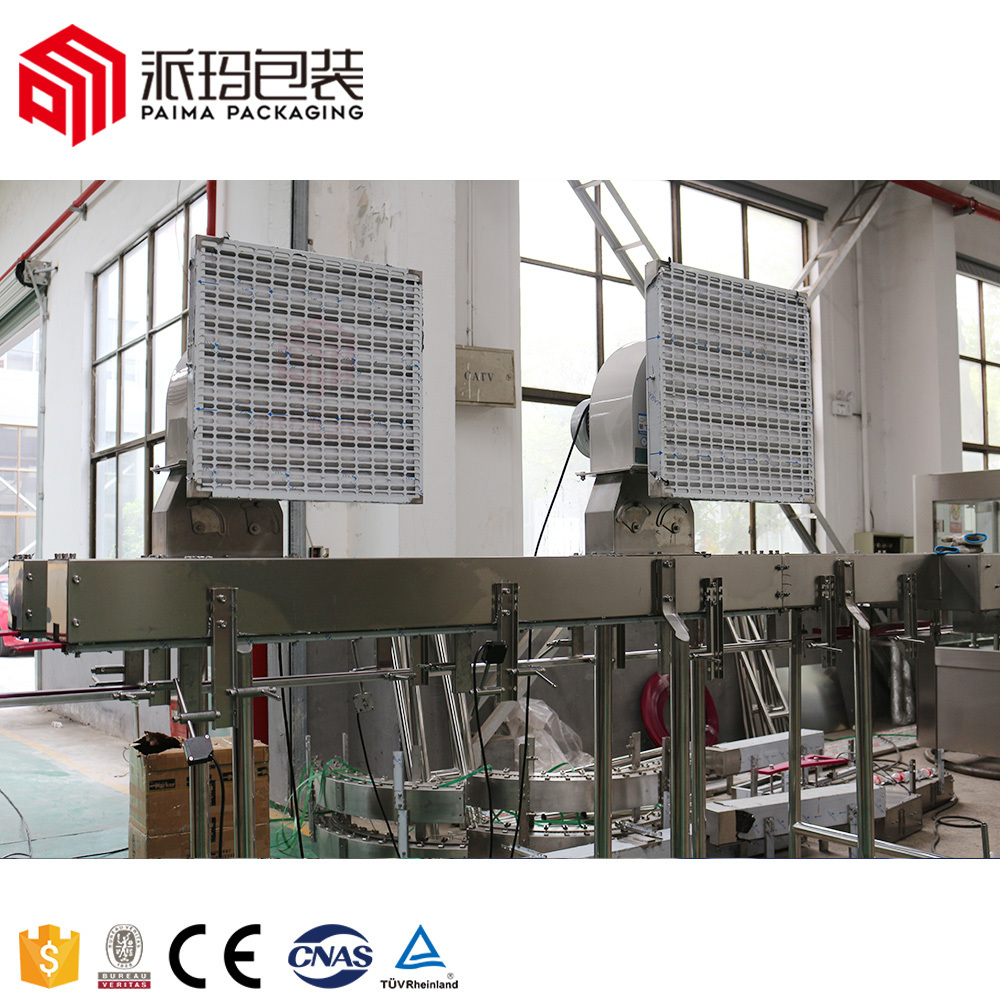

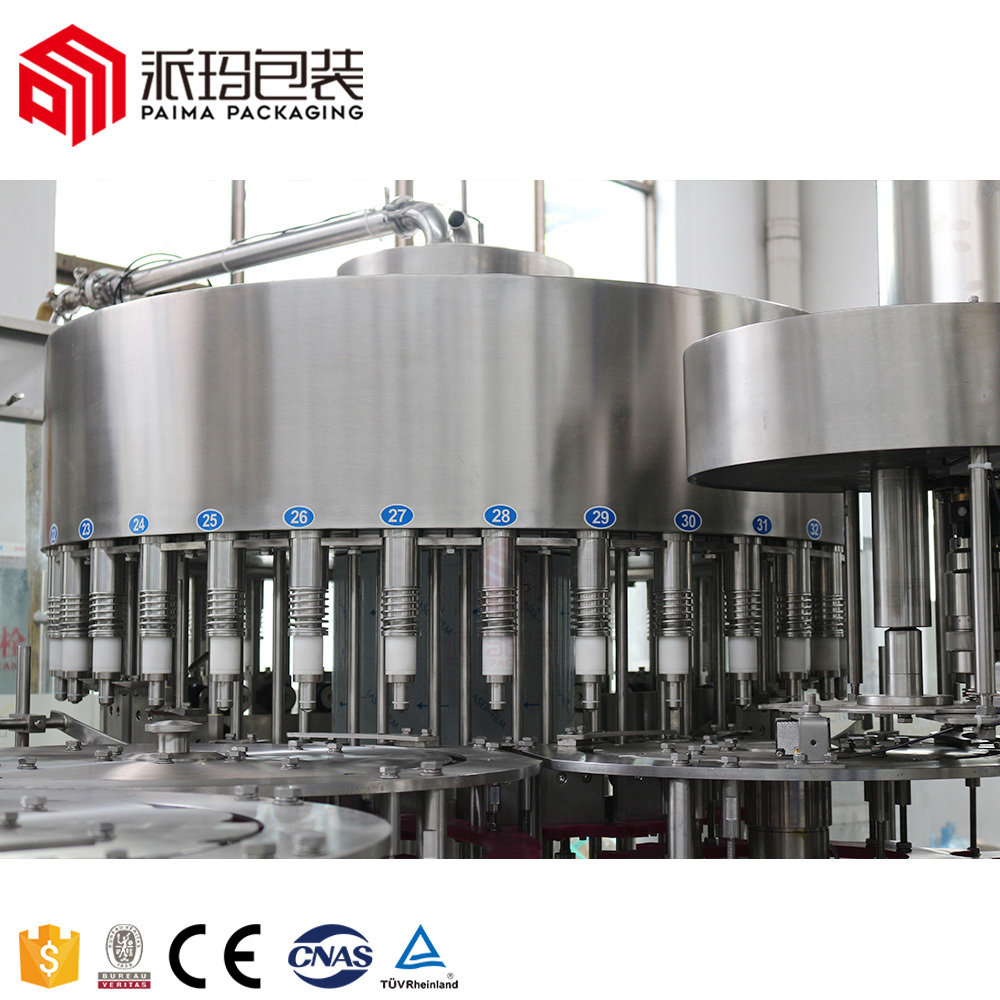

3-in-1 filling monoblock, combined with rinsing, filling and capping. It is innovated and designed in the requirement of still pure water and mineral water, on the bases of introducing, digesting and absorbing advanced technology from Germany and Italy.

