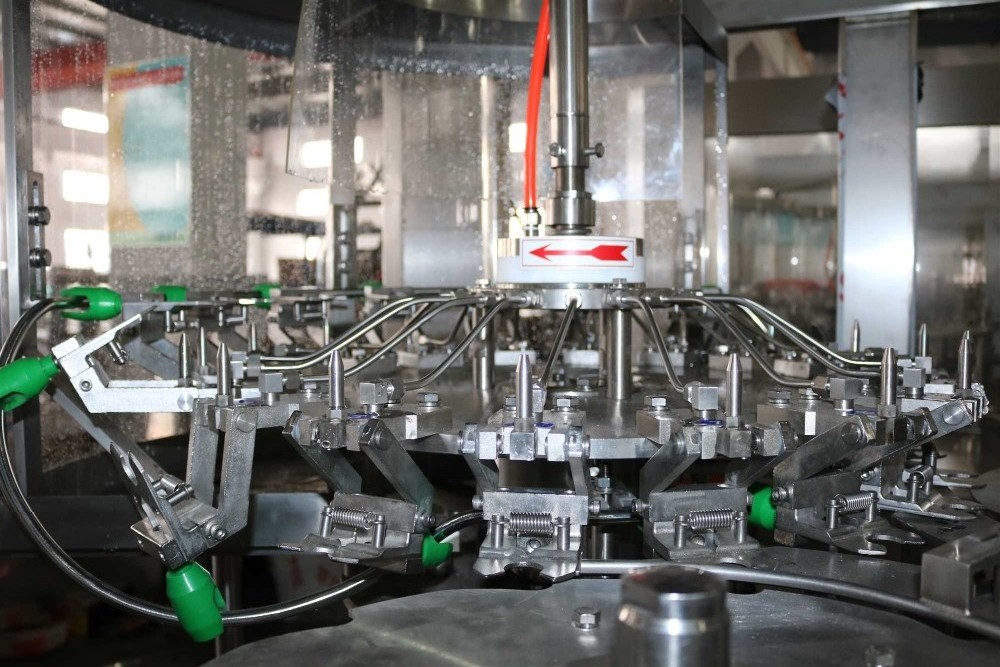

<1>Into bottle way is air conveyor direct connection with Bottle dial .

<2>All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean .

<3>304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

<4> 304/316 stainless steel washing pump make the machine more durable .

- Product Details

- {{item.text}}

Quick Details

-

Capacity:

-

4000-35000BPH

-

Material:

-

SUS304/SUS316

-

Filling temperature:

-

Hot filling

-

Processing:

-

Washing,Filling,Capping

-

Structure:

-

Rotate

-

Bottle diameter:

-

50-90mm

-

Electric element:

-

Siemens&Schneider or by order

Quick Details

-

Packaging Material:

-

Wood

-

Place of Origin:

-

Jiangsu, China

-

Controlled by:

-

PLC (MITSUBISHI)

-

Capacity:

-

4000-35000BPH

-

Material:

-

SUS304/SUS316

-

Filling temperature:

-

Hot filling

-

Processing:

-

Washing,Filling,Capping

-

Structure:

-

Rotate

-

Bottle diameter:

-

50-90mm

-

Electric element:

-

Siemens&Schneider or by order

Product Application

This series of machine is specially apply to PET bottle carbonated drink filling,it combine with the function of washing filling capping in one machine.It is mainly used for washing,filling,capping for carbonated water,cola,sparkling,water etc carbonated beverage.Reasonable structure,safely operation,reliable operation,easy maintenance.Transform bottle adopt block bottle neck technology,no need to adjust equioment level when change different type bottles,simple replace with the bottle mouth,bottle diameter related arc guide plate,dial etc.Stainless steel washer bottle clip durable,do nottouch bottle screw part,to avoid secondary pollution bottle.And material contact parts are made of food-grade stainless steel,no process corners,easy to clean.Pneymatic diaphragm valve controls flow of material into the liquid to ensure filling accuracy.Open the valve mechanism driven by the cylinder,accurate an reliable.Tell high flow,high precison filling valve,filling fast,accurate and no liquid surface damage.Capping head adopts constant torque magnetic device to ensure capping quality,and will not damage the cap.Cover with efficient management system with perfect cap feeding and lack of cover protection devices.A complete overload protection devices,can effectvely protect the equipment and operator safety.

|

Model

|

DCGF 16-12-6

|

DCGF 18-18-6

|

DCGF 24-24-8

|

DCGF 32-32-10

|

DCGF 40-40-12

|

|

Rinsing heads

|

16

|

18

|

24

|

32

|

40

|

|

Filling heads

|

12

|

18

|

24

|

32

|

40

|

|

Capping heads

|

6

|

6

|

8

|

10

|

12

|

|

Capacity(BPH)

|

3000

|

5000

|

7000

|

10000

|

|

|

Power(KW)

|

2.2

|

3.5

|

4.5

|

6

|

|

|

Dimensions(mm)

|

2300*1600*2500

|

2600*1920*2550

|

3100*2200*2800

|

3560*3000*2850

|

|

|

Weight(KG)

|

2800

|

3650

|

4800

|

6800

|

|

Washing heads.

Filling heads.

<1> 304/316 Stainless steel high precision filling nozzle

<2> Filling volume adjustable in fine rank, same liquid level after filling

<3> All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

<4> 304/316 stainless steel filling pump

<5>Efficient spray nozzle rinse thoroughly and save water for flushing

Capping heads.

<1> Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

<2> All 304/316 stainless steel construction

<3> No bottle no capping

<4> Automatic stop when lack of bottle

<5>Capping effect is stable and reliable ,Defective rate ≤0.2% .