification,CE certification, and has obtained more than 70 paten.

Our Hanna company is based on the Chinese domestic market, It started in 1990. Many listed companies and foreign companies in the Chinese market are our powder coating equipment users, Thousands of electrostatic spray powder coating line project all over the world. Good quality and best service make us enjoy the high reputation in the surface finish treatment field. We focus on the output of large-scale powder coating lines and turnkey solutions. Over the years, we have accumulated rich experience in full electrostatic paint coating line solutions.

Packing&Shipping

FAQ

Are you a trader or a factory?

We are manufacturer and exporter. Our own factory was found in 1990,Our export office was established in 2014.

What should I provide if interested in your powder coating equipment ?

A.The material/size(max)/weight(max)of your workpiece.

B.How many of your daily output(one day=8hours,one month=30days)?

C.What heating power do you prefer: electric,gas, diesel or coal?

D.The size of your factory(length, width and height)?

How to ensure the quality of the equipment?

A,We have hundreds of patents and passed the IS9001:2015 quality management system certification.

B,The Technical Review Committee,reasonably determines and divides the stages of design, production, installation and commissioning, and formulates detailed progress plans for each stage, Strengthen the quality assurance system and quality protection measures of equipment manufacturing department.

C,We manning quality inspectors specially to control the processing quality of product strictly.

How to install equipment after purchasing your equipment?

A,We will provide installation information and installation videos

B,Our engineers will guide the installation and run the equipment.

C,After the debugging, will provide complete training and track customer device usage.

How is your company's after-sales service done?

A,Provide the list of consumables to assist customers in establishing a

comprehensive equipment maintenance system.

comprehensive equipment maintenance system.

B,After the equipment is delivered to the customer, our company will send professionals to track the customer equipment for 60 days.

C,If customer has a device failure in the process of using the device,our company will operate the device remotely through the computer network through the authorization given by the customer, and eliminate all equipment failure problems. D,Any problems with the equipment, our company guarantees to give solutions within 12 hours.

Hot Searches