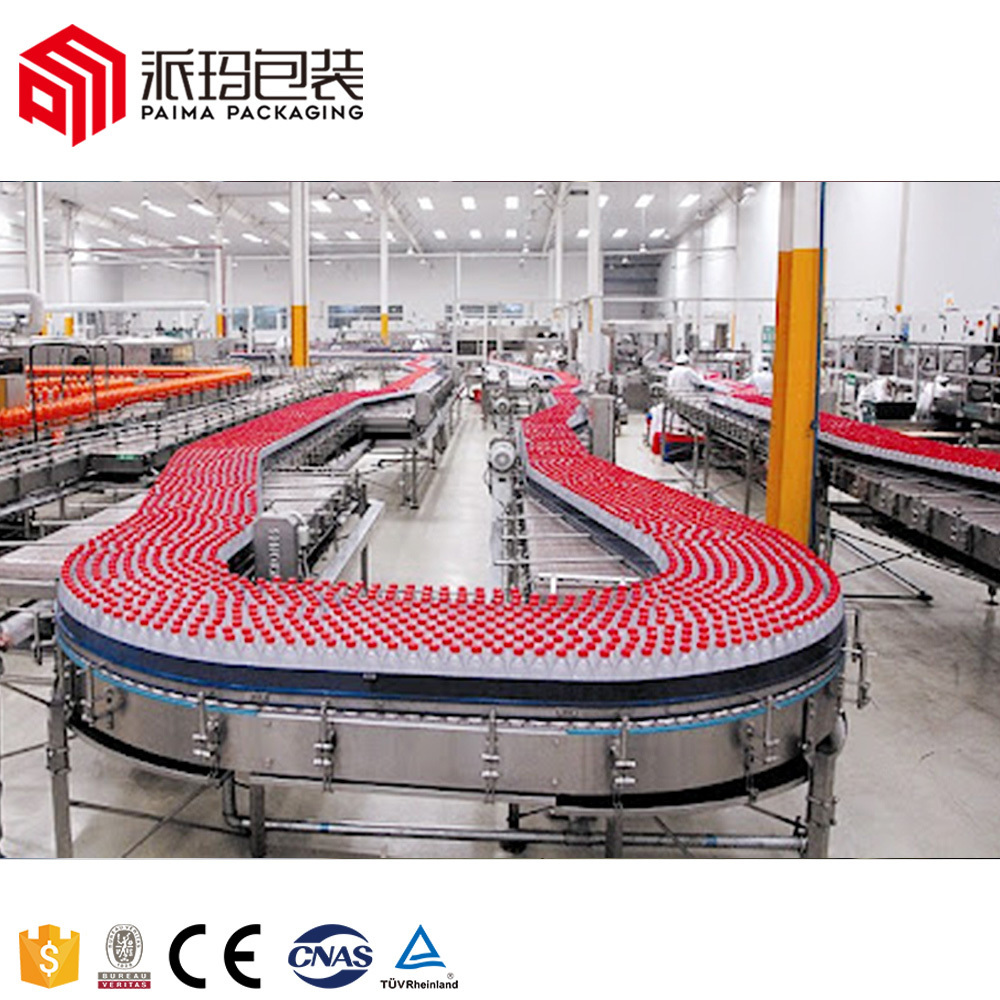

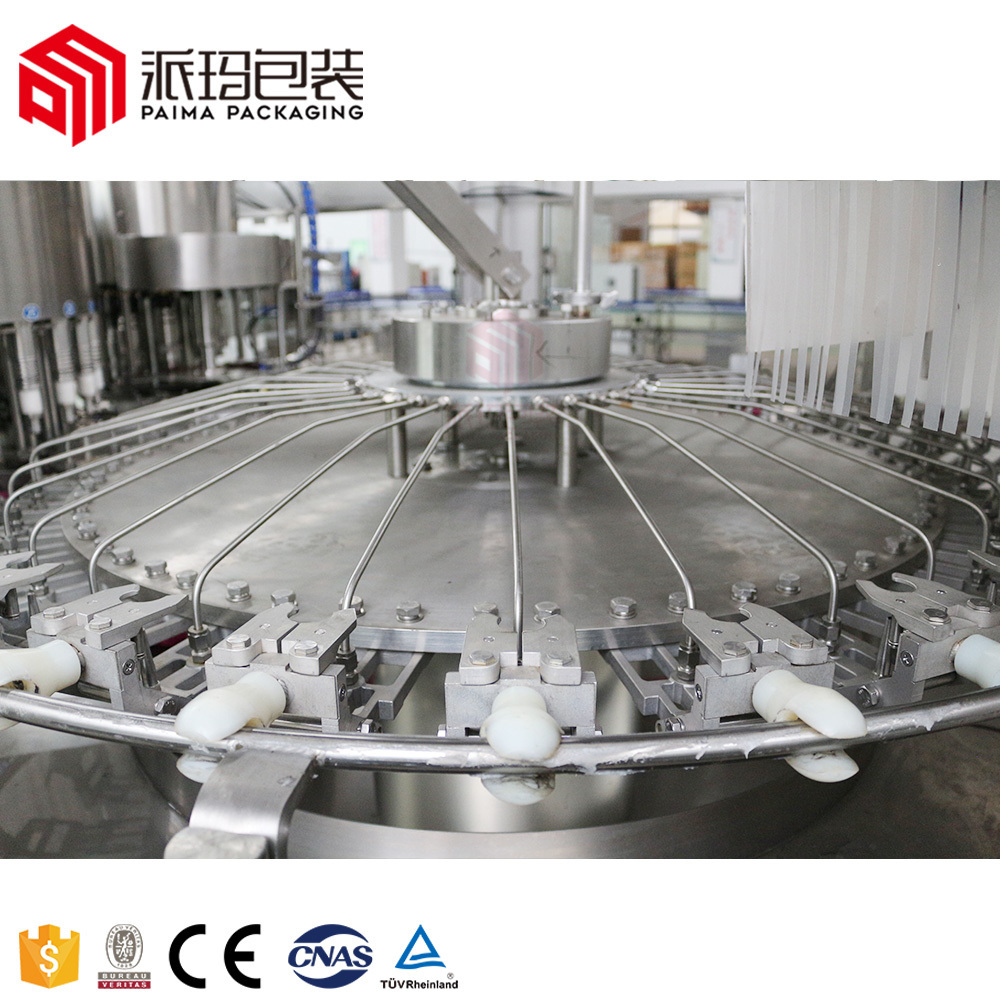

The water filling machine is mainly used in the beverage filling operations. The three functions of bottle wash, fill and seal are composed in one body of the machine. The whole process is automatic. The machine is used in filling juices, mineral water and purified water in bottles made of polyester and plastics. The machine can also be used in hot filling if being installed with temperature controlling device. The