This US customer Tom Smith,their company is our first US customer who making tripod products.

We made a set of tripod for them and here is there comments:

Hello Ella,

I got the cases and I am very proud. I wouldn't change a thing! You guys did a wonderful job and please relay that to Zetar team. I will be letting you know here shortly the dimensions of the next case. It is great having a business relationship with you guys. I hope you and your family are doing well and that the weather is beautiful.

Tom

- Product Details

- {{item.text}}

Quick Details

-

Colors Available:

-

Pantone/RAL and other custom colors

-

Material Experience:

-

ABS/Acetal/Acrylic/CPVC/ Nylon/Polycarbonate/Polyester/PolythyleneABS

-

Certifications:

-

ISO9001/TS16949/QS/ISO14001

-

Surface Finish:

-

Texture/Sandy/MT/YS/SPI/EDM finish/smooth/glossy

-

Drawing Format:

-

STEP/STP/IGS/X-T/STL/CAD/PDF/DWG and Other

-

Biggest Part Size:

-

1500*1500mm*1000mm

-

Biggest Part Weight:

-

5800g/13 Pound

-

Mold Life:

-

500000 shots

-

Lauguage:

-

English/Japenese/Spainish/French/Chinese

-

Tolerance:

-

0.02mm -0.05mm

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

ZETAR

-

Model Number:

-

ZETAR

-

Colors Available:

-

Pantone/RAL and other custom colors

-

Material Experience:

-

ABS/Acetal/Acrylic/CPVC/ Nylon/Polycarbonate/Polyester/PolythyleneABS

-

Certifications:

-

ISO9001/TS16949/QS/ISO14001

-

Surface Finish:

-

Texture/Sandy/MT/YS/SPI/EDM finish/smooth/glossy

-

Drawing Format:

-

STEP/STP/IGS/X-T/STL/CAD/PDF/DWG and Other

-

Biggest Part Size:

-

1500*1500mm*1000mm

-

Biggest Part Weight:

-

5800g/13 Pound

-

Mold Life:

-

500000 shots

-

Lauguage:

-

English/Japenese/Spainish/French/Chinese

-

Tolerance:

-

0.02mm -0.05mm

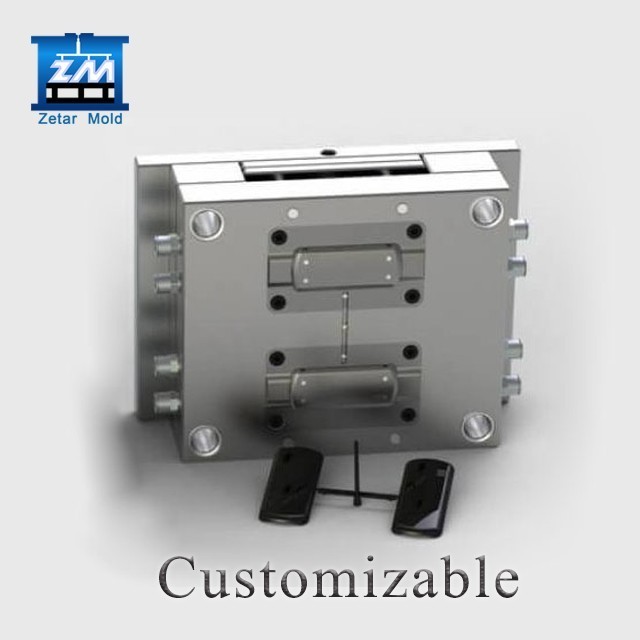

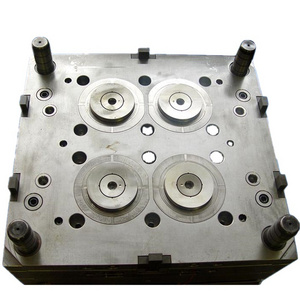

Shock resistance Tough Plastic Part Moulding Zetar

1-Zetar provide high quality custom plastic injection molded parts

2-Injection molded parts can be different material such as ABS/PC/PP/HDPE/POM/PA6/PA6+GF/PVC/NYLON/PMMA/PET Ect

