Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Qingdao Tongsan

-

Voltage:

-

3Phase/380V/50Hz or customized

-

Dimension(L*W*H):

-

25m*1.5m*2m

-

Power (kW):

-

55

-

Weight:

-

15 KG

-

Motor brand:

-

Siemens

-

Inverter:

-

ABB

-

Temperature controller:

-

Omron

-

Application 1:

-

Decking/fence/post/wall panel

-

Application 2:

-

window and door frame

-

Application 3:

-

door board

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

22:1

-

Screw Speed (rpm):

-

20 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Qingdao Tongsan

-

Voltage:

-

3Phase/380V/50Hz or customized

-

Dimension(L*W*H):

-

25m*1.5m*2m

-

Power (kW):

-

55

-

Weight:

-

15 KG

-

Motor brand:

-

Siemens

-

Inverter:

-

ABB

-

Temperature controller:

-

Omron

-

Application 1:

-

Decking/fence/post/wall panel

-

Application 2:

-

window and door frame

-

Application 3:

-

door board

Product Description

Our Qingdao Tongsan Plastic Machinery is specialized for making kinds of PP/PE/PVC WPC wood plastic composite machines for more than 24 years. We developed advaced technology.To offer customer high quality machine and good after-sale service.

Our main products:

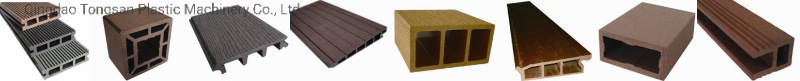

(1)PP/PE WPC wood plastic composite WPC profile making machine for making outdoor WPC decking,fence, post, pallet, flooring, chair,house wal panel etc.

(2)PVC/UPVC WPC wood plastic composite WPC profile making machine for making window and door profile making machine, wall and ceiling panel etc.

(3)PVC/UPVC WPC wood plastic composite WPC door panel making machine for making door panel and door board.

(4)PVC/UPVC WPC wood plastic composite WPC foam board making machine for making celuka foam board.

Our main products:

(1)PP/PE WPC wood plastic composite WPC profile making machine for making outdoor WPC decking,fence, post, pallet, flooring, chair,house wal panel etc.

(2)PVC/UPVC WPC wood plastic composite WPC profile making machine for making window and door profile making machine, wall and ceiling panel etc.

(3)PVC/UPVC WPC wood plastic composite WPC door panel making machine for making door panel and door board.

(4)PVC/UPVC WPC wood plastic composite WPC foam board making machine for making celuka foam board.

Advantage and application for WPC products

The wood plastic composite material(WPC) is a new kind of environment-friendly and 100%recycable material,which uses straws in agricultural production (such as wheat-straw, cotton stalk, rice chaff, wood sawdust) and recycled plastic( such as plastic film bags, plastic bottles) as main raw material. The WPC profiles and plates can be used as package material, industrial pallets,guardrail, pavilion, and decking in city construction, national defense building material, car and ships indoor decorative material, window and doors, ceiling, wall cladding,indoor floor, furniture and cupboard etc.

The wood plastic composite material(WPC) is a new kind of environment-friendly and 100%recycable material,which uses straws in agricultural production (such as wheat-straw, cotton stalk, rice chaff, wood sawdust) and recycled plastic( such as plastic film bags, plastic bottles) as main raw material. The WPC profiles and plates can be used as package material, industrial pallets,guardrail, pavilion, and decking in city construction, national defense building material, car and ships indoor decorative material, window and doors, ceiling, wall cladding,indoor floor, furniture and cupboard etc.

