We are factory,we can the same quality machine with a lower price.

Henan Chengjinlai Machinery Manufacturing Co., Ltd. is a professional manufacturer of charcoal manufacturing machinery in China.

Continuous improvement and innovation is our production philosophy. Our tenet: Survive by quality, develop by credit, quality

first, credit first, integrity-based, customer first.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

ZZL-500,ZZL-1000,ZZL-2000

-

Marketing Type:

-

New Product 2023

-

Weight (KG):

-

5000 kg

-

Application:

-

Lithium Battery Manufacturer

-

Raw material:

-

Used Lithium Ion Battery

-

Final product:

-

Lithium Cobalt Powder

-

Product name:

-

Waste Battery Recycling Machine

-

Keywords:

-

Lead Battery Dismantling Machine

-

Voltage:

-

220V/380V/Customized

-

Application field:

-

All Kinds Of Lithium Batteries

-

Feature:

-

High Seperation Ratio

Quick Details

-

Production Capacity:

-

300-2000kg/h

-

Place of Origin:

-

HENAN

-

Brand Name:

-

ZHUOZHILAN

-

Model Number:

-

ZZL-500,ZZL-1000,ZZL-2000

-

Marketing Type:

-

New Product 2023

-

Weight (KG):

-

5000 kg

-

Application:

-

Lithium Battery Manufacturer

-

Raw material:

-

Used Lithium Ion Battery

-

Final product:

-

Lithium Cobalt Powder

-

Product name:

-

Waste Battery Recycling Machine

-

Keywords:

-

Lead Battery Dismantling Machine

-

Voltage:

-

220V/380V/Customized

-

Application field:

-

All Kinds Of Lithium Batteries

-

Feature:

-

High Seperation Ratio

Product Description

BRIEF INTRODUCTION:

Lithium battery mainly consists of

shell, positive electrode, negative electrode, electrolyte and diaphragm

. The positive electrode is formed by coating lithium cobaltate powder on two sides of an aluminum foil current collector through PVDF which plays a bonding role; The negative electrode structure is similar to the positive electrode and consists of carbon powder bonded to both sides of the copper foil current collector.

The pretreatment process of lithium battery recycling machine mainly comprises

the following steps

: after discharging the recovered waste batteries, crushing, magnetic separation, air separation, crushing, gravity separation, screening and other processes are carried out by mechanical equipment.

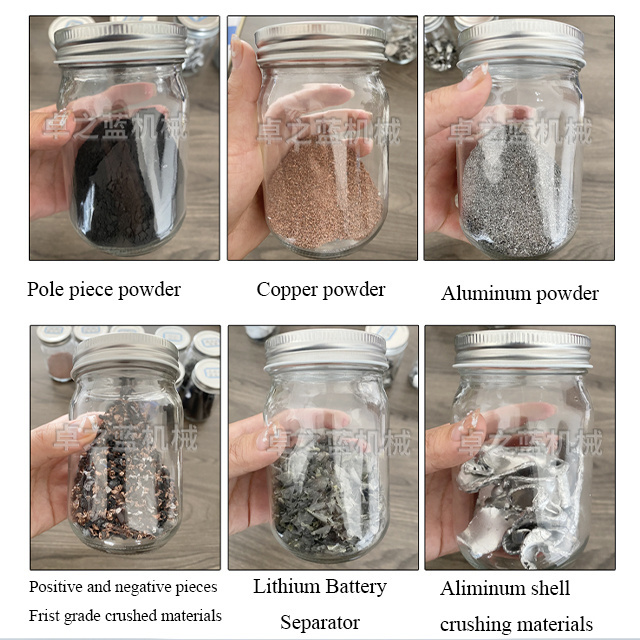

Raw Materials & Finished Products

The Lithium Ion Battery Recycling Machine is used for dismantling and recycling the soft package battery, cellphone battery, shell battery, cylindrical battery etc. Different types of lithium batteries have different recycling procedures.

The final products of Battery Lithium Ion Battery Recycling Machine is

graphite powder, cobalt acid lithium,aluminum and copper.

