- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

63

-

Power (kW):

-

7.5

-

Weight (KG):

-

2000

-

Name:

-

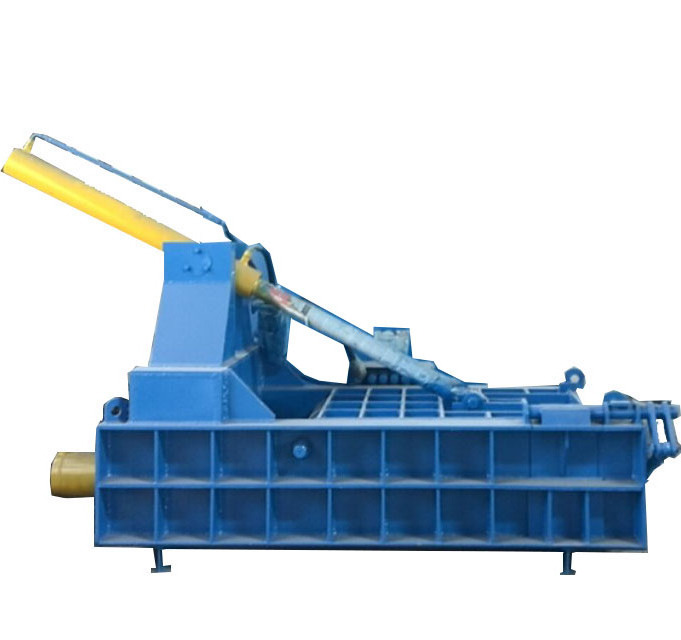

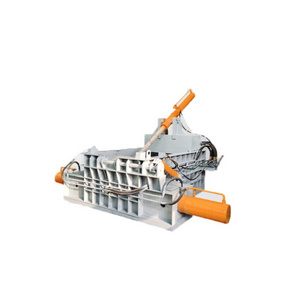

Scrap Metal Baler

-

Product name:

-

Used scrap metal compactor baler balling press machine prices

-

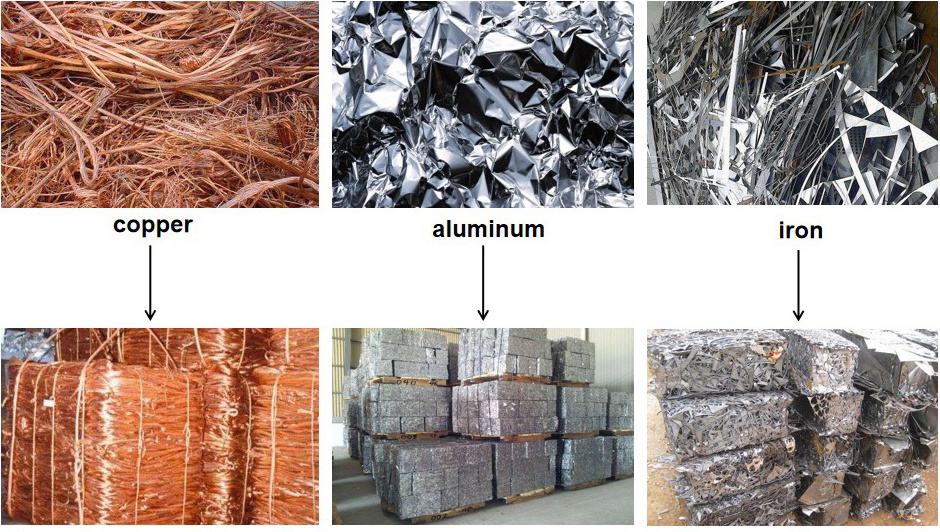

Application:

-

Metal block

-

Usage:

-

Metal

-

Color:

-

Blue,green,White

-

Certification:

-

ISO9001

-

Power:

-

7.5-45*2kw

-

Mold:

-

Ingot

-

Function:

-

Waste Metal Baling

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Mingxin

-

Marketing Type:

-

Hot Product 2023

-

Model Number:

-

63

-

Power (kW):

-

7.5

-

Weight (KG):

-

2000

-

Name:

-

Scrap Metal Baler

-

Product name:

-

Used scrap metal compactor baler balling press machine prices

-

Application:

-

Metal block

-

Usage:

-

Metal

-

Color:

-

Blue,green,White

-

Certification:

-

ISO9001

-

Power:

-

7.5-45*2kw

-

Mold:

-

Ingot

-

Function:

-

Waste Metal Baling

Features

|

Model

|

Nominal thrust

(kn)

|

Dimension of compress room

(mm)

|

Bale dimension (mm)

|

Bale weight

(kg)

|

Capacity

(t/h)

|

Power

(kw)

|

|

63

|

630

|

1000*600*500

|

190*190

|

15-30

|

0.4-0.8

|

7.5

|

|

100

|

1000

|

1000*700*550

|

230*230

|

30-40

|

0.6-1.2

|

11

|

|

125

|

1250

|

1200*700*600

|

300*300

|

50-75

|

1.2-1.5

|

15

|

|

135

|

1350

|

1400*600*600

|

600*240

|

60-80

|

1.5-2.8

|

22

|

|

160

|

1600

|

1600*1000*800

|

400*400

|

110-150

|

2.2-3.0

|

22

|

|

200

|

2000

|

1800*1400*900

|

450*450

|

210-300

|

3.0-5.0

|

22*2

|

|

250

|

2500

|

2000*1750*1200

|

500*500

|

250-280

|

5.0-6.3

|

22*2

|

|

315

|

3150

|

2500*2000*1200

|

500*500

|

250-360

|

4.0-6.5

|

37*2

|

|

400

|

4000

|

3000*2000*1200

|

500*600

|

250-380

|

6.8-8.0

|

45*2

|

Inner package:

Plastic packing

Outer package: Wooden case

Delivery : Within 20 days after the order

Henan Mingxin Machinery Co., Ltd is a company that integrates science, industry and trade. The company mainly sells mechanical equipment and accessories, pipeline equipment, refractory materials, abrasive materials, water purification equipment, wire and cable. Our company follows the human-oriented, honest, pioneering entrepreneurial spirit with scientific and technological innovation. We have always regarded the technology as the motive force, the market as the orientation to make the products first-class.

Pre-Sales:

Act as a good adviser and assistant of clients, enable them to get rich and competitive from the returns of their investment.

1. Select suitable equipment model.

2. Design and manufacture products according to clients special requirements.

3. Train technical personnel for clients.

Respect clients, devote ourselves to improving the total value of clients.

1. Take photos (including raw material,semi-products, final products and loading products).

2. Pre-check and accept products ahead of delivery.

Provide considerate service to minimize clients worries.

1. Provide civil engineering drawings of the equipment.

2. Free training(including installation, maintaince) to every customer.

3. Install and debug the equipment, ensure the dryer running smoothly.