By order default,choose in this!Colors can be customized.

- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

Lifetime warranty

-

Material:

-

Aluminum,6061-T6 Aluminum Alloy

-

Model Number:

-

X83

-

Product Name:

-

Alumilum Alloy Wheel

-

Keyword:

-

Customized Forged Car Wheels Rims

-

Technology:

-

12000T High Pressure/CNC

-

Type:

-

Aftermarket Forged Wheels

-

Quality:

-

High Performance Wheels

-

Style:

-

Luxury Customized Forged

-

Size:

-

15-26 Inch

-

Color:

-

Customizing Color

-

Car Make:

-

Brand Cars

-

Certification:

-

TUV/JWL/VIA

Quick Details

-

Finishing:

-

So color, polishing, plating, drawing

-

Width:

-

7J-14J

-

Place of Origin:

-

China

-

Warranty:

-

Lifetime warranty

-

Material:

-

Aluminum,6061-T6 Aluminum Alloy

-

Model Number:

-

X83

-

Product Name:

-

Alumilum Alloy Wheel

-

Keyword:

-

Customized Forged Car Wheels Rims

-

Technology:

-

12000T High Pressure/CNC

-

Type:

-

Aftermarket Forged Wheels

-

Quality:

-

High Performance Wheels

-

Style:

-

Luxury Customized Forged

-

Size:

-

15-26 Inch

-

Color:

-

Customizing Color

-

Car Make:

-

Brand Cars

-

Certification:

-

TUV/JWL/VIA

Products Description

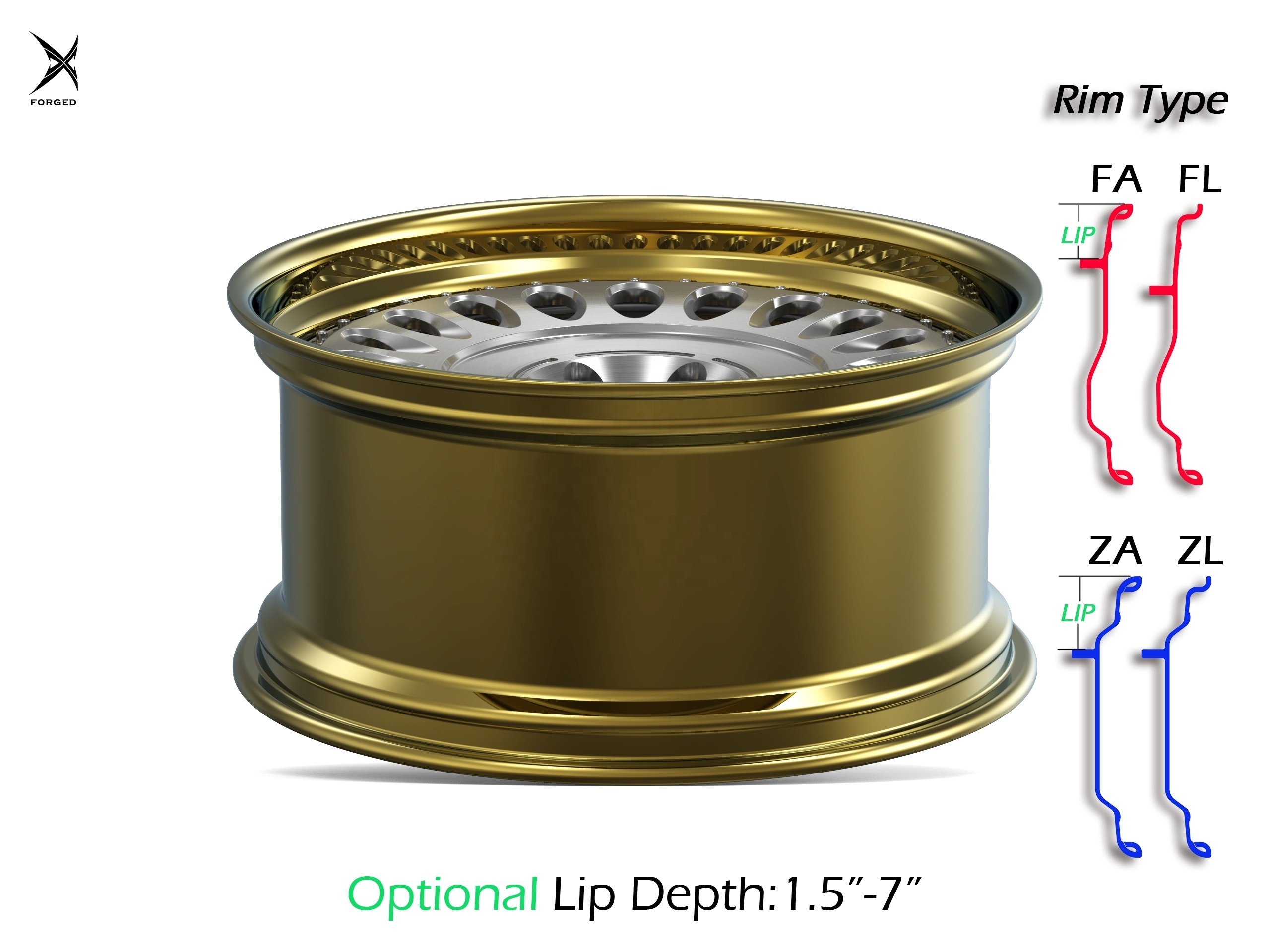

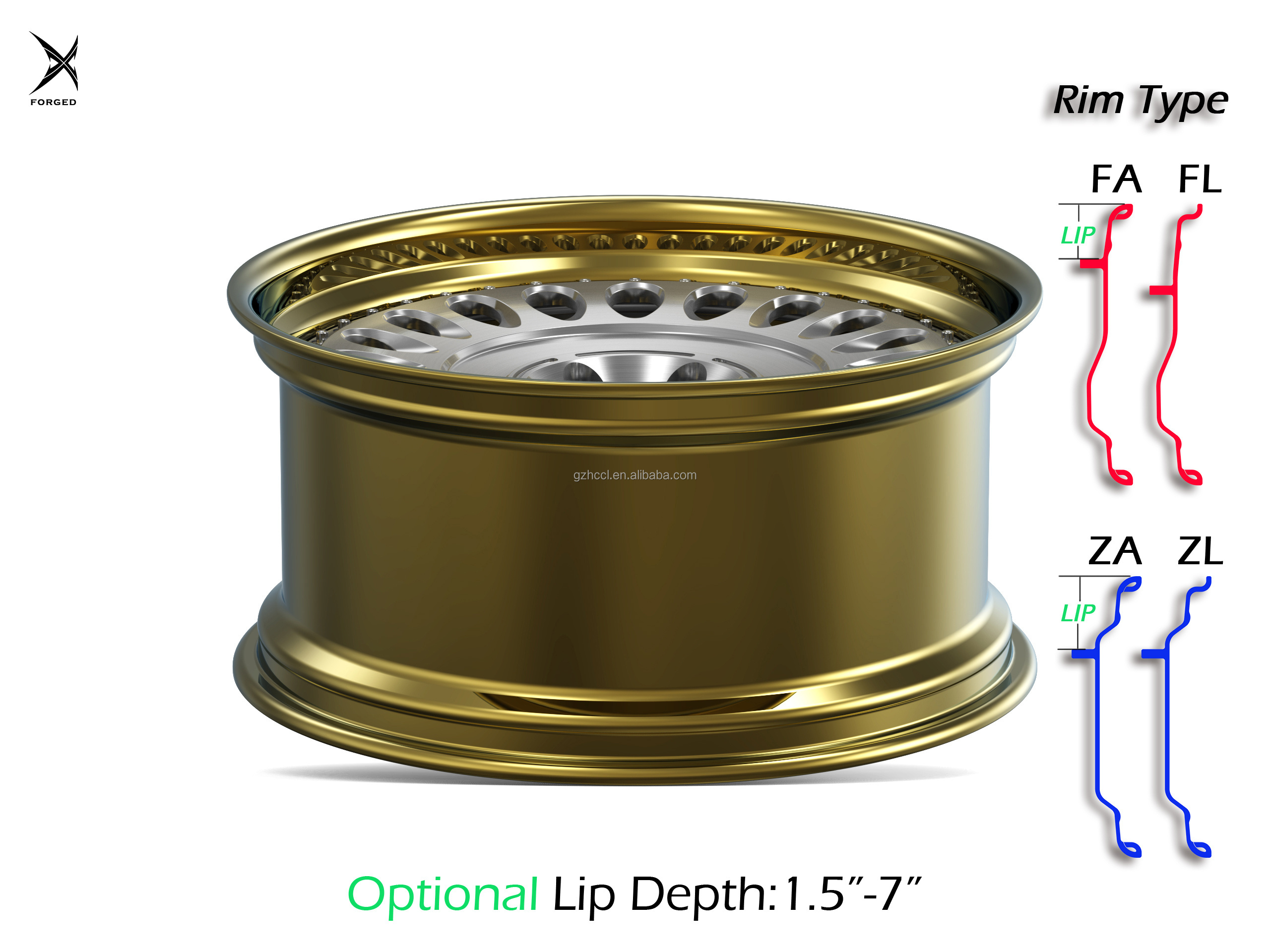

2 piece forged wheels aluminum alloy 6061-T6 and 6082-T6 with Ultimate Design、

Luxury、 High Performance、 Lightweight.