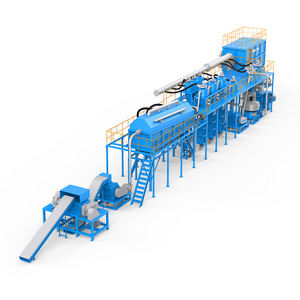

Production Line

Lithium battery recycling separation process:

(1)The raw material shall be crushed by the first crushing machine. (30~100mm)

(1)The raw material shall be crushed by the first crushing machine. (30~100mm)

(2) Be delivered to the second crushing machine by the sealed conveyor. (2~5mm)

(3) The crushed material will be delivered into the air separator by high pressure air conveyor, it will be separated into rough powder and small powder and septum. The small powder enters the cyclone discharging device, the rough powder enters the vibrating screen.(air speed and air pressure precisely controlled by the transducer )

(4) The material which enters the cyclone discharging system will be delivered to the vibrating screen by the air conveyor, copper granule, aluminum granule, and lithium cobalt mixture powder will be separated from it, and as well as the septum powder.

(5) The rough powder contains more metal, it will be delivered to the vibrating screen via the high pressure air conveying system, the lithium cobalt mixture powder and copper/aluminum powder will be separated out.

(6) The final separating system is our air gravity separator, it can separate the lithium cobalt and copper and aluminum totally.

(7) The whole plant is running under the vacuum condition to avoid the dust pollution and leakage of the lithium cobalt.

Shredder -- Hammer Crusher -- Grinder -- Separation Machine -- Pulse Dust Collector -- Classifying Screen -- Magnetic Machine -- Gravity Separator -- High-pressure Blower

For more details you can contact us.

Specification

|

WORKING PERFORMANCE

|

|

|

|

Raw Material

|

Lithium Battery

|

|

|

Final Product

|

Mainly Copper, Aluminum, Lithium Cobalt Oxide, Graphite Powder

|

|

|

Technical Parameters

|

|

|

|

Mold

|

Capaticy

|

|

|

ZZL-300

|

300 kg/h

|

|

|

ZZL-500

|

500kg/h

|

|

|

ZZL-800

|

800 kg/h

|

|

|

ZZL-1000

|

1000 kg/h

|

|

|

ZZL-1500

|

1500 kg/h

|

|

|

ZZL-2000

|

2000kg/h

|

|

|

Working voltage:380ᄆ10V

|

1 Year

|

|

|

Feature Item

|

Indicator Requirments

|

|

Recovery Rate of Metallic Aluminum

|

>98%

|

|

Content of Powder In Metal Aluminum

|

>98%

|

|

Content of Metallic Aluminum In Powder

|

<2%

|

|

Other

|

<2%

|

|

Qualified Rate

|

Contain dust collecter with not pollute

|

|

Failure Rate

|

99%

|

|

Failure Rate

|

<1%

|

|

CMR

|

≥1.67

|

Real Shot Display

Packing & Shipping

We have 20 years delivery experience,so you don't need to worry about the damage during the transport.

Why Choose Us ?

1.FACTORY ADVANTAGE:

2.CERIFICATE

We have obtained many

cerification

,so you don't need worry about the quality of our machine.

3.CUSTOMER VISIT

Until now, we have customers more than 130 countries, Indonesia, India, Malaysia, Laos, Myanmar, Thailand, Vietnam,Philippines,Pakistan, Sri Lanka, Lebanon, Georgia, Turkey, Poland, Czech, Mongolia, South Korea, Romania, Egypt, Sudan, Tunis,Algeria, Ethiopia, Tanzania Equatorial Guinea, Zambia, Mexico, South Africa, etc.

You're welcome if you'd like to visit our factory! You can contact us now!

You're welcome if you'd like to visit our factory! You can contact us now!

FAQ

Q: What about the quality of your products?

A: Our machines are manufactured strictly according to national and international standards,and we take tests on each equipment before delivery.You can also use Trade Assurance by Alibaba for product quality protcction, on-time shipment protection and payment protection.

Q: How about the price?

A: We are manufactory, and we can give youlower price than those trade companies. Besides,customers from Alibaba can get a discount.

Q: How can I visit your factory?

A: You can come here by air or train. The nearest airport is Zhengzhou Xinzheng International Airport, and the Airport Code is CGO.

We will pick you up at airport. Welcome to visit our factory.

Hot Searches