- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

Hot Sale Product

-

Weight (KG):

-

50000 KG

-

Power (kW):

-

80

-

Product name:

-

compressed wood pallet making machine

-

Type:

-

Hot Press Machine for wood pallet making

-

Layers:

-

one

-

Nominal pressure:

-

2000ton

-

Quantity of cylinders:

-

2

-

Size of work size:

-

1500*1300 or customized

-

Main electrical components:

-

Schneider

-

Electrical appliances:

-

PLC Shneider and Delta plc

-

Control methods:

-

Full automatic

-

Cylinder:

-

Wuxi cylinder

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BKS

-

Machine Type:

-

wood pallet making machine

-

Marketing Type:

-

Hot Sale Product

-

Weight (KG):

-

50000 KG

-

Power (kW):

-

80

-

Product name:

-

compressed wood pallet making machine

-

Type:

-

Hot Press Machine for wood pallet making

-

Layers:

-

one

-

Nominal pressure:

-

2000ton

-

Quantity of cylinders:

-

2

-

Size of work size:

-

1500*1300 or customized

-

Main electrical components:

-

Schneider

-

Electrical appliances:

-

PLC Shneider and Delta plc

-

Control methods:

-

Full automatic

-

Cylinder:

-

Wuxi cylinder

Product Description

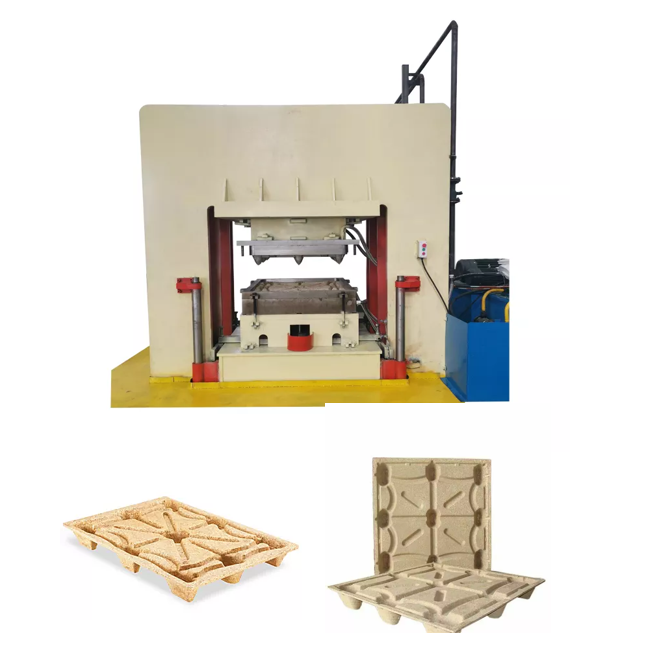

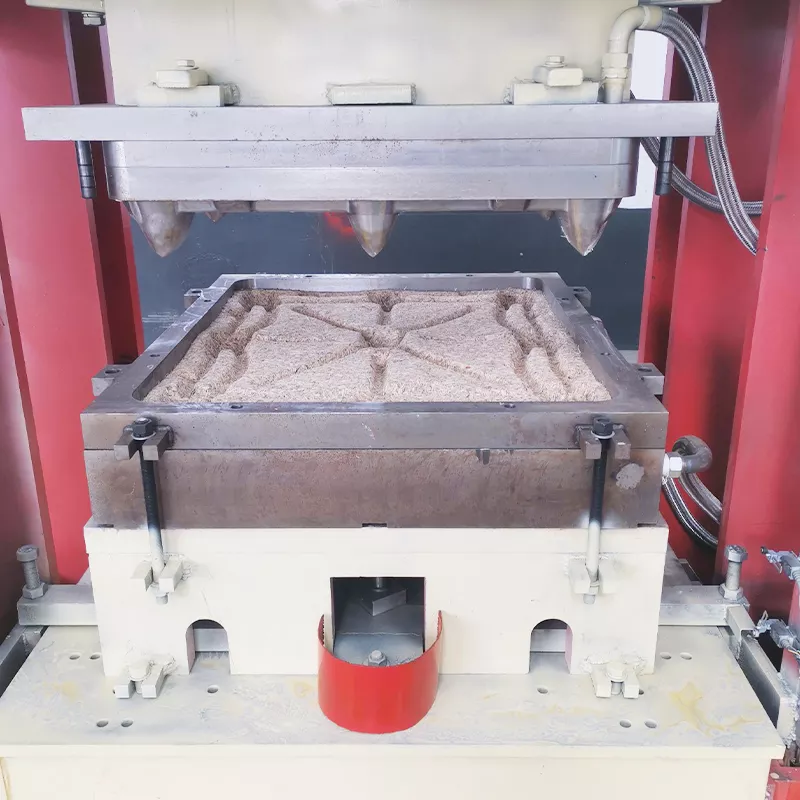

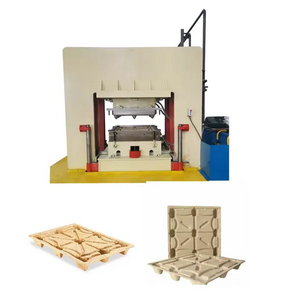

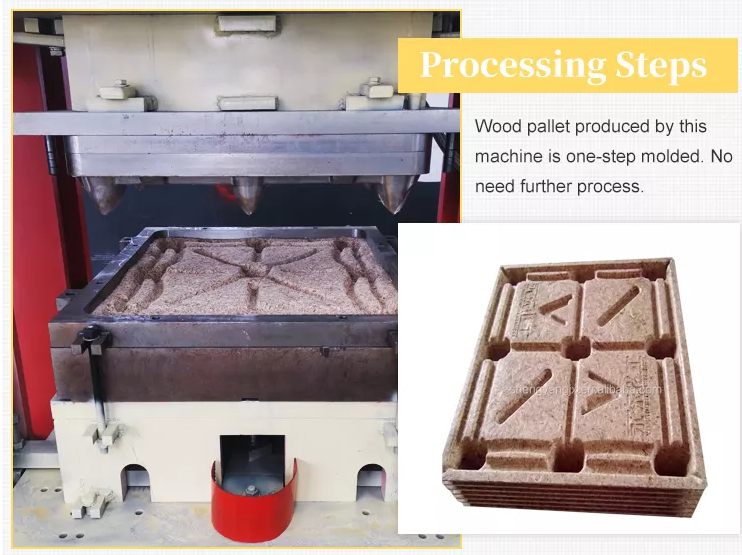

Compressed wood pallet making machine sawdust pallet making machine

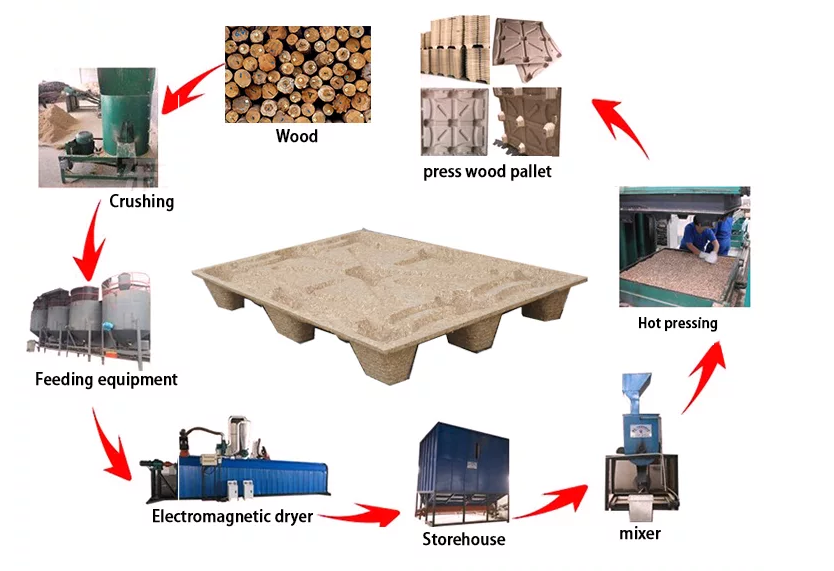

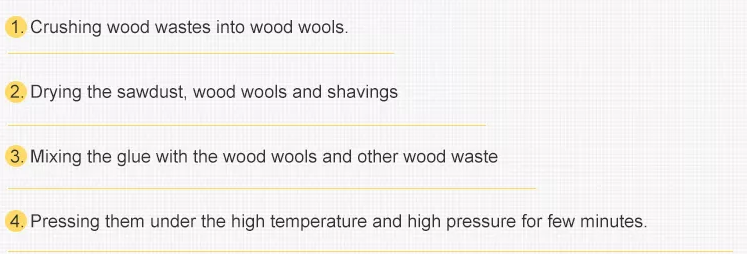

Mould pressing tray is made of wood sawdust, wood chips and other plant fibers through drying, sizing, high temperature and high pressure. It has the characteristics of high load bearing, no deformation, moisture-proof, fire-proof and insect-proof, no fumigation for export and no pollution for environmental protection and so on. It is suitable for food, chemical industry, machinery, hardware, electric appliance, building materials and many other industries.