U2B Ultra Lightweight Two Piece Aluminum Forging Barrel Product summary 6082 T6 Patented

U2B Barrel Technology

The shaping process used on U2B adopts the high-end aluminium forging technology, dramatically improved the mechanical property. It is the most advanced technology in the wheel industry as the real high-end ultra-light two-piece barrel (U2B) is achieved. An edge on the inside of rim was formed by single shaping technique; it increases the rim strength and also provides the base for centre disk installation. The edges of the rim are the most important parts as they support the tyre, but they also are the weakest parts; in order to increase the strength factory used edge-rolling technique therefore has dramatically increased the strength (same as the top edge of Coca Cola can). U2B has realised the innovation on wheel structure. All of these new inventions will replace the traditional production method.

Product Advantage

U2B Barrel has assembled the rim and spokes completely by using its unique production and compound technologies. Same spoke can be assembled with different width and colour rim to form a two-piece alloy wheel, it increased the level of individual character products. This product has passed the test undertaken by National Automobile Wheel Quality Supervision and Inspection Centre. This two-piece forged alloy wheel was designed against the high performance and big brake drum vehicles, rim width can reach 14 inches, this cannot be achieved by traditional casting wheel. The innovated technology used on the rim structure can reduce the wheel weight by 15% -20% compare to the traditional method, it therefore dramatically improved the material performance. It has below featured increase material performance; attractive exterior design; durable; ultra-light can save petrol and also reduce the CO2 emission and tyre wear and tear. The brake distance can also be reduced by using wide tyre.

Products Properties

|

Size

|

Width(inch)

|

PCD(mm)

|

Hole

|

ET(mm)

|

CB(mm)

|

|

18"

|

7.5"~14"

|

100~150

|

4/5/6/8

|

-50~0~60

|

57.1~100

|

|

19"

|

8.5"~12"

|

100~150

|

4/5/6/8

|

-50~0~60

|

57.1~100

|

|

20"

|

8.5"~12.5"

|

100~150

|

4/5/6/8

|

-50~0~60

|

57.1~100

|

|

21"

|

8.5"~13"

|

100~150

|

4/5/6/8

|

-50~0~60

|

57.1~100

|

|

22"

|

8.5"~14"

|

100~150

|

4/5/6/8

|

-50~0~60

|

57.1~100

|

|

24"

|

9.0"~14"

|

100~150

|

4/5/6/8

|

-50~0~60

|

57.1~100

|

|

26"

|

9.0"~10"

|

100~150

|

4/5/6/8

|

-50~0~60

|

57.1~100

|

General Cap

Material:Aluminium Alloy

Luxury Cap

Material:Aluminium Alloy / Carbon Fiber

Luxury Cap

Customer specified options for a more advanced experience.

Unique Technology

The rim steps can be processed into a

zigzag shape

, which is unmatched by others, and can provide customers with a more advanced experience. We are also

the first

company in

China

that can make this product. This is achieved on the basis of U2B barrel

strong mechanical

properties.

Color Custom

The colors of rim and center disc can be customized. Customers can choose from several of our common standard colors, and for a more luxurious experience, we can offer

special paints

imported from

Germany

.

The following colors are for reference only, Please allow a little color difference in actual production.

Surface treatment methods are

brushed、gloss、matte、polished

, etc.

Ultimate Design

DESIGN

At this phase, we begin to implement the idea of the future wheel. We adapt the design outline to the technical characteristics of the car. Our technologies allow us to produce wheels with extreme designs and parameters without losing style and safety. We combine the versatility and creativity of design ideas with ubiquitous technological development and constant contact with the client. This approach allows you to not only guarantee the exclusivity of the design and reliability but also in the production process to make sure that the customer will receive exactly the wheels that he imagined

.

DESIGNING

Creating a wheel layout begins with analyzing the parameters of the car and fixing the maximum values allowed during production. Thus, you can be sure that the SKILL wheels can not only decorate the car but also improve the suspension characteristics. At this stage, a complete finite element analysis (FEA) is performed, taking into account curb weight, dynamic cornering fatigue, dynamic radial fatigue, and simulated impact tests in accordance with SAE, JWL, and VIA standards. After verification by our engineers, the final wheel model is sent to the customer for approval and programming for milling on the machines.

ENGINEERING

To guarantee the highest possible quality, strength, and durability of the wheels, we use the latest developments in the field of computer-aided design and testing. Detailed visualization, where you can see the distribution of stresses and displacements of the wheel, allows you to improve and optimize the layouts before production begins. We never compromise on quality, each of our projects meets the strict tests of the industry-recognized JWL standard. All these processes ensure that we provide our customers with the highest quality products.

Hot Searches