- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

QRZ-8-12mm

-

Brand Name:

-

Qinrunze

Quick Details

-

Port Size:

-

2cm

-

Warranty:

-

1years

-

Place of Origin:

-

beijing

-

Model Number:

-

QRZ-8-12mm

-

Brand Name:

-

Qinrunze

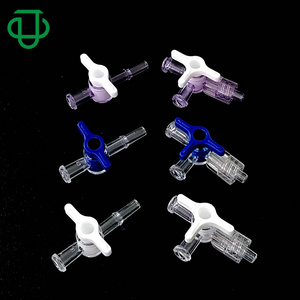

Specification model

3MM, 4MM, 5MM. 6MM 8MM 10MM 12MM The dimensions are: 3MM, 4MM 5MM 6MM 8MM 10mm. 12mm. Basically, none of our check valves can achieve the check function without pressure.

Note: 3mm 4mm 5mm 6mm 8mm 12mm (The valve body material is: polypropylene (PP); the valve core is silica gel; built-in 304 stainless steel spring)

Check valve characteristics

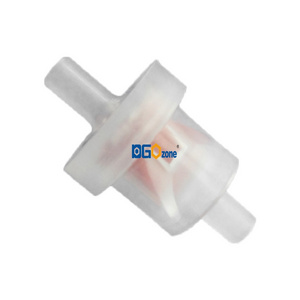

One-way valve is also called check valve or check valve. It is used to prevent the reverse flow of air and oil in pneumatic and hydraulic systems, or to prevent the reverse flow of compressed air in pneumatic systems.

Material characteristics

Polypropylene (PP) is a semi-crystalline thermoplastic. Has excellent comprehensive performance. When uncolored, it is white translucent and waxy. It has high impact resistance, strong mechanical properties, resistance to a variety of organic solvents and acid and alkali corrosion. Polypropylene resin has excellent mechanical properties and heat resistance, and its use temperature range is -30℃~140℃. At the same time, it has excellent electrical insulation properties and chemical stability, hardly absorbs water, and is insulated from most.

product description

One-way valve is also called check valve or check valve. Used to prevent the reverse flow of oil flow in hydraulic systems, or to prevent reverse flow of compressed air in pneumatic systems. There are two types of check valves: straight-through type and right-angle type. The straight-through check valve is installed on the pipeline with a threaded connection. Right-angle check valves have three forms: threaded connection, plate connection and flange connection. The hydraulically controlled check valve is also called the lock valve or the pressure maintaining valve. It is the same as the check valve to prevent the reverse flow of oil. However, when the oil flow is required to flow in the reverse direction in the hydraulic circuit, the control oil pressure can be used to open the one-way valve so that the oil flow can flow in both directions. The hydraulically controlled check valve adopts a tapered spool, so the sealing performance is good. When the oil circuit is required to be closed, this valve can be used as a one-way locking of the oil circuit to maintain pressure. There are two types of hydraulically controlled check valve to control oil leakage: internal leakage and external leakage. The internal drain type can be used in the oil circuit where the oil flow reverse outlet has no back pressure; otherwise, the external drain type is required to reduce the control oil pressure.

Hot Searches