handle of the machine can be freely and conveniently turned to adjust the machine to fill various types of bottles. The filling operation is faster and more stable because the micro pressure filling operation of the new type is adopted.

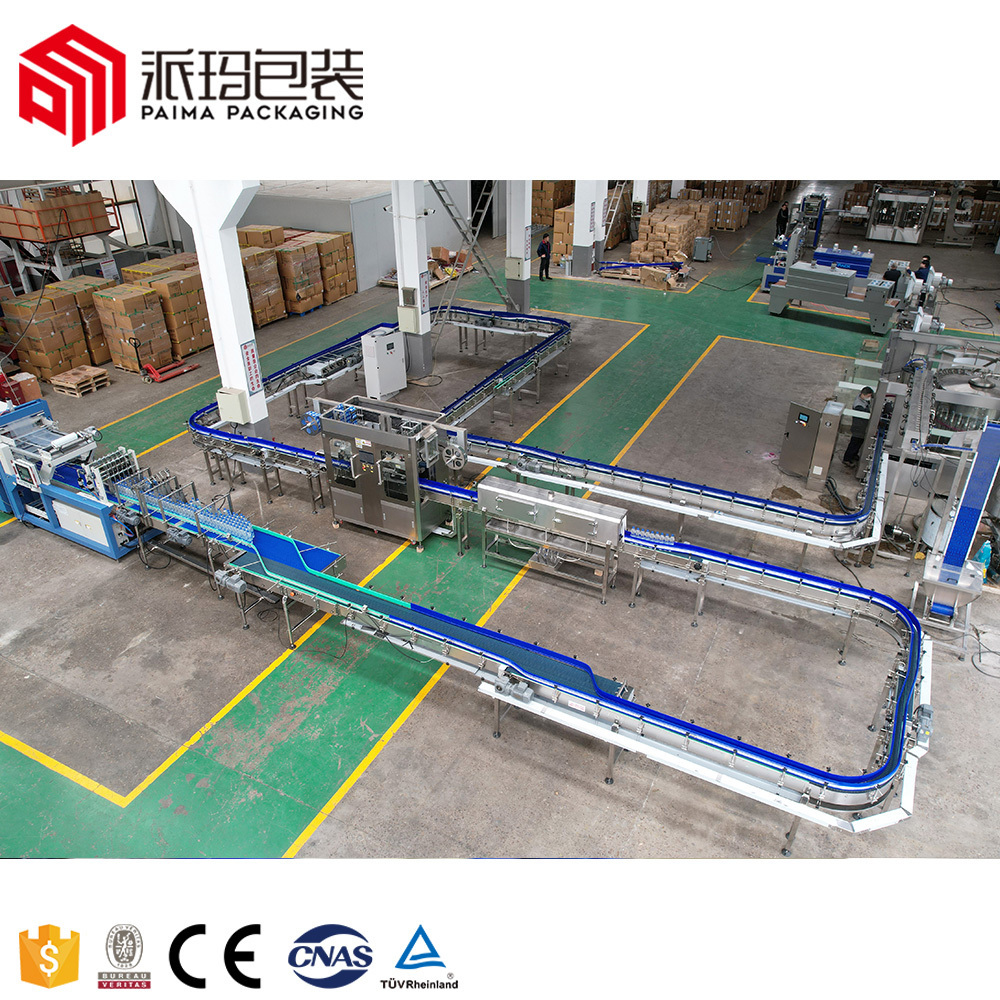

Beverage Machinery can finish all the process such as press bottle, filling and sealing, it can reduce the materials and outsiders touch time, improve the sanitary conditions, production capacity and economic efficiency.