It used for making wooden round rod from square sticks.And operating range from 15-50mm.

- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

12.1

-

Key words:

-

automatic wooden stick Wood Round Rod Making Machine

-

Min.length:

-

300mm

-

Max.length:

-

5000mm

-

Rotary cutting excess stock material:

-

1pcs

-

Raw material for plate:

-

1-6

-

Processing diameter range:

-

4-38mm

-

Feed motor power:

-

1.1kw

-

Feed speed:

-

6-30m/min

-

Max.tool diameter:

-

100mm

-

Tool spindle speed:

-

8500r/min

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

NEWEEK

-

Weight (KG):

-

500 KG

-

Power (kW):

-

12.1

-

Key words:

-

automatic wooden stick Wood Round Rod Making Machine

-

Min.length:

-

300mm

-

Max.length:

-

5000mm

-

Rotary cutting excess stock material:

-

1pcs

-

Raw material for plate:

-

1-6

-

Processing diameter range:

-

4-38mm

-

Feed motor power:

-

1.1kw

-

Feed speed:

-

6-30m/min

-

Max.tool diameter:

-

100mm

-

Tool spindle speed:

-

8500r/min

Products Description

NEWEEK CE round wood rod Automatic making mop rod wood dowel making machine for sale

Commercial Broom Stick Milling Machine.

Technical Parameter

|

model

|

MB9010T

|

|

Min.length

|

300mm

|

|

Max.length

|

5000mm

|

|

Rotary cutting excess stock material

|

1pcs

|

|

Raw material for plate

|

1-6

|

|

Processing diameter range

|

4-38mm

|

|

Feed motor power

|

1.1kw

|

|

Feed speed

|

6-30m/min

|

|

Uper knife axis motor power

|

5.5kw

|

|

Down knife axis motor power

|

5.5kw

|

|

Max.tool diameter

|

100mm

|

|

Tool spindle speed

|

8500r/min

|

|

Extraction outlet size

|

150mm

|

|

Spindle diameter

|

30mm

|

|

Total power

|

12.1kw

|

|

Size

|

1200*800*1300mm

|

Details Images

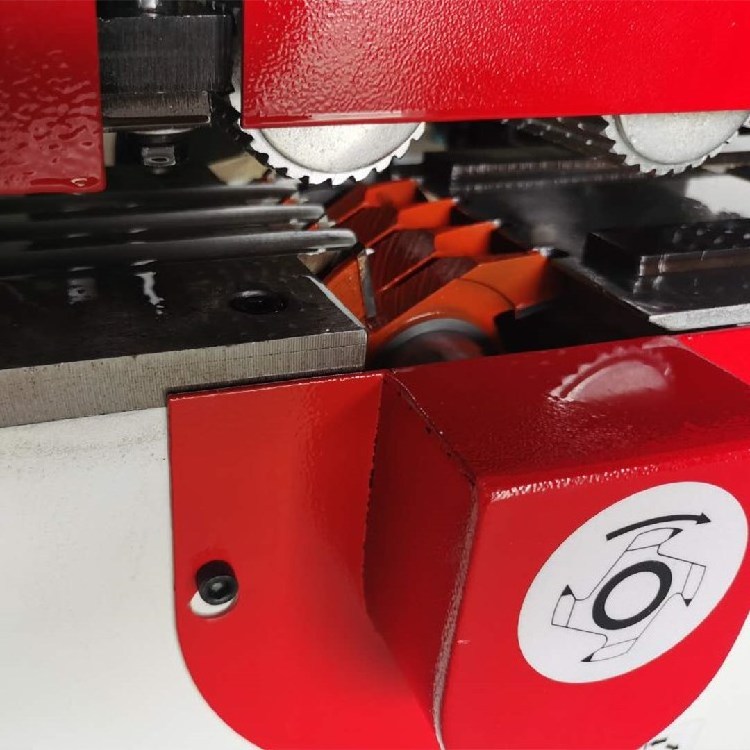

1. Multi-specification cutters, different size cutters produce different size round bars, the cutter size is up to you, and only one set of cutters is provided at the factory.