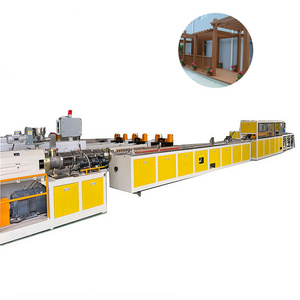

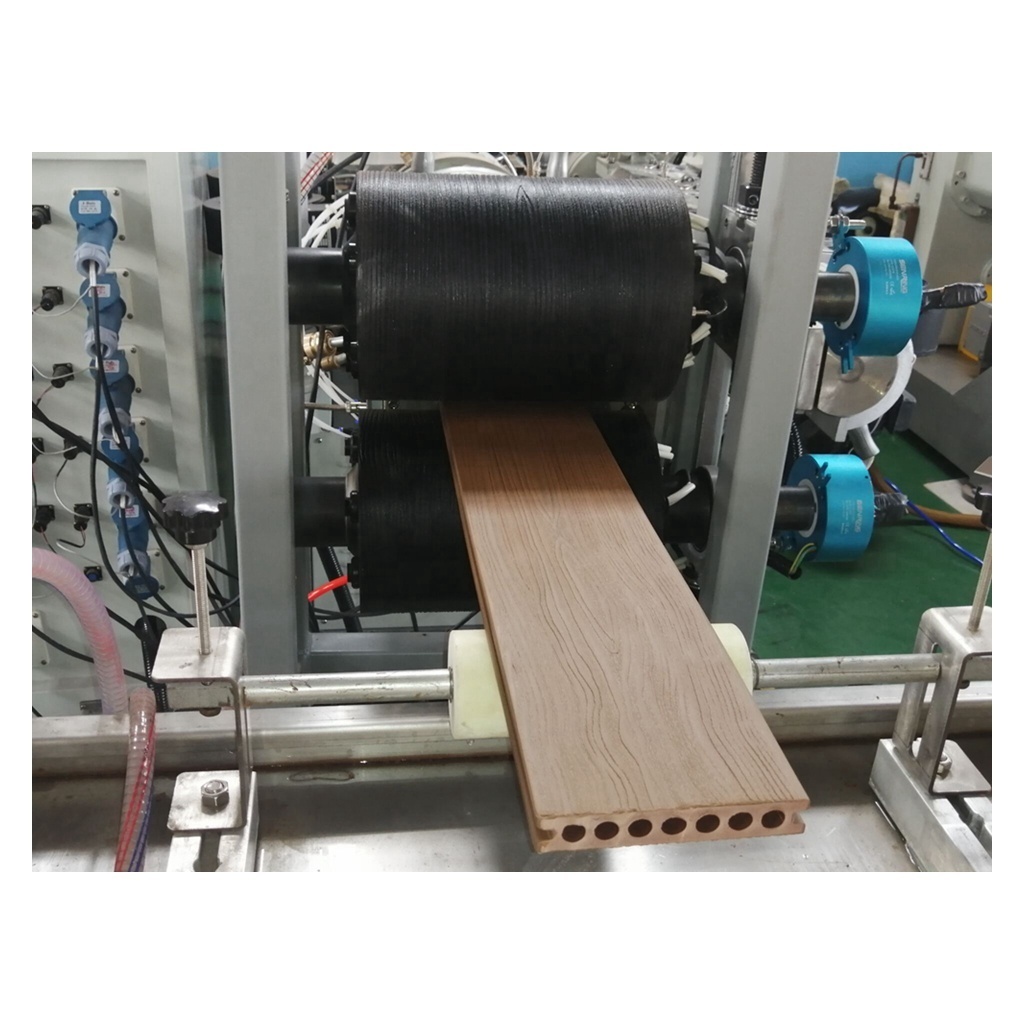

PP/PE WPC wood plastic composite machine

PP/PE WPC profile making machine can continuously produce PP/PE WPC profile. Including PP/PE WPC decking floor, PP/PE WPC outdoor wall panel, PP/PE WPC fence , post and so on.

The customer can also use this line to produce PVC WPC window and door profile by changing the screw and mould.

The customer can also use this line to produce PVC WPC window and door profile by changing the screw and mould.

|

Material

|

Percentage

|

|

Recycled PP/PE plastic material

|

25-30%

|

|

Wood powder made from wood/rice husk/rice straw/wheat straw/wheat husk

|

65-70%

|

|

Chemicals: PE wax, stearic acid, CaCo3, pigments, coupling agent

|

5%

|

Production flow of PP/PE WPC profile:

a. plastic recycling: washing, crushing ,drying the PP/PE plastic wastage into flakes, the flakes shall be used for WPC production directly.

b. wheat straw powder making: crushing, milling and drying the wheat straw into 80-100 mesh powder

c. material mixing: weighting and mixing all material together according to our formula by hot mixing machine

d. WPC granulating: extrusion by parallel double screw extruder and do hot-pelletizing into WPC granules.

e. WPC extrusion: extrusion by conical double screw extruder and molding in required size and shape with water cooling calibrating, online fixed length cutting.

