- Product Details

- {{item.text}}

Quick Details

-

Use:

-

remove stone heavy impurity from seed

-

Production Capacity (kg/h):

-

1000 - 1500

-

Sieve Size(mm):

-

1500*1500*1600

-

Power (kW):

-

9kw

-

Dimension(L*W*H):

-

2500*1500*1600

-

Weight:

-

900 KG

-

After-sales Service Provided:

-

Overseas service center available

-

Power:

-

7 KW

-

weight:

-

700kg

-

Material:

-

carbon steel

-

Function:

-

remove stone heavy impurity from seed

-

Voltage:

-

220v/ 380v/ 415V

-

Capacity:

-

10 tons per hour

-

dimension:

-

2500*2300*1600mm

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HOLYPHANT

-

Type:

-

seed destoner machine, seed destoner machine

-

Use:

-

remove stone heavy impurity from seed

-

Production Capacity (kg/h):

-

1000 - 1500

-

Sieve Size(mm):

-

1500*1500*1600

-

Power (kW):

-

9kw

-

Dimension(L*W*H):

-

2500*1500*1600

-

Weight:

-

900 KG

-

After-sales Service Provided:

-

Overseas service center available

-

Power:

-

7 KW

-

weight:

-

700kg

-

Material:

-

carbon steel

-

Function:

-

remove stone heavy impurity from seed

-

Voltage:

-

220v/ 380v/ 415V

-

Capacity:

-

10 tons per hour

-

dimension:

-

2500*2300*1600mm

millet rice cleaner and destoner wheat destoner machine

|

Model |

HOLYPHANT-D |

|

Capacity |

5000 kg/hour (count by wheat) |

|

Vibration motor |

1.5 Kw |

|

Air fan motor |

5.5Kw |

|

Dimension (L*W*H) |

2500×1560 x1600 mm |

|

Weight |

700 kg |

Function:

Function:

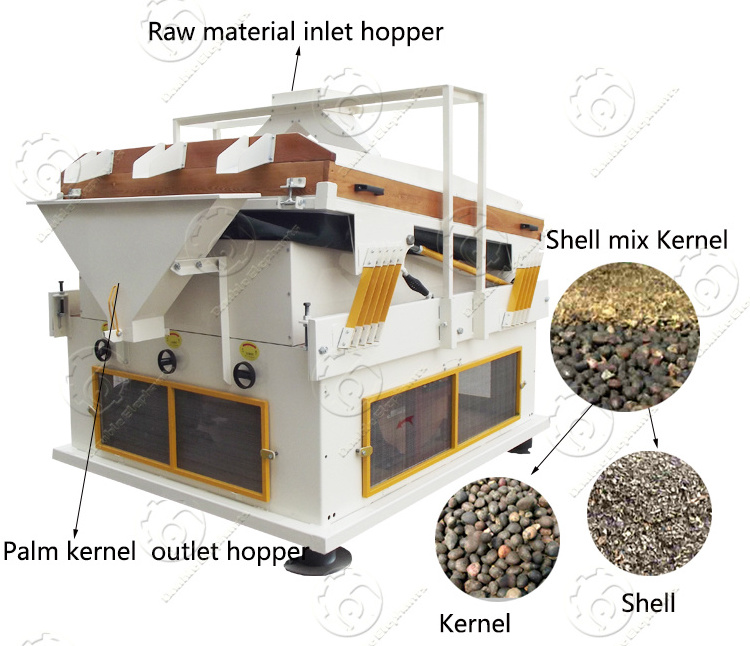

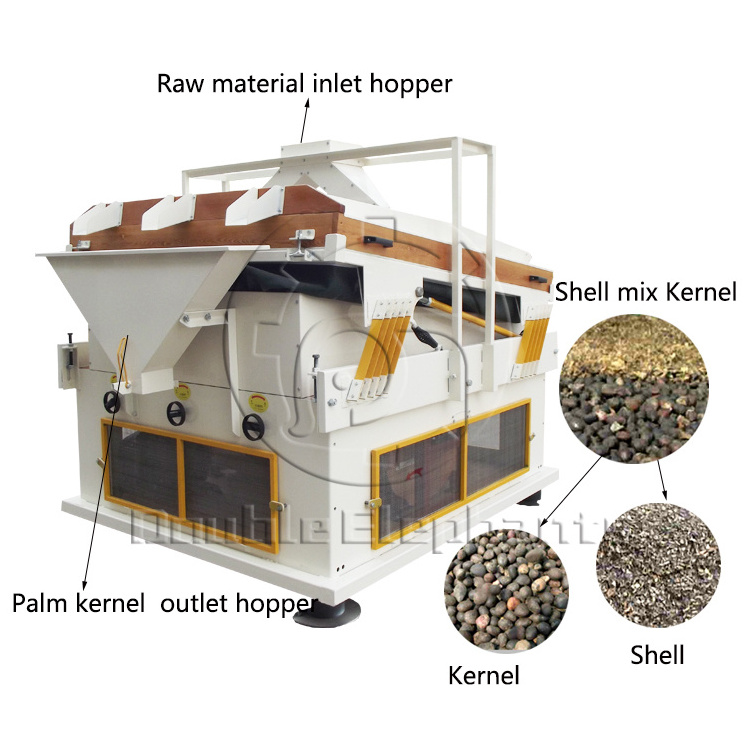

Destoner is used to remove the heavy density impurity (stones, sand, soil blocks) from raw material.

It is widely applied in all type grain seeds which are harvested from ground. Such as beans, wheat, corn, millet, ground nut, paddy etc.

5XQS series Destoner is air blowing type and having a big sieve bed. So it is a universal Destoner fits for all grain seeds processing. It is also easy to operate. Above advantages making it being a popular model in the world.

W orking principle:

Destoner is used to separat e granular product s where the particles are approximately the same size, but differs in weight . Via air blowing power and material mechanical movement, i t efficiently removes a small amount of heavy material from a larger quantity of light material. It can separate impurity like sand, stone, metallic and glass pieces from the grains. With the combination of fluidization and deck oscillation, heavy particles migrate to upper level, while light particles move to lower level of the deck.

Power control box

There is an invert er in the power control box. The invert can adjust motor speed and reduce starting current. When D estoner requires low vibration frequency , please adjust the invert to turn down the motor rotation speed. Please refer to the inverter instructions. Not frequently turn on or off the transducer to avoid damage equipment.

Air volume adjusting

T here are three air blowers in Destoner. Air volume adjusting handle connects the air blower directly. The air volume can be adjusted according to actual requirement. To check whether the a ir volume is appropriate, you should see the raw material distribution on sieve bed. If the air volume is suitable, the raw material should show a suspension on sieve bed . General ly, when suspend ing, the flow thickness is 30 ~ 40 mm for beans and 40 to 50 mm for white rice.

S ieve bed is 156 c m in width for Destoner

Destoner sieve bed has 3 openings on the high end as stones outlet and 1 big opening on low end as grain outlet.

Destoner sieve bed is made of hard wooden frame with stainless steel sieve layers. There are crosswise bars on bottom tray to carry the sieve layers.

S ieves ( It is made of one layer stainless steel mesh and one layer stainless steel screen )

There are 3 air blowers inside the 5XQS-5 Destoner. Please see following impeller photos.

High strength springs & spring plates, keep Destoner regular & steady vibration.

H igh standard material and skilled craft offering the best quality to you

We can offer dust cover for detoner, which is used in the grain cleaning plant as part of dust cleaning system.