The operation process of this project is very simple. Simply plugged into a power supply for steam or heat conduction oil, can organize production, each hot pressing time is 8 minutes, (by adjusting device of the equipment installation, can be adjusted according to the production specifications). Each press machine can produce about 140 pieces per day, and only 2 workers can operate 3 presses in a single shift. For crushing and drying, need 2 person to operate. Steam consumption is 0.05 tons per hour for each press machine and 0.5 tons per hour for dryer.

The operation process of this project is very simple. Simply plugged into a power supply for steam or heat conduction oil, can organize production, each hot pressing time is 8 minutes, (by adjusting device of the equipment installation, can be adjusted according to the production specifications). Each press machine can produce about 140 pieces per day, and only 2 workers can operate 3 presses in a single shift. For crushing and drying, need 2 person to operate. Steam consumption is 0.05 tons per hour for each press machine and 0.5 tons per hour for dryer.

Specification

Main Data of Wood Pallet Hot Press

|

No

|

Item

|

Data

|

|

1

|

Nominal pressure

|

1500ton

|

|

2

|

Feeding direction

|

transverse

|

|

3

|

Layers

|

1layer

|

|

4

|

Distance between layer(mm)

|

550

|

|

5

|

Quantity of hot platens

|

2

|

|

6

|

Size of hot platen

|

1500*1300mm

|

|

7

|

Quantity of main cylinder

|

1

|

|

8

|

Diameter of main cylinder

|

900

|

|

9

|

Withstand voltage(Mpa)

|

≤25

|

|

10

|

Pallet embryo size(mm)

|

1200*1000/1300*1100/1100*1100

|

|

11

|

Frame methods

|

Gantry steel frame

|

Details Images

Details

Finished Product

Hot Searches