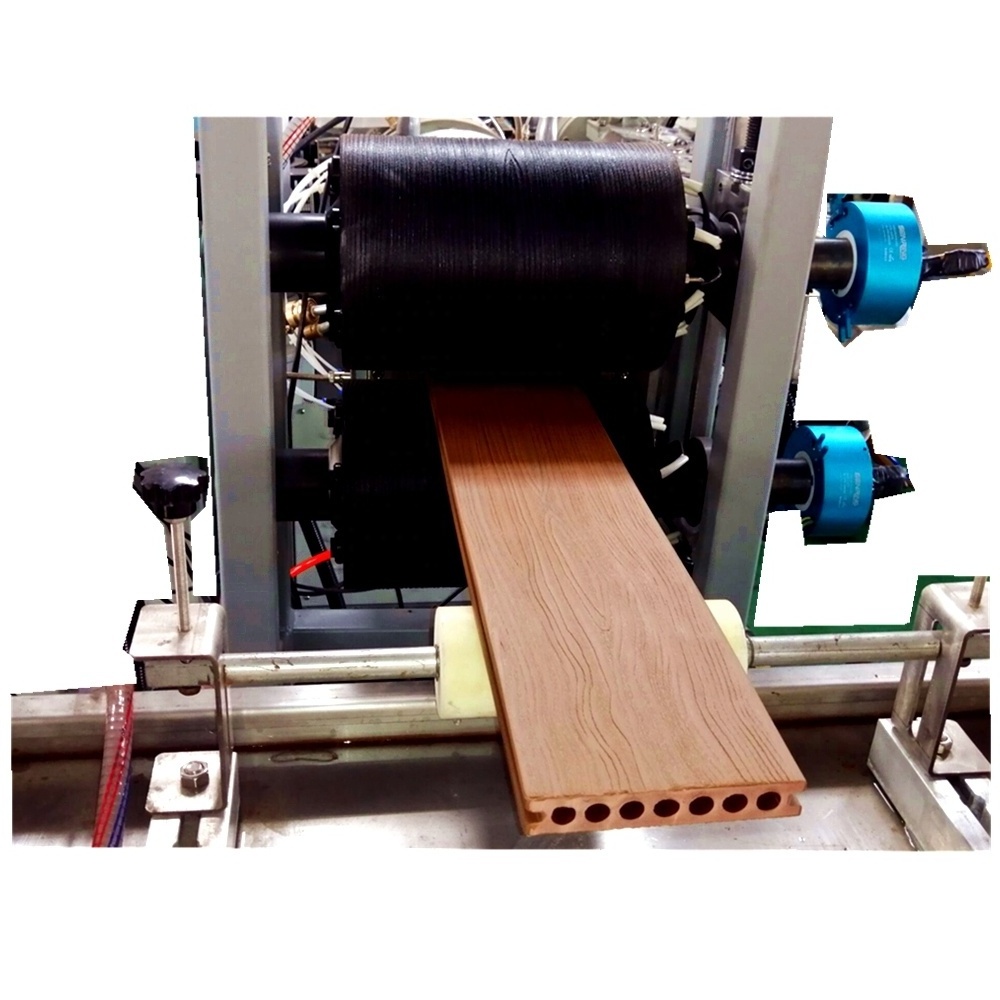

f. WPC surface design: embossing, brushing, or sanding on the surface to make different wooden grain feeling.

a. plastic recycling: washing, crushing ,drying the PP/PE plastic wastage into flakes, the flakes shall be used for WPC production directly.

b. wheat straw powder making: crushing, milling and drying the wheat straw into 80-100 mesh powder

c. material mixing: weighting and mixing all material together according to our formula by hot mixing machine

d. WPC granulating: extrusion by parallel double screw extruder and do hot-pelletizing into WPC granules.

e. WPC extrusion: extrusion by conical double screw extruder and molding in required size and shape with water cooling calibrating, online fixed length cutting.

f. WPC surface design: embossing, brushing, or sanding on the surface to make different wooden grain feeling.

WPC decking machine with online embossing

WPC wall panel making machine(Co-extrusion)

PP PE WPC application

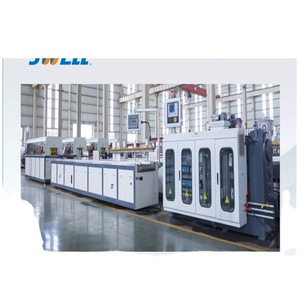

PVC WPC profile machine

This production line continuosly produce PVC WPC profiles, such as door frame and window profile,wall and ceiling panel,skirting etc.

This production line consists of twin conical screw extruder, die head , calibrating table, haul off and cutting machine ,stacker.

This production line consists of twin conical screw extruder, die head , calibrating table, haul off and cutting machine ,stacker.

|

Model

|

SJSZ-51/105

|

SJSZ-65/132

|

SJSZ-80/156

|

|

Max production width

|

200mm

|

250mm

|

600mm

|

|

Extruder capacity

|

100-120kg/h

|

150-180kg/h

|

250-380kg/h

|

|

Main motor power

|

22kw

|

37kw

|

75kw

|

|

Vacuum pump power

|

3kw

|

7.5kw*5.5kw

|

11kw*7.5kw

|

|

Calibrating table length

|

4000mm

|

6000mm

|

6000mm

|

PVC WPC door frame making machine

PVC+ASA co-extrusion window profile machine

PVC WPC door machine

This WPC PVC door making machine line is used for making WPC door panels from PVC and wood powder, the WPC hollow panel can be used either inner and outer door panel, partition, windowsill etc.it centralizes the characters of both plastic and wood, and also

overcomes the shortage of wood, such as water -proof, corrosion resisting, anti-moth, anti-aging, static-free, and flame retarded.

|

Model

|

HG-800

|

HG-1000

|

HG-1200

|

|

Extruder model

|

80/156

|

80/156

|

92/188

|

|

Max width

|

800mm

|

1000mm

|

1200mm

|

|

Max extruder capacity

|

350-380kg/h

|

500-550kg/h

|

500-550kg/h

|

|

Main motor power

|

75kw

|

110kw

|

110kw

|

|

Door thickness

|

20-50mm

|

20-50mm

|

20-50mm

|

We offer turnkey project of PVC WPC door panel project

Hot Searches