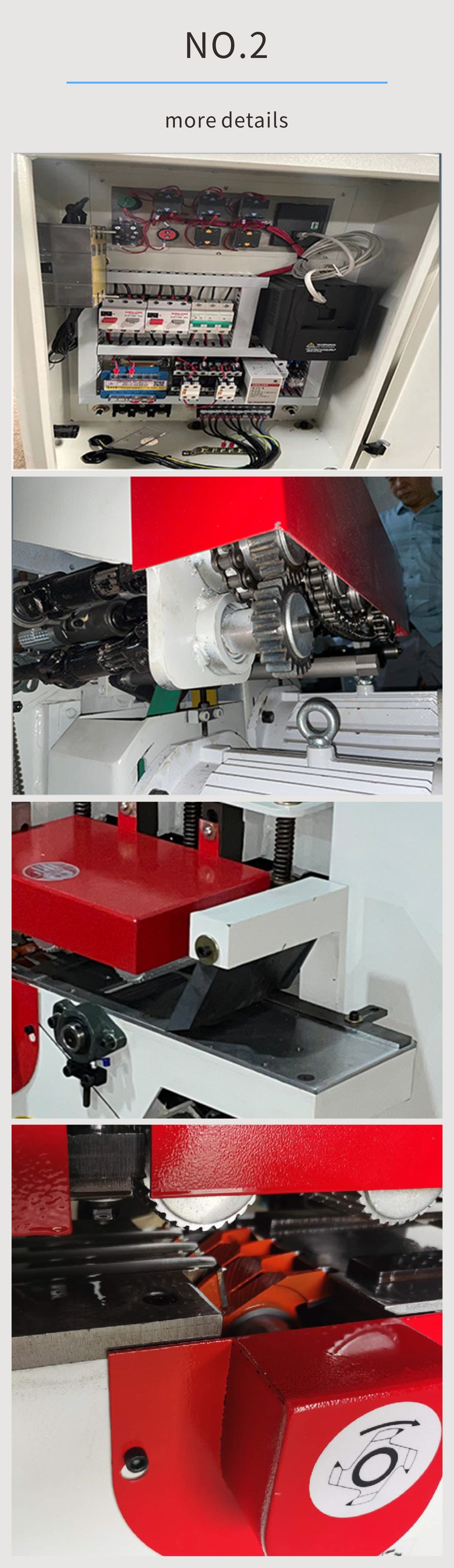

2. High-power motor, 5.5kw each for dual spindles, 1.1kw reduction motor, and 12.1kw total power.

3. The control panel, multiple buttons, simple operation, ergonomic design, restore simple woodworking production.

4. The gear chain and the gear chain are driven synchronously, the running force is even and stable, and the driving is smooth and smooth

5. Automatic feeding wheel, no need to manually push the material, assist automatic processing, the diameter of the feeding wheel is 60mm, the inner hole is 25mm

6. Anti-rebound device, tilt the card, keep the raw material from going backwards,operate safely, and protect the personal safety of employees

7. Reasonable wiring, professional electrician wiring, in line with safe circuit standards, no worries about burning out the circuit

Packing&Delivery

Packing:

Usually, we use standard export wooden cases for packing this machine. We will first wrap the entire machine with a plastic film to prevent the machine from being damaged and scratched. Then fix the fuselage with a wooden box to prevent the machine from being bumped and damaged during transportation. If you have special requirements, you can contact us.

Delivery

About this machine, we have two ways to transport by sea and air. Please provide us with

your address so that we can choose a more suitable transportation method for you. We can also deliver the machine to your agent in

China if you have.

your address so that we can choose a more suitable transportation method for you. We can also deliver the machine to your agent in

China if you have.

Certifications

We have been engaged in the wood machinery industry for many years and have accumulated rich experience. We always insist on producing machines with rigorous and scientific attitude, and at the same time strengthen personnel training and provide customers with quality services more professionally.

About us

1. We have one-on-one exclusive customer service staff, 24 hours online. In order to better understand the hydraulic bending machine, you have any questions, please feel free to contact us, we will provide you with professional answers.

2. This machine's warranty period of our manual sheet hydraulic bending machine is 1 year. During the warranty period, the machine parts are damaged by non-human factors, we will provide new parts for replacement free of charge (except the wearing parts).

3. In the same competitive conditions, we sincerely offer you the most favorable price without reducing product performance or replacing parts.

4. We provide product customization services. As for the CNC PLC 60 ton 100 ton hydraulic bending machine, if you have special requirements, we can make it according to your requirements.

Thank you for your precious time! For more information about hydraulic bending machine, please feel free to contact me!

2. This machine's warranty period of our manual sheet hydraulic bending machine is 1 year. During the warranty period, the machine parts are damaged by non-human factors, we will provide new parts for replacement free of charge (except the wearing parts).

3. In the same competitive conditions, we sincerely offer you the most favorable price without reducing product performance or replacing parts.

4. We provide product customization services. As for the CNC PLC 60 ton 100 ton hydraulic bending machine, if you have special requirements, we can make it according to your requirements.

Thank you for your precious time! For more information about hydraulic bending machine, please feel free to contact me!

Hot Searches