- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

U Tech

-

Year:

-

2020

-

Voltage:

-

540V/50Hz

-

Dimension(L*W*H):

-

7.8x3.6x5.4m

-

Hollow part volume:

-

200~250L

-

Screw L/D Ratio:

-

30

-

Screw diameter (mm):

-

120 mm

-

Screw Heating Power(kW):

-

40 kW

-

Extruder Motor Power(kW):

-

90 kW

-

Mold Platen Size(Width)(mm):

-

1420 mm

-

Mold Platen Size(Height)(mm):

-

1600 mm

-

Air Pressure(MPa):

-

1.4 MPa

-

Air Comsumption(m³/min):

-

2.8 m³/min

-

Die Head Heating Power(kW):

-

32 kW

-

Accumulator Capacity(L):

-

25 L

-

Power (kW):

-

112

-

Weight (T):

-

38

-

Model Number:

-

BST-120

-

Blow Moulding Type:

-

160L 200 Litre Drum Extrusion Blow Molding machine

-

Material application:

-

PP PE PVC ABS EVA

-

After sales:

-

2 years

-

PLC:

-

JAPAN MITSUBISH

-

Cavity:

-

Single

-

Color:

-

Customer Choice

-

Max Size of Mold:

-

1300x1800mm

-

Parison Control:

-

MOOG 100 Point

-

Mold material:

-

Aluminium 6061/7075,P20,etc

Quick Details

-

Clamping Force (kN):

-

1200

-

Output (kg/h):

-

350 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

U Tech

-

Year:

-

2020

-

Voltage:

-

540V/50Hz

-

Dimension(L*W*H):

-

7.8x3.6x5.4m

-

Hollow part volume:

-

200~250L

-

Screw L/D Ratio:

-

30

-

Screw diameter (mm):

-

120 mm

-

Screw Heating Power(kW):

-

40 kW

-

Extruder Motor Power(kW):

-

90 kW

-

Mold Platen Size(Width)(mm):

-

1420 mm

-

Mold Platen Size(Height)(mm):

-

1600 mm

-

Air Pressure(MPa):

-

1.4 MPa

-

Air Comsumption(m³/min):

-

2.8 m³/min

-

Die Head Heating Power(kW):

-

32 kW

-

Accumulator Capacity(L):

-

25 L

-

Power (kW):

-

112

-

Weight (T):

-

38

-

Model Number:

-

BST-120

-

Blow Moulding Type:

-

160L 200 Litre Drum Extrusion Blow Molding machine

-

Material application:

-

PP PE PVC ABS EVA

-

After sales:

-

2 years

-

PLC:

-

JAPAN MITSUBISH

-

Cavity:

-

Single

-

Color:

-

Customer Choice

-

Max Size of Mold:

-

1300x1800mm

-

Parison Control:

-

MOOG 100 Point

-

Mold material:

-

Aluminium 6061/7075,P20,etc

Product Description

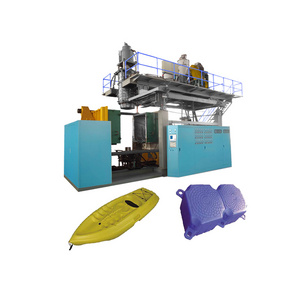

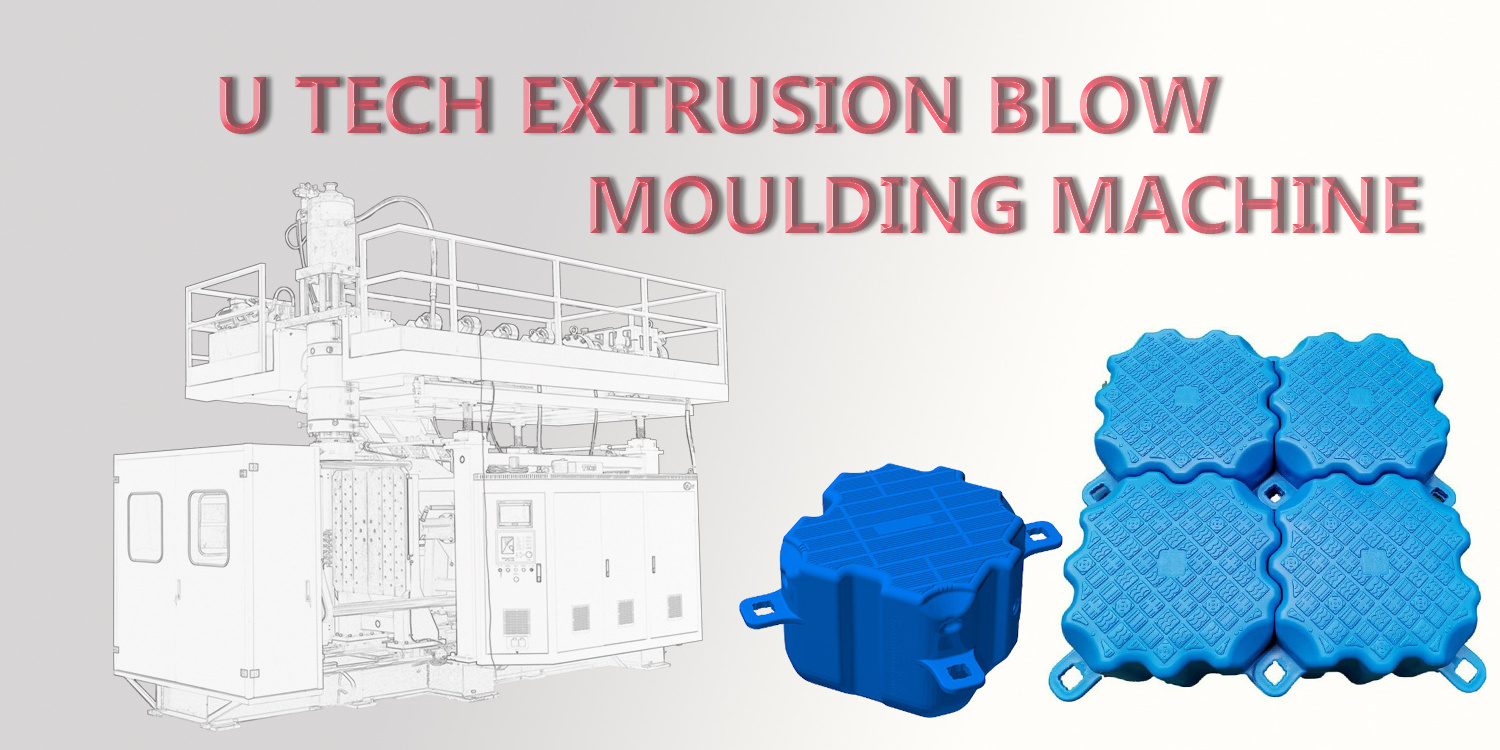

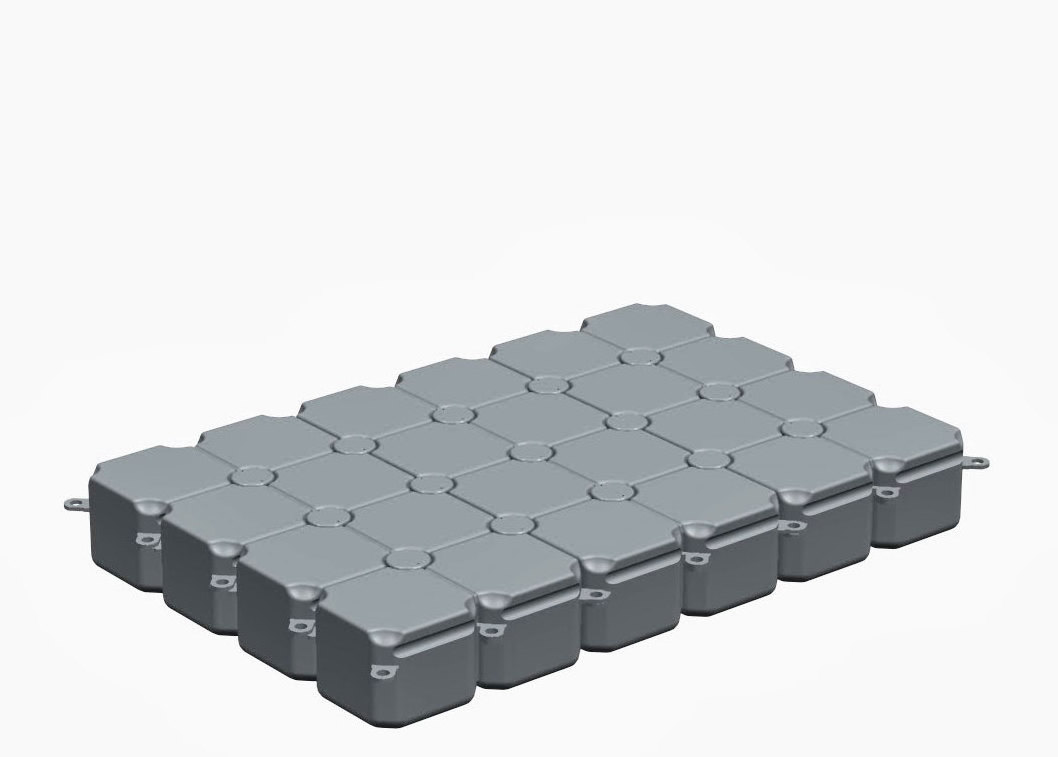

U Tech BST-120 Extrusion blow molding machine is used to produce the 200L, 250L double L-ring drum with multi-layers, such like chemical drum, plastic pallet and oil fuel tank, the machine with servo drive and high efficient HDPE extrusion output, quick and safe operation, easy for trouble shooting, maintenance and other benefit. By changing molds, can realize the production of all kind of plastic tank and drum.