3-Zetar can also provide different surface treatment for injection molded parts

4-Commonly use surface treatment for injection molded parts as:Texture/Sandy/MT/YS/SPI/EDM finish/smooth/glossy/VDI

5-Beside making injection molded parts,we also provide printing,welding,assembly and packing service

|

Product Description

|

ODM plastic injection molding

|

|

Plastic Materials:

|

PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,...etc.

|

|

Standard:

|

ISO9001:2008

|

|

Other materials:

|

Rubber, Slilconce rubber, LSR,Aluminum, Zinc,Copper...Metal...etc.

|

|

Quality:

|

RoSH and SGS standard

|

|

Feature:

|

Non marking and Non flash

|

|

Size:

|

According to your 2D, 3D Drawing

|

|

Color,Quantity,Unit price,Tooling cost,Tooling size:

|

To be discussed

|

|

Package:

|

Standard exported Wooden box packed, Fumigation process(upon required)

|

|

Mold Building Lead Time:

|

T1, 4-5 weeks, Part measurement report (upon required).

|

|

Export Country:

|

Europe, Japan, America, Australian, UK, Canada, France, Germany, Italy...etc.:

|

|

Experience:

|

13 years experience in plastic injection mold making and plastic prouducts produce.

|

|

To be discussed

|

In-Mold Decoration, Injection Mould, Plastic Mold, Overmould, 2K Mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold,Collapsible Core Mold, Die Sets, Compression Mold, Cold Runner System LSR Mold,...etc.

|

|

Mould Base:

|

Hasco Standard, European Standard, World Standard

|

|

Mould Base Material:

|

LKM, FUTA, HASCO, DME,...etc. Or as per Customer's Requirment.

|

|

Surface Finish:

|

Texture(MT standard), High gloss polishing

|

|

Cavity/Core Steel:

|

P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 ...etc.

|

|

Hot/ Cold Runner

|

HUSKY, INCOE, YDDO, HASCO, DME, Masterflow, Mastip, Taiwan made brand...etc.

|

|

Mould Life:

|

5,000 to 1,000,000 Shots. (According to your working environment.)

|

|

Design & Program Softwares:

|

CAD, CAM, CAE, Pro-E, UG, Soild works, Moldflow, CATIA....etc.

|

|

Equipments:

|

High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000T available.

|

Top Quality Plastic Injection Molding Manufacturer

49% buyers found Plastic Products also liked Top Quality Plastic Injection Molding Manufacturer

China OEM low price custom plastic parts injection molding manufacturer

30% Buyers who searched injection molding bought China OEM low price custom plastic parts injection molding manufacturer

Zetar Industry Co.,Limited Shanghai China

Our company has In-house tooling shop- fully equipped 6000 square feet tool room,making sure your molds making in house,providing free mold routine maintenance,and also mold repair work if you need.

Meanwhile 90 ton - 1100 ton injection molding machines 20 sets,30000 square feet injection molding room including 250 square feet M7 class clean room.We can produce parts from 0.01pound to 13 pounds.

Mold Shop

Tom from US like Zetar

Thomas from NL speak highly of Zetar

Thomas Kuijper from Netherland working in battery industry,we have working with them since 2013 for their battery housings.

Hello Tina,

Cargo arrived.I am happy for all these smooth work.Your team is growing so fast and i like their communication.I believe we soon will have more works for Zetar. I hope you and your family are doing well

Thomas

Chirs from Canada prefer to work with Zetar

Chris from Canada come to visit us in 2017,bring his two molds made in Shenzhen to us for mass production.They under big pressure from kickstater backers,while the factory made molds for them can't do production and molds molding delayed a lot already.

Working with us,Chirs get big success with his kickstarter campaign,and now they are making new version and we already involved in new product design.

1. Are you a trading company or a manufacturer?

We are a manufacturer as you can see our workshop as above.

2. What kind of trade terms can you do?

EX-WORKS,FOB,CIF,DDP DDU

3. What is your terms of payment?

50% Mold cost deposit,balance mold cost +50% production cost paid when samples confimed,Balance production cost paid against copy of B/L. We accept T/T

4. Do you support OEM ?

Yes, we can produce by technical drawings or samples.

5. How about your delivery time?

Generally, it take 40 days ( 30 days do mold and 10 days do mass production).