- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Voltage:

-

Customized

-

Name:

-

Aluminum Plastic Laminated Tubes Production Line

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

Automatic Grade:

-

Automatic

-

Function:

-

ABL and PBL tube

-

Color:

-

Can be designed as you want

-

Tube Types:

-

Aluminum-plastic tube and Plastic Tube

-

Usage:

-

Plastic Forming Machine

-

Warranty:

-

1 year, 1 Year

-

Suitable material:

-

ABL PBL Sheet

-

Product:

-

ABL, PBL Laminated Sheet

-

Product Type:

-

Laminated Tube

-

Key Selling Points:

-

Easy to Operate

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Applicable Industries:

-

Hotels, Manufacturing Plant, Food & Beverage Factory, Restaurant, Home Use, Printing Shops

-

Local Service Location:

-

None

-

Showroom Location:

-

None

-

Processing Type:

-

Other

-

Certification:

-

ISO9001:2008

-

Power (kW):

-

5.7KW

Quick Details

-

Brand Name:

-

Sunway

-

Dimension(L*W*H):

-

4810*870*1700mm

-

Weight:

-

3000kgs

-

Place of Origin:

-

China

-

Voltage:

-

Customized

-

Name:

-

Aluminum Plastic Laminated Tubes Production Line

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

Automatic Grade:

-

Automatic

-

Function:

-

ABL and PBL tube

-

Color:

-

Can be designed as you want

-

Tube Types:

-

Aluminum-plastic tube and Plastic Tube

-

Usage:

-

Plastic Forming Machine

-

Warranty:

-

1 year, 1 Year

-

Suitable material:

-

ABL PBL Sheet

-

Product:

-

ABL, PBL Laminated Sheet

-

Product Type:

-

Laminated Tube

-

Key Selling Points:

-

Easy to Operate

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Applicable Industries:

-

Hotels, Manufacturing Plant, Food & Beverage Factory, Restaurant, Home Use, Printing Shops

-

Local Service Location:

-

None

-

Showroom Location:

-

None

-

Processing Type:

-

Other

-

Certification:

-

ISO9001:2008

-

Power (kW):

-

5.7KW

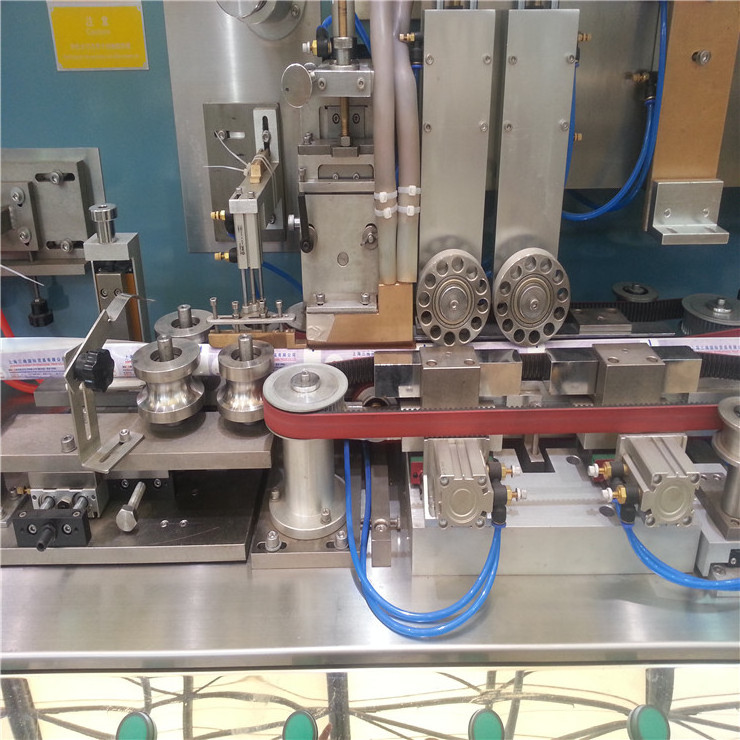

B.GLS-III Aluminum-plastic laminated tube machine

This machine can make Aluminum-plastic tube and Plastic tube.

The B.GLS-III model aluminum-plastic laminated tube machine is successfully researched and developed by our company through absorbing internationally advanced technologies on the basis of the first generation tube machine. The machine is mechanically, electrically and pneumatically integrated. Compared with other products of its kind at abroad, it has such features as low investment, high efficiency, low energy consumption, easy operation, stable performance, simple maintenance, etc.

B.GLS-III Aluminum-plastic laminated tube machine uses aluminum-plastic laminated sheets and full-plastic laminated sheets as the materials and adopts high frequency welding technology for producing various specifications of laminated tubes. The products produced are featured by flat and firm weld seams, precise and beautiful cutting etc.

By adopting the device of sheet replacement without machine stopping, it is featured by the highest sheet utilization rate, the lowest labor intensity, safe use, etc.

B.GLS-III Aluminum-plastic laminated tube machine unit is mainly composed of automatic unwinder, connection platform, automatic edge cutting device, automatic deviation correcting system, automatic forming device, high frequency welding device, vertical and horizontal dragging devices, automatic control and tracking rotary cutting device, man-machine interface control system, etc.

The machine has been granted 6 national patents with patent numbers 02219950.0; 002119963.7; ZL200520077446.0; ZL200620071770.6; ZL200520077451.1;ZL200520077448.X; ZL200520077447.5.

Main Technical Parameters

|

Machine main motor power |

2.2 kw |

|

Cutter motor power |

1.0kw |

|

High frequency welding power |

2 kw |

|

Other welding power |

0.5kw |

|

Input power supply |

380(220)V/50Hz |

|

Max.production capacity |

150pcs/min |

|

Dimension(L*W*H) |

4810*870*1700mm |

|

Weight |

3000(kg) |

|

Differences between B.GLS-III and B.GLS-I V |

||

|

|

B.GLS-III |

B.GLS-I V |

|

1 |

Whole Stainless Steel |

Painting powder, iron frame |

|

2 |

Make both ABL and PBL tube |

Only ABL tube |

|

3 |

Pulling, welding &cutting speed adjusted by PLC, High frequency goes automatically |

High frequency and pulling, welding & cutting speed adjusted separately |

|

4 |

Wheel pulling, no damage of web |

Belt pulling |

|

5 |

With two welding system of High frequency(ABL) & Electric + metal belt(PBL) |

With High frequency system(ABL) |

|

6 |

With web storage box Non-stop machine to change web roll |

Stop machine to change web roll |

|

7 |

High using efficiency of web(1.8% wastage) |

3% web wastage |

|

8 |

More stable |

|

|

9 |

Longer running life |

|

1. After-sale-service

2. Engineer will go to customer factory to install and test machines

3. Help customer change the semi-automatic line to be automatic line

4. Design the machines connection according with the area of factory 5. Help to train the worker to let them can produce qualified tube