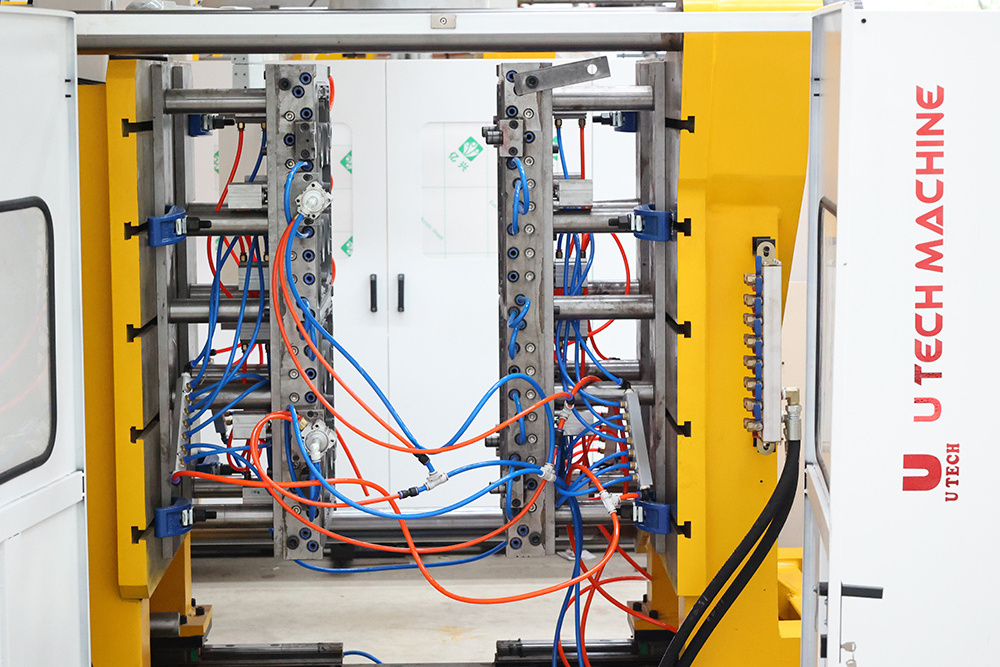

Detailed Images

Technical Parameter

|

Model

|

Unit

|

BST-120

|

|

Max. Product Volume

|

(L)

|

250L

|

|

Dry cycle

|

(pc/h)

|

400

|

|

Screw Diameter

|

(mm)

|

120

|

|

Screw L/D ratio

|

(L/D)

|

30

|

|

Screw drive power

|

(KW)

|

90

|

|

Screw heating capacity

|

(KW)

|

40

|

|

No. of heating zone

|

(ZONE)

|

6~8

|

|

Max. Output of HDPE

|

(Kg/hr)

|

350

|

|

Oil pump drive power

|

(KW)

|

30

|

|

Clamping force

|

(KN)

|

1000~1200

|

|

Platen distance

|

(mm)

|

650

|

|

Mold moving stroke

|

(mm)

|

800-1800

|

|

Max. Size of Mold(W*H)

|

(mm)

|

1300x1800

|

|

Max. Die diameter

|

(mm)

|

400

|

|

Die heat capacity

|

(KW)

|

32

|

|

No. of Die heating zone

|

(ZONE)

|

4~6

|

|

Central distance of Double head

|

(mm)

|

/

|

|

MOOG Parison controller power

|

(KW)

|

4

|

|

Average Power Consumption

|

(KW)

|

272

|

|

Blowing pressure

|

(Mpa)

|

1.0—1.4

|

|

Air volume

|

(M3/MIN)

|

2.8

|

|

Cooling water pressure

|

(Mpa)

|

1

|

|

Water consumption

|

(L/MIN)

|

100

|

|

Size of machine ( L*W*H)

|

(m)

|

7.80*3.60*5.40

|

|

Weight of machine

|

(TON)

|

38

|

Mold Details

Company Introduction

Zhangjiagang U Tech Machine is a professional manufacturer of Extrusion Blow Molding Machines, owning more than 15 years working experience in EBM machines' design, manufacturing, overhauling, service and project solutions. Our machines are widely used in packing and producing industries of chemical, food & drinking, medical, automobile, traffic safety, recreation facility, family life and communal facilities.We have mature technology and technics for multi-layer co-extrusion, high speed and high automatic blow molding machines, also can help our customers for producing line layout and producing flow arrangement.

FAQ

Q1:Are you a trading company or a manufactory?

A1:We are a manufactory,can give u best service .

Q2:What’s your guarantee or the warranty of the quality if we buy your machines?

A2:We offer you high quality machines with 2 years guarantee . we will give u spare part free in 2 years

Q3:When can I get my machine after I paid?

A3:We will deliver the machines on time as the date we agreed both side.

Q4:How can I install my machine when it arrives?

A4:We will send our engineer to your side as soon as you get all your machines ready , for testing and teaching your technicians how to run the machines.

Q5:How about the spare parts?

A5:After we deal down all the things , we will offer you a spare parts list for your reference.

Q2:What’s your guarantee or the warranty of the quality if we buy your machines?

A2:We offer you high quality machines with 2 years guarantee . we will give u spare part free in 2 years

Q3:When can I get my machine after I paid?

A3:We will deliver the machines on time as the date we agreed both side.

Q4:How can I install my machine when it arrives?

A4:We will send our engineer to your side as soon as you get all your machines ready , for testing and teaching your technicians how to run the machines.

Q5:How about the spare parts?

A5:After we deal down all the things , we will offer you a spare parts list for your reference.

Hot Searches